Needle-bar formula automobile battery grading cabinet

A technology of automobile battery and capacity dividing cabinet, which is applied in the field of capacity dividing cabinet, can solve the problems affecting battery cycle life and discharge performance, leaking battery, battery weight, etc., and achieves the effect of simple structure, lower system cost, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

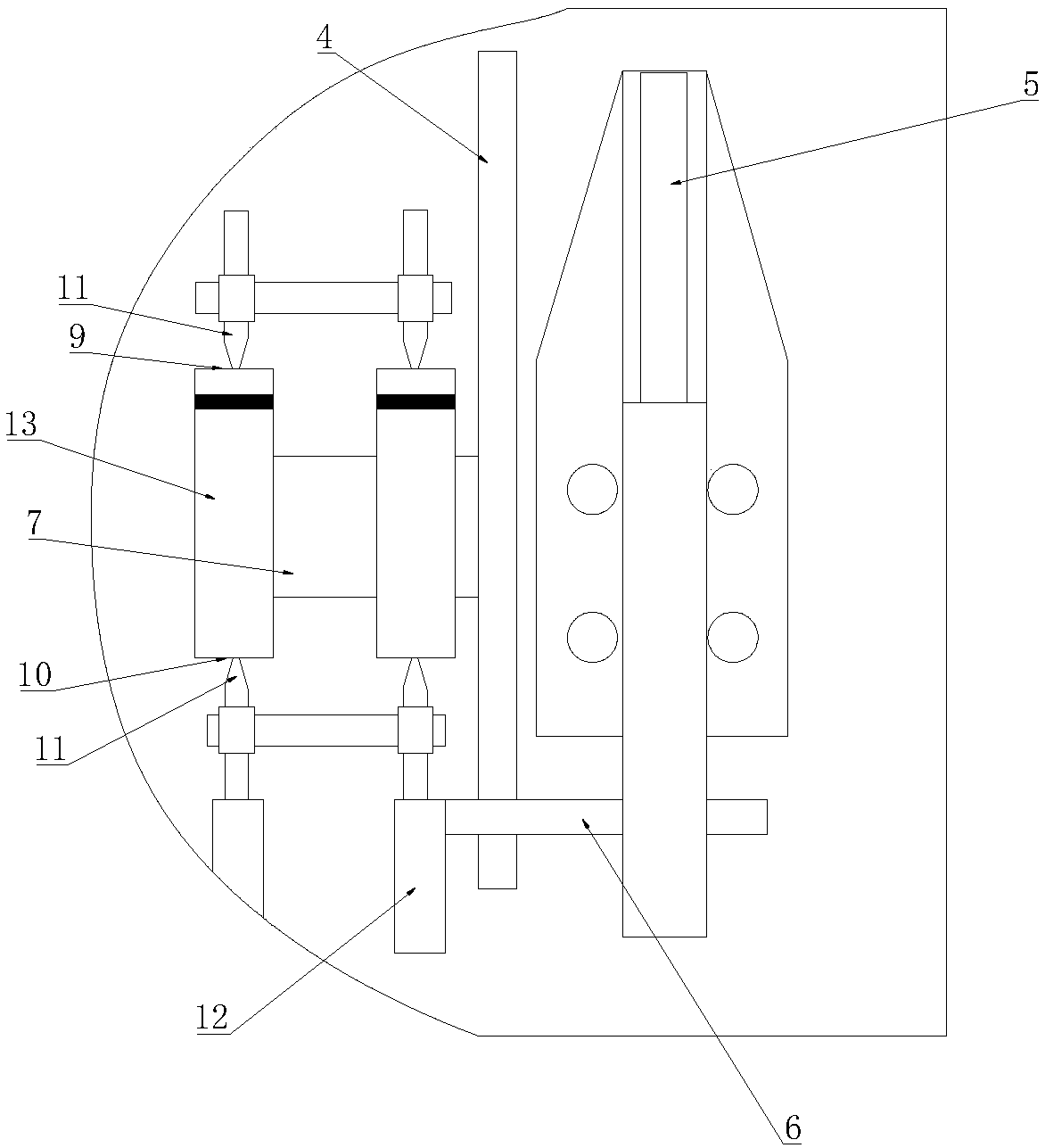

[0019] Such as figure 1 as shown, figure 1 In the bed of needles type automotive battery storage cabinet disclosed in the present invention, the battery clamping device uses elastic elements to connect the hinge device and the fixed frame, and the elastic elements can be deformed to improve the cycle life and discharge performance of the battery.

[0020] Below, the technical solution of the present invention will be described in detail through specific examples.

[0021] refer to figure 1 , the bed of needles type automotive battery storage cabinet proposed by the present invention includes a main body, a clamping device 7 for clamping the battery, and a control device arranged on the main body, the control device includes a transmission member, controls the transmission The control part and the control system of the movement of the part; the control part includes a manual elbow clamp 5 and a connecting part 6, one end of the connecting part 6 is fixedly connected to the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com