An electric bus charging joint device

A technology of charging joints and electric buses, which is applied in the direction of electric vehicle charging technology, electric vehicles, parts of connecting devices, etc., can solve problems that are contrary to vehicle weight reduction, energy saving and emission reduction, damage, and increase of vehicle load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

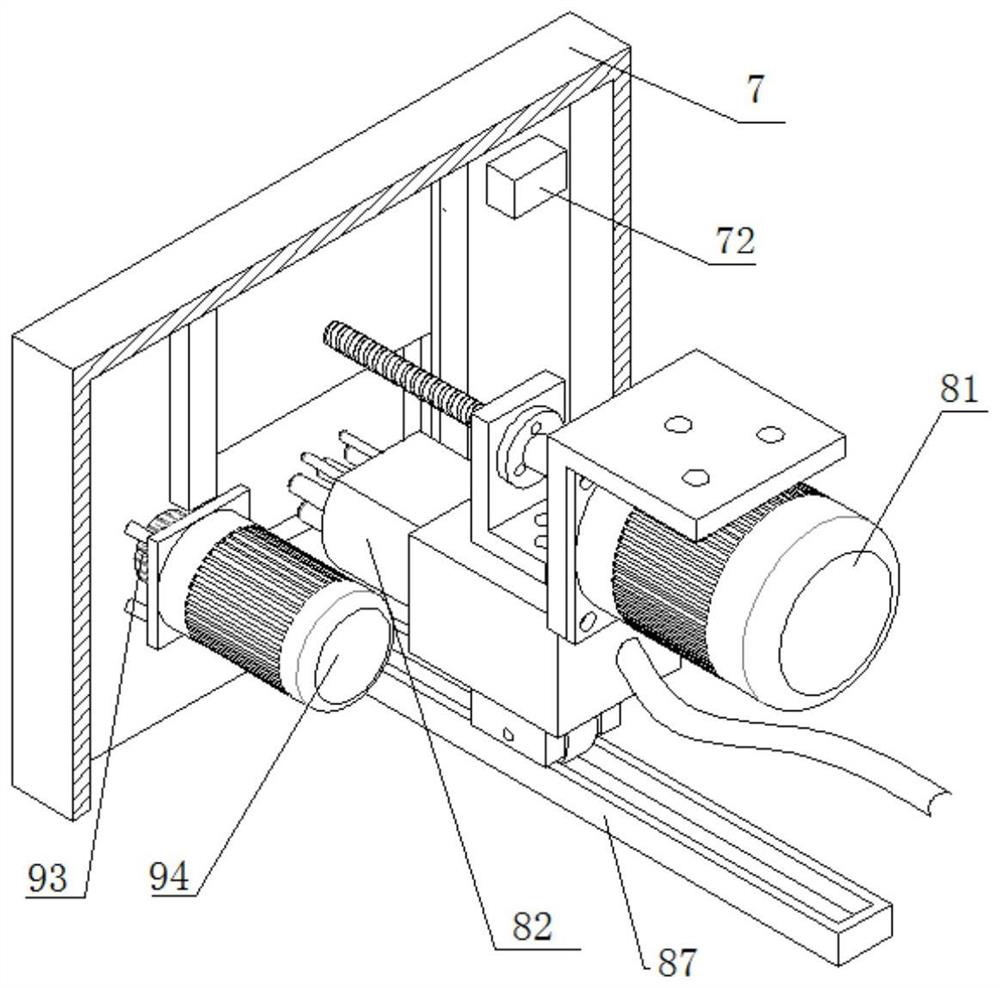

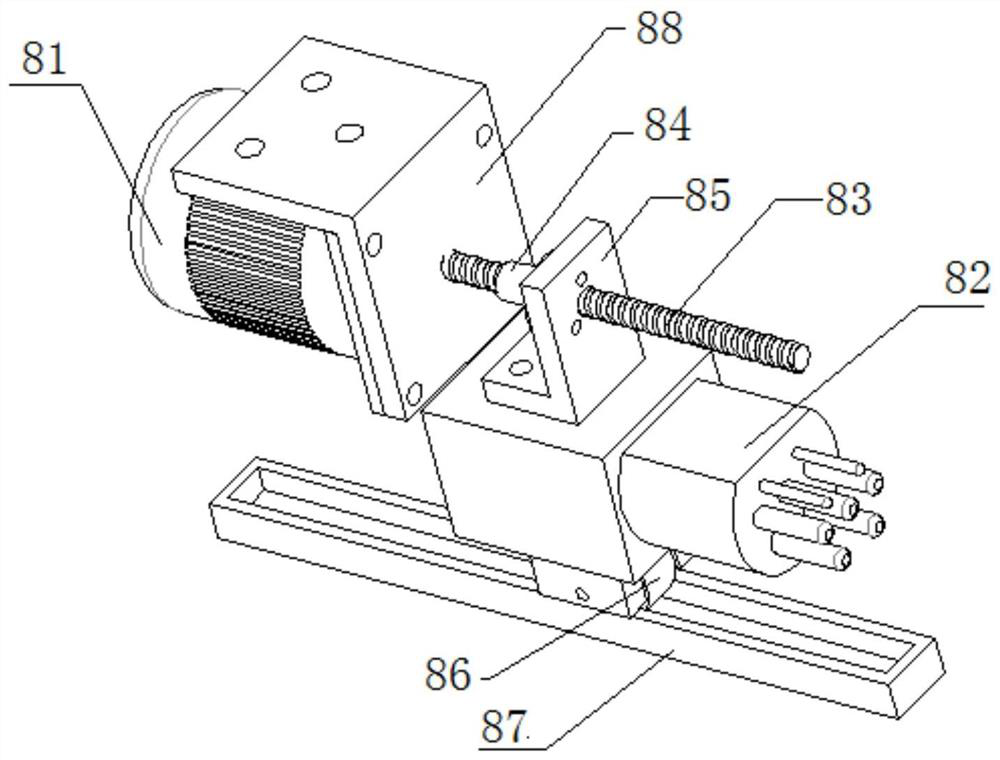

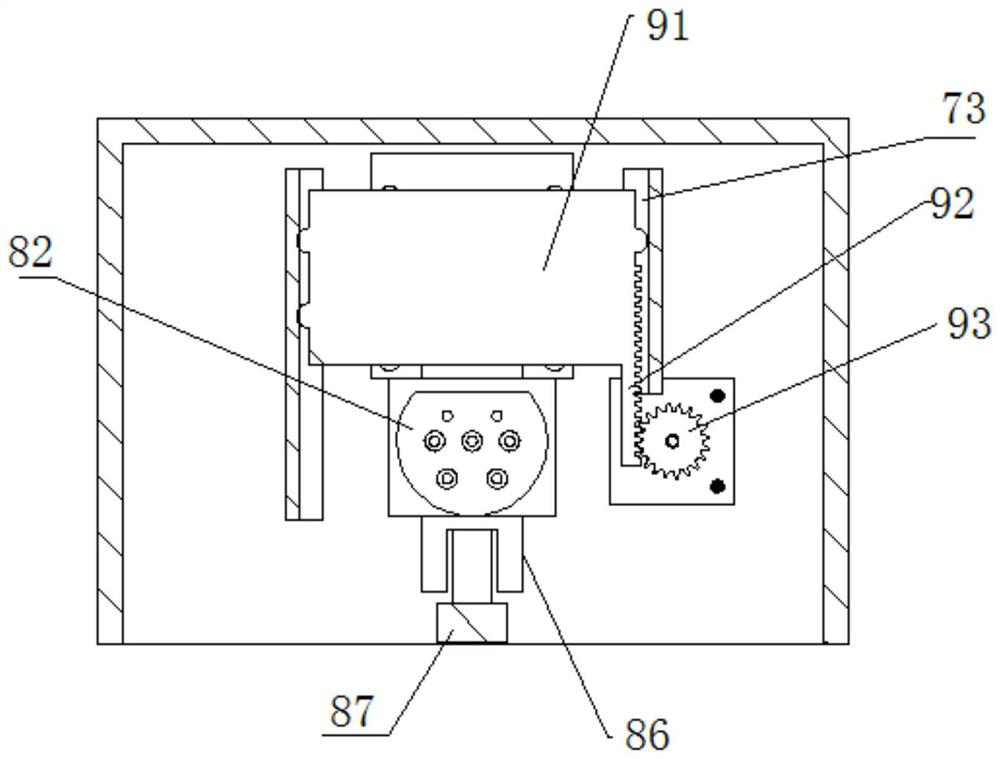

[0043] An electric bus charging connector device, such as Figure 1-5 As shown, it includes a charging connector box 7, a charging connector moving mechanism 8 and a flap lifting mechanism 9; the charging connector box 7 has an opening 71 for the charging connector to enter and exit; the charging connector moving mechanism 8 and the flap lifting mechanism 9 are both located at the charging connector Inside the box 7, the charging connector moving mechanism 8 includes a charging connector driving motor 81 that provides driving force. The charging connector driving motor 81 is fixed to the box body through a first connecting member 88, the charging connector 82, the lead screw 83 and the lead screw nut 84, The charging connector drive motor 81 is coaxial with the lead screw rod 83. The lead screw rod 83 engages with the lead screw nut 84 for transmission. The lead screw nut 84 is connected to the charging connector 82 through a connecting piece 85. A guide pulley 86 is provided und...

Embodiment 2

[0048] An automatic charging device for electric buses, such as Figure 6-9 As shown, the device is located above the bus station and includes a controller 1, an adjustment mechanism 2 and a positioning mechanism 3 arranged above the station; the adjustment mechanism includes a first arm 21, a second arm 22 and a charging interface 23, and the first arm 21 is fixed On the turntable 4, the turntable 4 rotates around the turntable shaft 41, the first arm servo motor 211 controls the movement of the first arm 21, the second arm servo motor 221 is fixed to the first arm 21, and the second arm servo motor 221 controls the movement of the second arm 22 , The second arm 22 is fixed to the interface servo motor 231, the interface servo motor 231 is connected to the connecting piece 233, the charging interface 23 is connected to the interface rotating motor 232, the interface rotating motor 232 is fixed to the connecting piece 233; the charging interface 23 is provided with a positioning ...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 2 is that multiple charging ports are provided, and multiple charging ports are connected in series. Such as Figure 13-15 As shown, the charging interface 23 is provided with a first charging interface 234, a second charging interface 235 and a third charging interface 236, the first charging interface 234, the second charging interface 235 and the third charging interface 236 are connected in series in sequence.

[0063] The upper end of the second charging port 235 is provided with a vertical ultrasonic probe 313, the first charging port 234 is provided with a first horizontal ultrasonic probe 311, and the third charging port 236 is provided with a second horizontal ultrasonic probe 312, which is stepped vertically. The motor 333 drives the vertical ultrasonic probe 313 to rotate, the first horizontal stepping motor 331 drives the first horizontal ultrasonic probe 311 to rotate, and the second horizontal stepping moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com