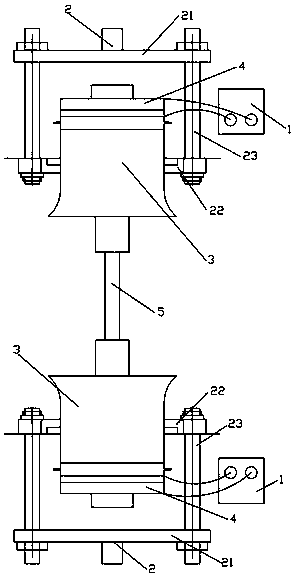

Ultrasonic wave assisted stretching device and method

A technology of auxiliary stretching and stretching devices, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as difficult to simulate service environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] Generally, the discussion of the constitutive relation of materials refers to the distortion properties of the material, so the discussion of the constitutive relation involves the equivalent shear stress and equivalent shear strain, that is, the deviating part of the stress and strain tensor, The research on the spherical part of the stress and strain tensor belongs to the research scope of the equation of state; at the same time, the tensile test is one of the most commonly used methods to study various mechanical parameters of materials. Under the constitutive relationship and the changes of various mechanical performance parameters compared with normal tension, this application applies ultrasonic vibration to the workpiece 5, and carries out ultrasonic-assisted stretching tests to obtain the mechanical characteristics of the material. This application The tensile test is mainly carried out on No. 2219 aluminum alloy or No. 20 steel. No. 2219 aluminum alloy is often u...

Embodiment 1

[0026] Example 1. Ultrasonic-assisted tensile test on No. 2219 aluminum alloy

[0027] Step 1. Prepare ultrasonic generator 1: According to the material to be tested and the environmental parameters of the material to be used, select an ultrasonic source with a power supply voltage of 220V, a frequency of 50Hz, a maximum output power of 3000W, and an adjustable frequency range of 20KHz to 40KHz.

[0028] Ultrasonic generator 1, also known as ultrasonic frequency generator, is an energy source for supplying ultrasonic electric energy to ultrasonic transducer 4. Its function is to convert alternating current into ultrasonic frequency electric power output to provide the energy required for workpiece 5 to vibrate when stretched by ultrasonic vibration. . It is mainly composed of oscillators, voltage amplifiers, power amplifiers and output transformers. Among them, the oscillator is the heart of the ultrasonic generator 1 . In order to ensure the frequency stability of the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com