A test method and test combination device for battery separator puncture resistance

A test method and technology for battery diaphragms, which are applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of insufficient accurate evaluation of the puncture resistance of the diaphragm, neglect of the impact of the puncture resistance of the diaphragm, etc., and achieve comprehensive puncture resistance, Simple operation and good detection repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

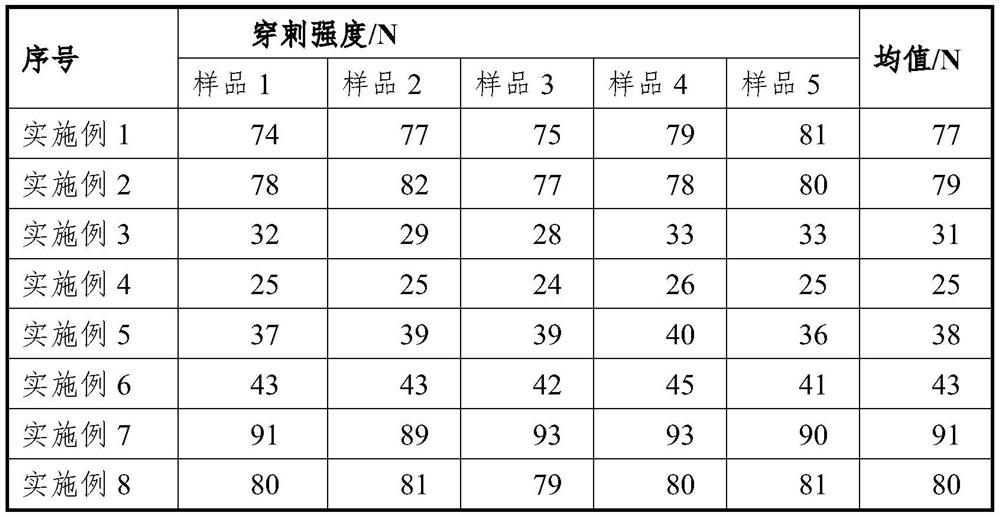

Embodiment 1

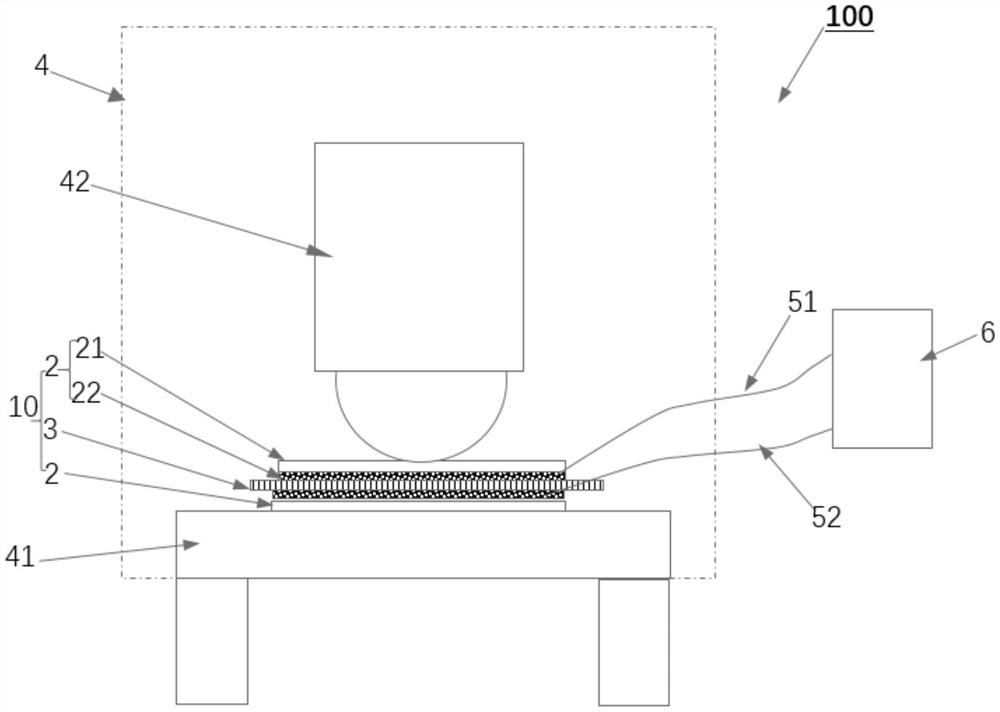

[0055]In this example, the high-temperature puncture strength of a polyethylene wet-processed membrane with a thickness of 16 μm is tested, and the process of battery baking is simulated to test the puncture strength of the diaphragm during battery baking. The specific operation steps are as follows:

[0056](1) Place the 120mm×120mm diaphragm sample on the upper and lower sides of 100mm×100mm copper foil with tiny burrs covering 30%-40% of the surface area (the non-burr surface is coated with insulating layer or pasted with insulating glue) ), the particle size of the burr on the copper foil is 50-80 μm, the height of the protrusion is 50-80 μm, and the burr surface faces the diaphragm sample. Bond the wire to the copper foil (bonded to the side without insulation layer or insulation film) and connect it to the insulation resistance tester, and then place the copper foil and diaphragm together on the test platform in the high and low temperature universal testing machine for insulatio...

Embodiment 2

[0059]In this example, the high-temperature puncture strength of a polyethylene wet-processed membrane with a thickness of 16 μm is tested, and the process of battery baking is simulated to test the puncture strength of the diaphragm during battery baking. The specific operation steps are as follows:

[0060](1) Place the 120mm×120mm diaphragm sample between the upper and lower dry sanding papers of 100mm×100mm, where the sand paper is 40μm tungsten carbide, and the wires are bonded to the sand layer of the two dry sanding papers Attach and connect with the insulation resistance tester, then put two dry sanding paper and diaphragm samples together on the test platform in the high and low temperature universal testing machine, and the insulation resistance tester is placed outside the high and low temperature testing machine.

[0061](2) The diaphragm sample is allowed to stand for 30 minutes in the high and low temperature testing machine at 80℃, and then press the upper dry sanding paper...

Embodiment 3

[0063]In this example, the low-temperature puncture strength of a polypropylene dry-process separator with a thickness of 40 μm is tested, simulating the low-temperature use environment of the battery, and the puncture strength of the separator during low-temperature charging and discharging of the battery is tested. The specific operation steps are as follows:

[0064] (1) Place the 120mm×100mm diaphragm sample between the upper and lower dry sanding papers of 90mm×80mm, where the sand paper is 80μm titanium carbide, and the wires are bonded to the two dry sanding paper grit surfaces Connect with the insulation resistance tester, then put two dry sanding paper and diaphragm samples together on the test platform in the high and low temperature universal testing machine, and the insulation resistance tester is placed outside the high and low temperature universal testing machine.

[0065](2) The diaphragm sample is allowed to stand for 60 minutes in the high and low temperature universal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com