Pulse driving circuit based on vertical cavity surface emitting laser

A technology of vertical cavity surface emission and pulse drive, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., and can solve the problems of slow laser drive speed, inability to produce fast frontier, high repetition frequency, and high-power laser narrow pulses, etc. It achieves the effect of convenient pulse large current output, simple structure, and reduced loop impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

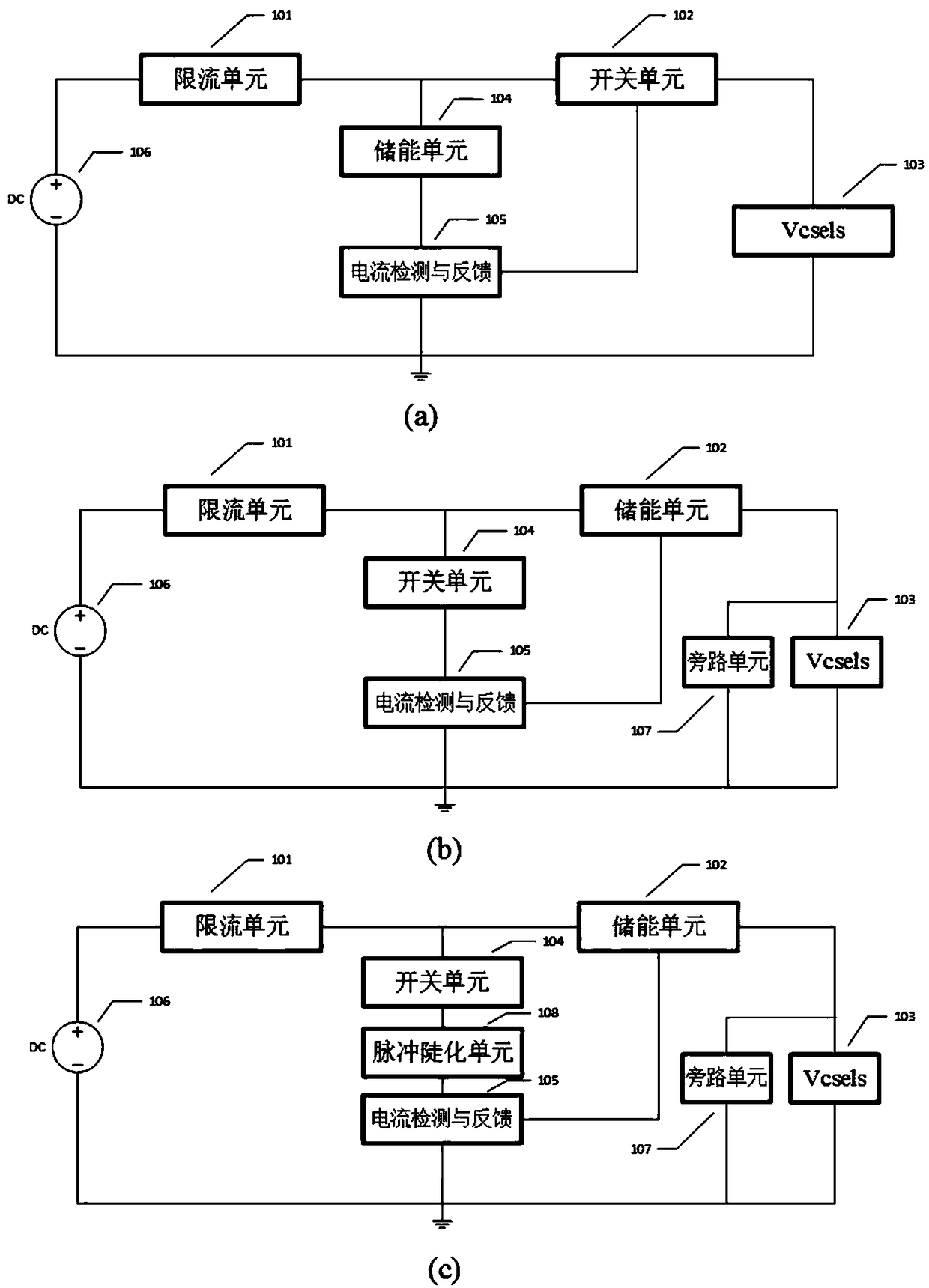

[0023] figure 1 It contains three drive circuit structures based on vertical cavity surface emitting lasers.

[0024] figure 1 In (a), the current limiting unit 101 is connected in series with the DC charging power supply 106, the switch unit 102 is connected to one end of the vertical cavity surface emitting laser Vcsels 103, and the current detection unit 105 is connected to the other end of the vertical cavity surface emitting laser Vcsels 103; the current detection unit 105 Usually, it is connected in series with the energy storage unit 104, and the discharge current and the charging current of the energy storage unit 104 can be measured. The charging circuit of the entire circuit is composed of a DC charging power supply 106, a current limiting unit 101, an energy storage unit 104 and a current detection unit 105, and the discharge circuit is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com