Gravitational field distributed type bottom pouring method for numerical control gantry-type milling beam

A gravitational field, distributed technology, applied in the components of the mold, equipment for feeding molten metal into the mold, and casting molding equipment, etc. Stable filling and the effect of reducing metal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

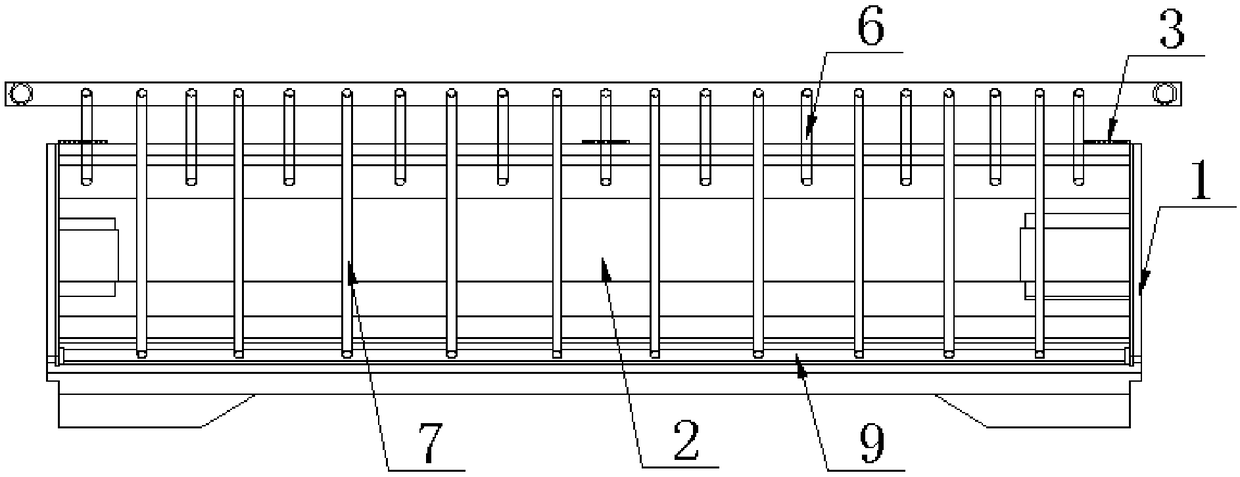

[0030] The present invention provides such Figure 1-4 Shown is a distributed bottom injection method under the gravity field of CNC gantry milling beam, and its specific operation steps are:

[0031] Step 1: Mold 1 installation: Fix the mold 1 on the workpiece pouring table;

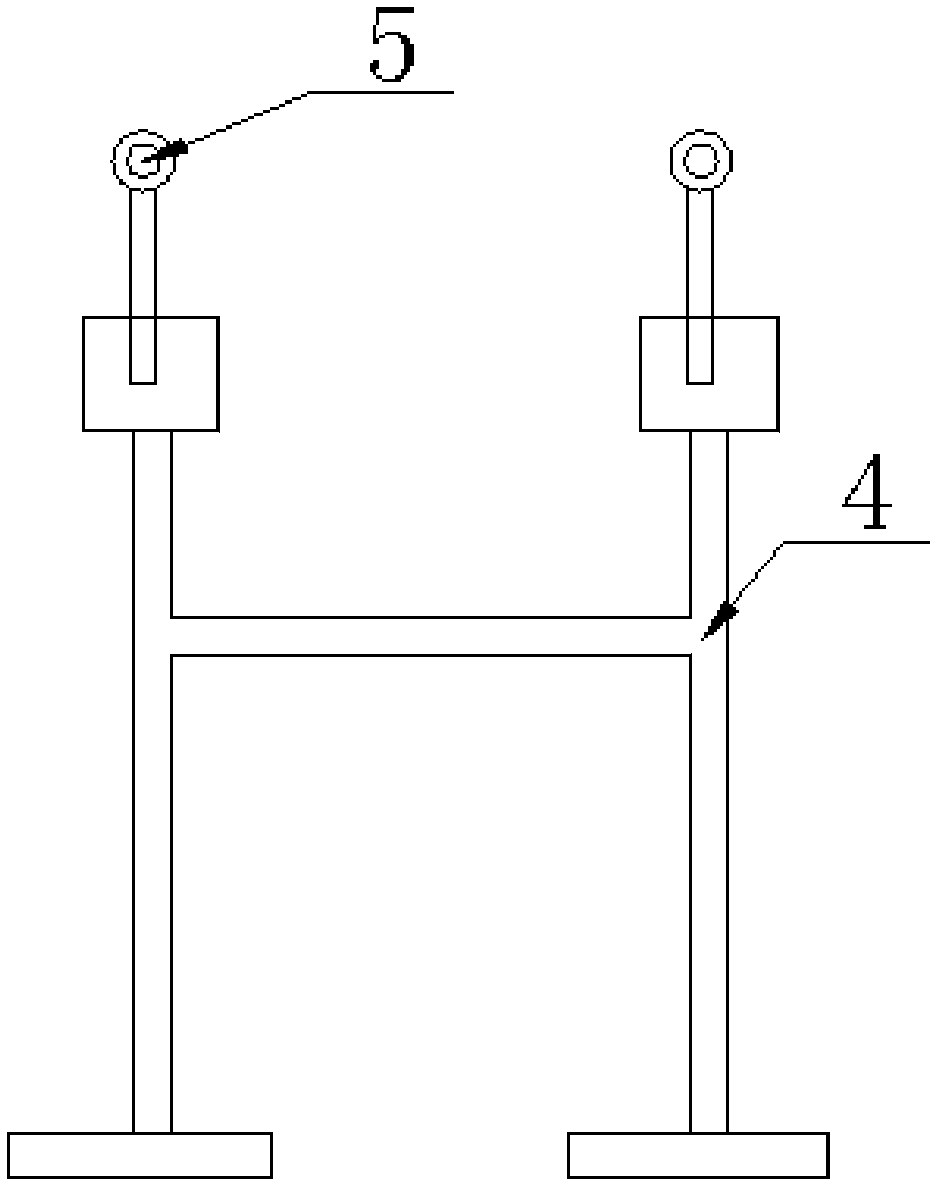

[0032] Step 2: Manufacture of core bone 4: Pre-cast the core bone 4 and lifting lug 5 into an integral shape, so as to be used in the process of making the clay core 2;

[0033] Step 3: Making the clay core: making the clay core 2 with the precast overall shape of the core bone 4 and the lifting lug 5 as the skeleton;

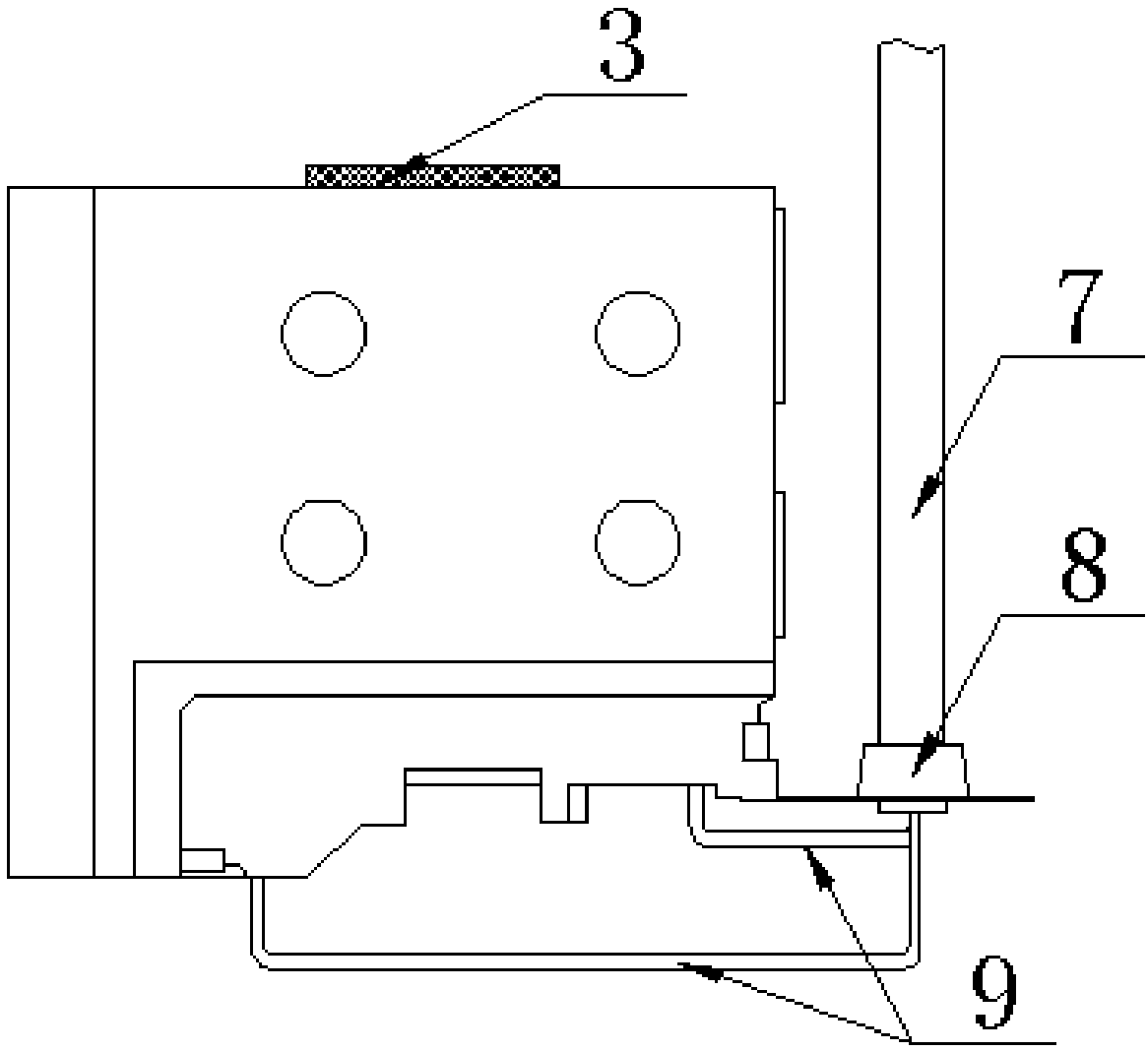

[0034] Step 4: Hanging the core: use the hook 6 to hook the lifting lug 5, and hang the mud core 2 into the cavity of the mold 1;

[0035] Step 5: Pouring: The molten iron is introduced from the sprue 7, passed through the runner 8, dispersed into the cavity of the mold 1 through the ingate 9, and the pouring temperature is 1300°C. The pouring method of pouring and slow closing to the...

Embodiment 2

[0043] The difference from Example 1 is that in step five, the molten iron is introduced from the sprue 7, passed through the runner 8, dispersed through the ingate 9, and enters the cavity of the mold 1 in a balanced manner, wherein the pouring temperature is 1400 ℃, at the same time, adopt the pouring method of steady opening and fast injection, and slow closing to the top for pouring, that is, the iron nozzle is opened smoothly, and the pouring flow is opened from 1 / 3 to 1 / 2 of the opening to the Full flow, and after the opening of the flow, it can only accelerate steadily, and cannot close the flow. When the pouring height is 180-250mm after the opening is full, pour at full speed, and the injection speed should be greater than 350mm / min, so as to improve the surface quality. When the pouring height is 150-250mm, start to collect the flow to make the liquid level level and rise slowly. If the flow is too early, the surface quality of the workpiece will be poor. If the flow ...

Embodiment 3

[0045] The difference from Example 1 and Example 2 is that in step five, the molten iron is introduced from the sprue 7, passed through the runner 8, dispersed and evenly entered into the cavity of the mold 1 through the ingate 9, wherein the pouring The temperature is 1500°C. At the same time, the pouring method of steady opening and fast injection and slow closing is adopted for pouring, that is, the iron nozzle is opened smoothly, and the pouring flow is changed from 1 / 3 to 1 / 3 of the opening flow within 20 to 50 seconds. 2. The flow is opened to full flow, and after the flow is opened, it can only be accelerated steadily, and the flow cannot be closed. When it is fully opened and the distance from the pouring height is 180-250mm, pour at full speed, and the injection speed should be greater than 350mm / min, so as to improve the surface quality. , when the distance from the pouring height is ≥ 250mm, start to collect the flow to make the liquid level level and rise slowly. If...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com