Construction technology of one-time molding of concrete pouring on top of construction column and construction device thereof

A technology for construction devices and structural columns, which is applied in the direction of building structures, columns, pier columns, etc., can solve the problems of restricting construction efficiency, manual removal, time-consuming, etc., achieve strong turnaround, convenient disassembly and installation, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

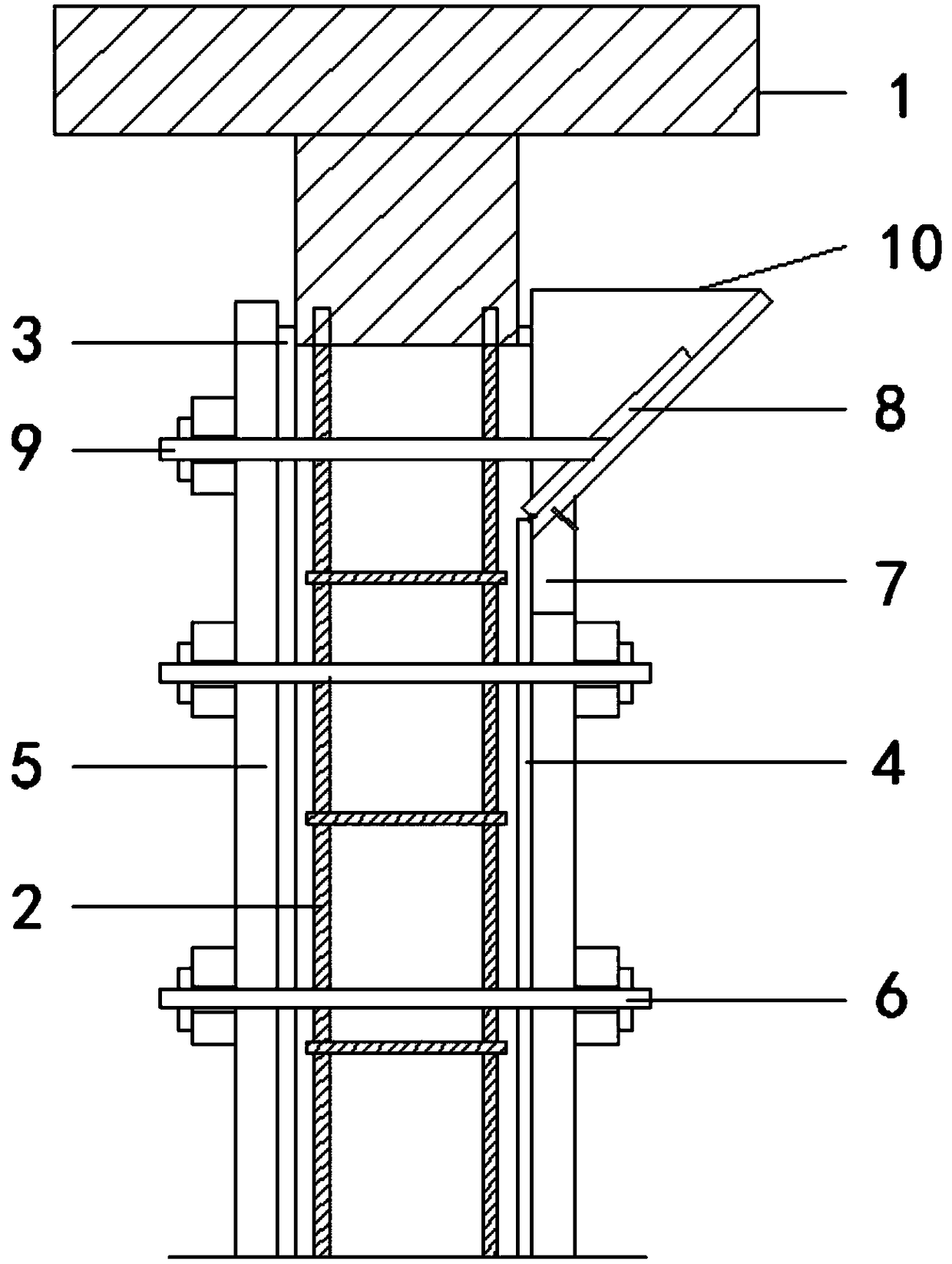

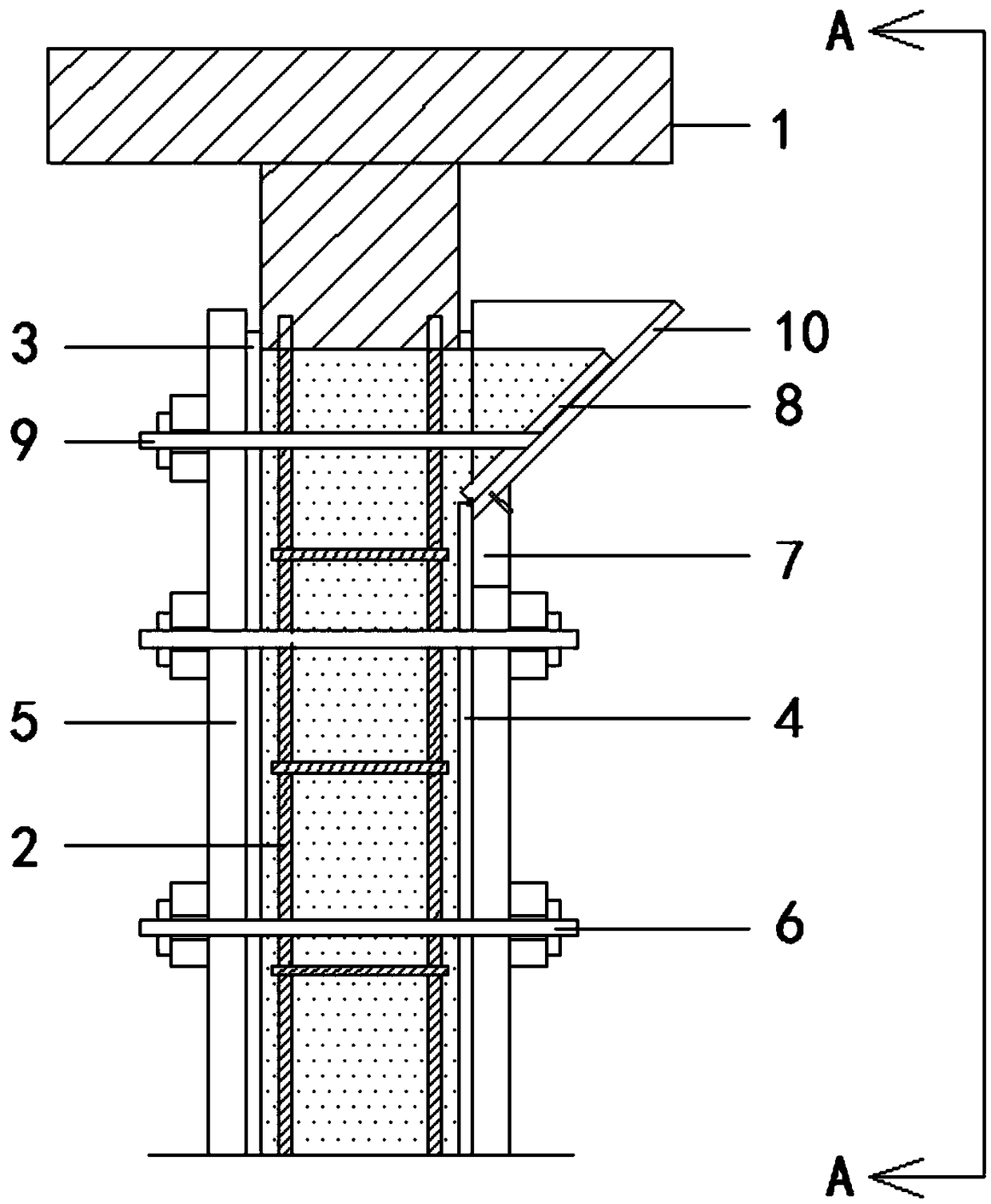

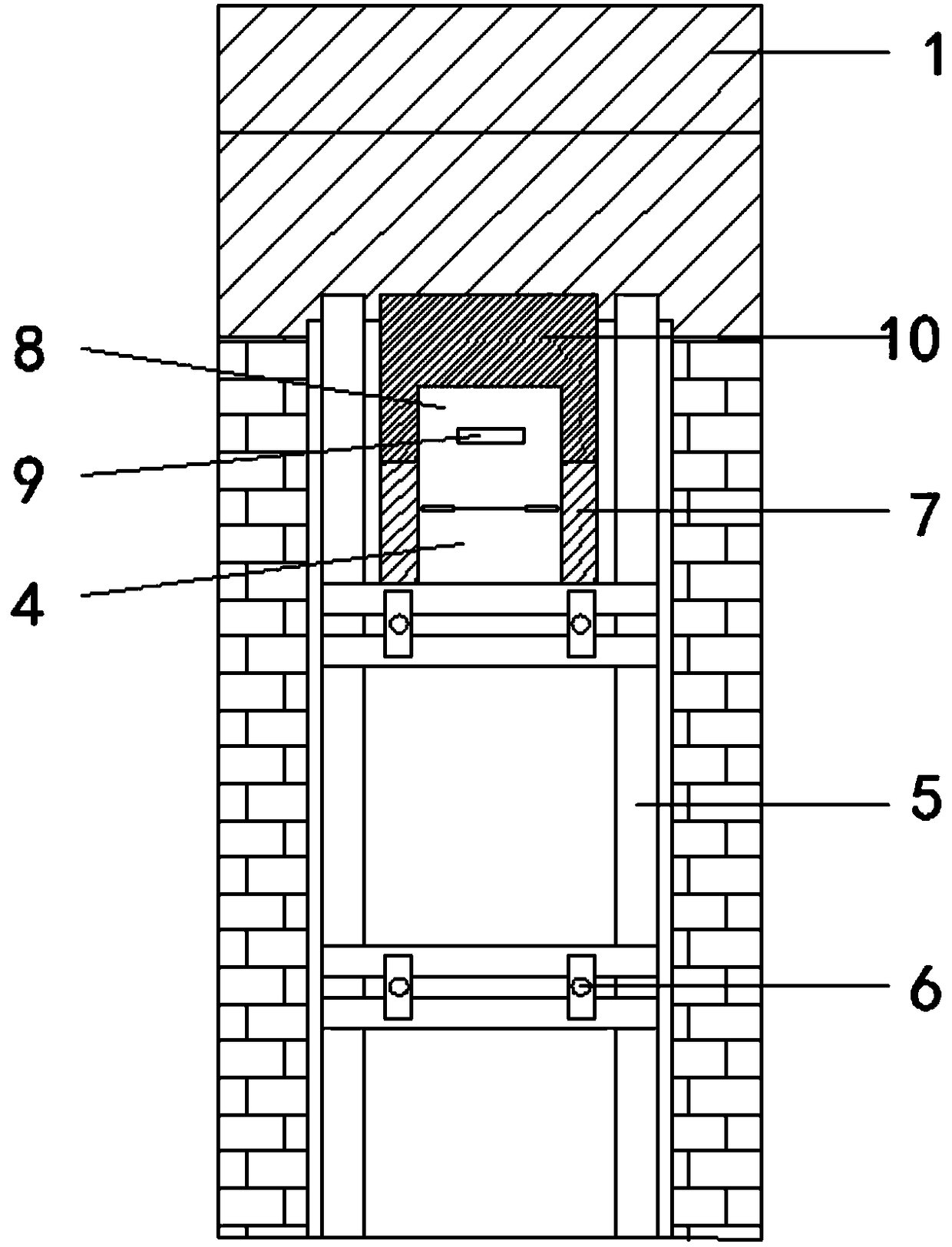

[0065] A construction device for one-time forming of concrete pouring on the top of a structural column, comprising: concrete beam slab 1, steel cage 2, first structural column template 3, second structural column template 4, template wooden square 5, lower hopper support wooden square 6, pair The tie rod 7, the movable closing plate 8, the closing screw 9, the shaped lower hopper 10; the lower part of the concrete beam slab 1 is provided with a reinforcing steel cage 2, and the reinforcing steel cage 2 and the concrete beam slab 1 are connected by anchoring; the two sides of the wall are respectively The first structural column template 3 and the second structural column template 4 are provided; the outer sides of the first structural column template 3 and the second structural column template 4 are provided with a template wood 5; the pair of tie rods 7 penetrate the first structural column template 3 and the second The second structural column template 4, and the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com