Single-row flue gas waste heat recovery device

A technology of flue gas waste heat and recovery device, applied in heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of exhaust heat loss and slow progress in recovering flue gas waste heat, and achieve high waste heat recovery rate , the effect of low mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

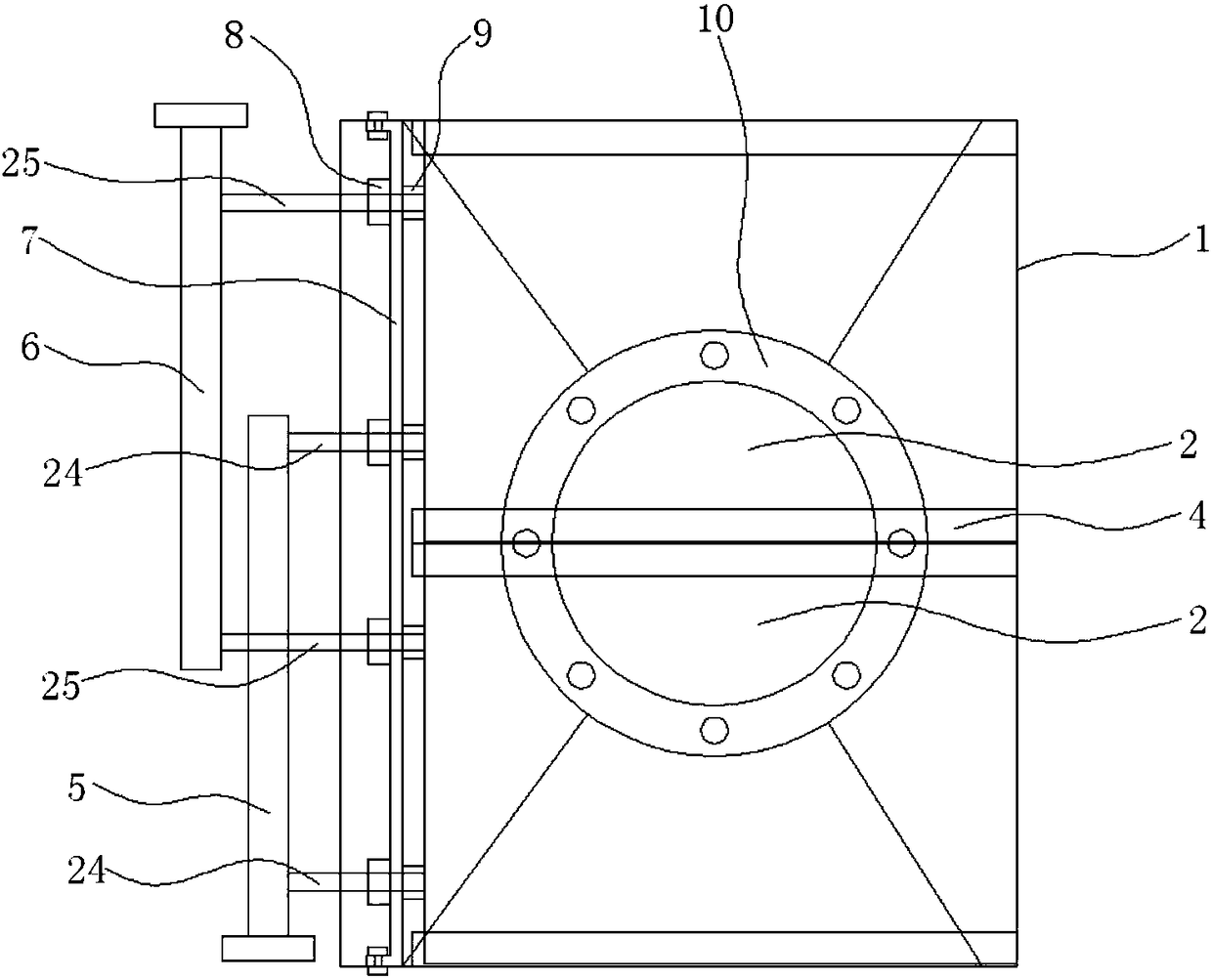

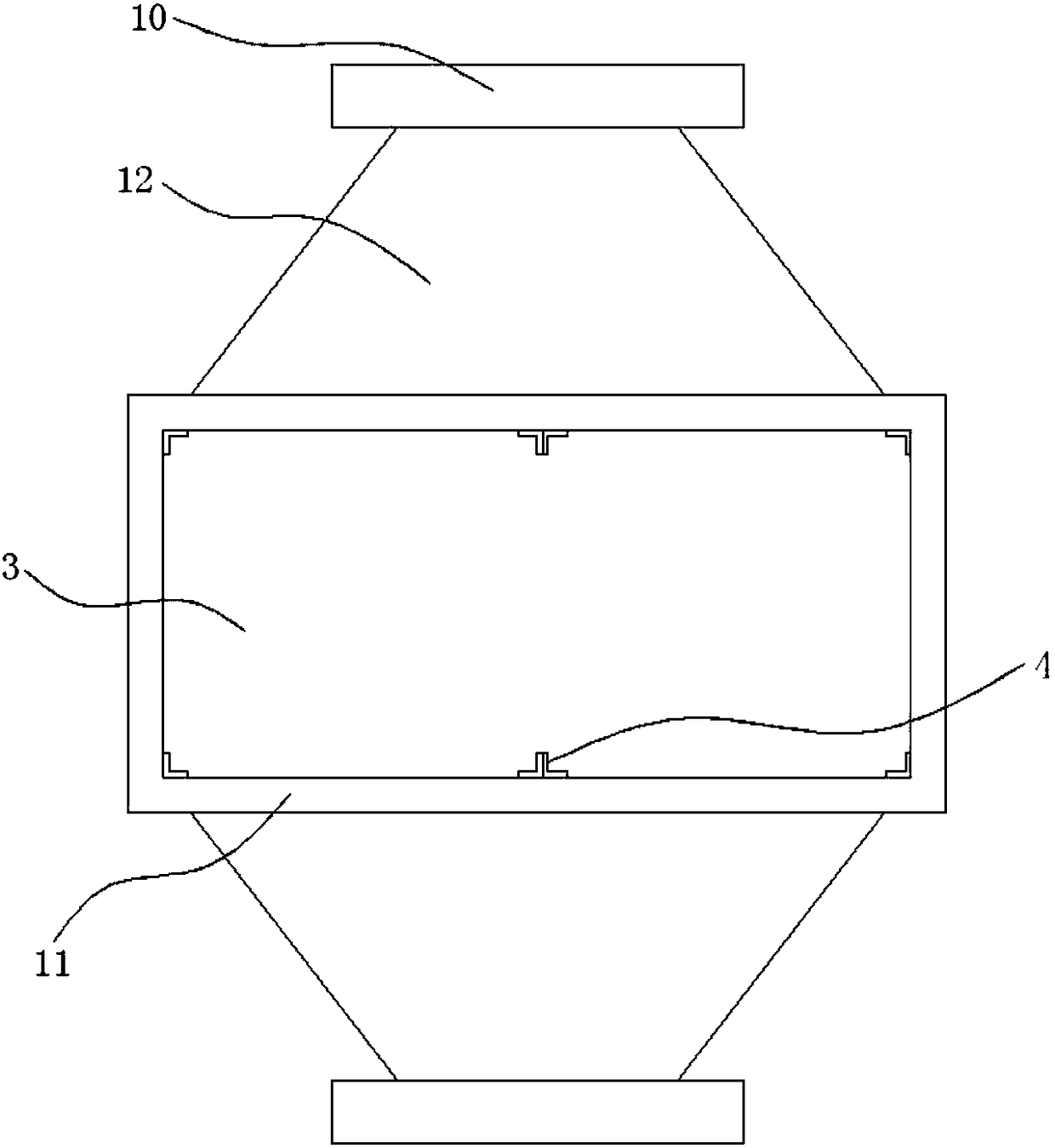

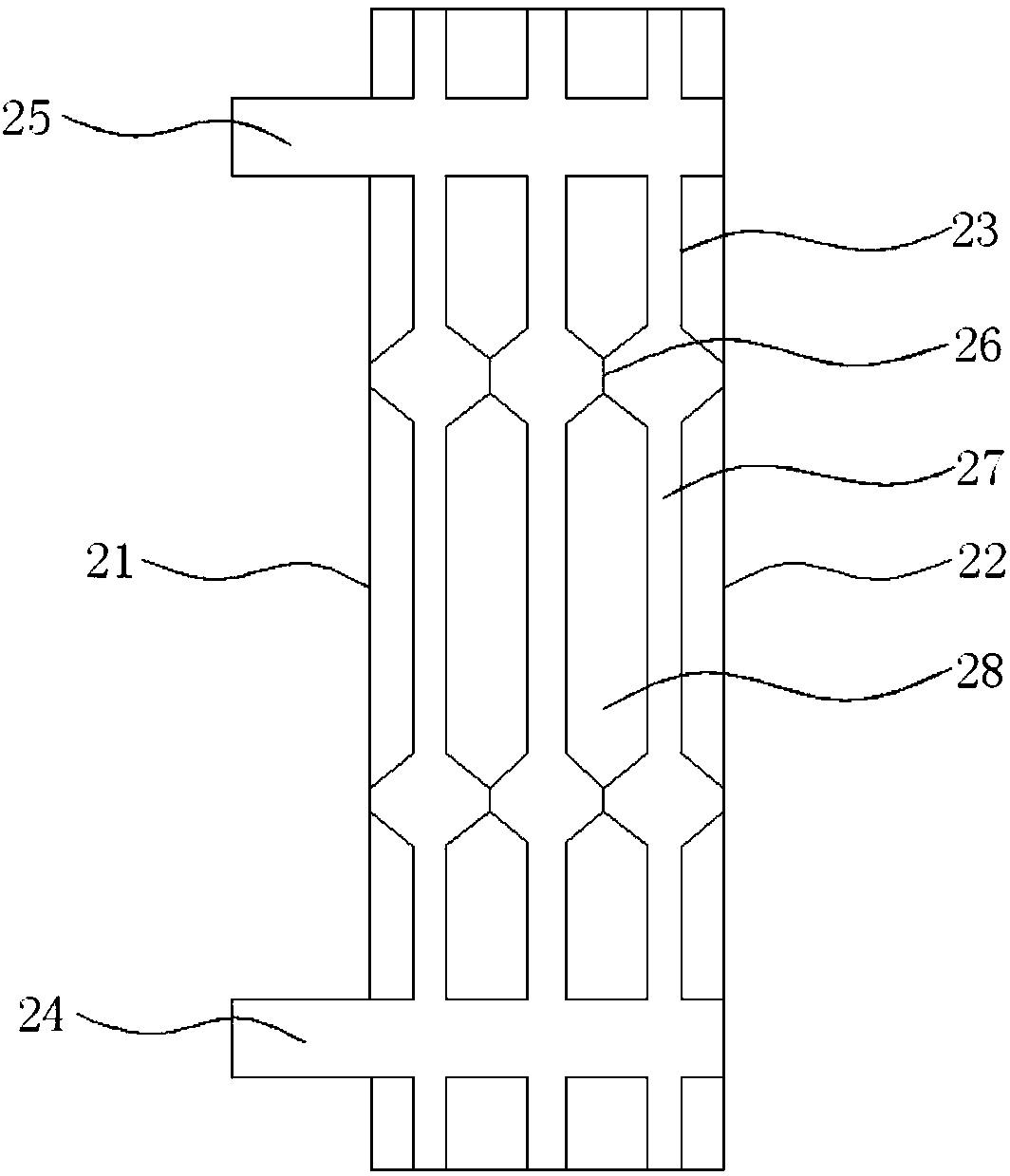

[0018] like Figures 1 to 3 As shown, the embodiment of the present invention provides a single row flue gas waste heat recovery device, the device is connected to the boiler flue, it includes a shell 1, and the shell 1 is provided with more than two gas-liquid heat exchangers 2 , generally set to 2 to 5, and can be adjusted according to actual needs. The gas-liquid heat exchangers 2 are horizontally arranged in a row. The gas-liquid heat exchanger used in the embodiment of the present invention can be various in the prior art, and the preferred gas-liquid heat exchanger includes a fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com