Self-learning filter lifetime estimation method

A technology of filter and life, which is applied in the field of self-learning filter life estimation, and can solve problems such as filter rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The EDM machine needs to provide a sufficient amount of conditioned dielectric fluid dielectric units to implement the EDM process. The important function of the dielectric unit is the filtration of the dielectric fluid.

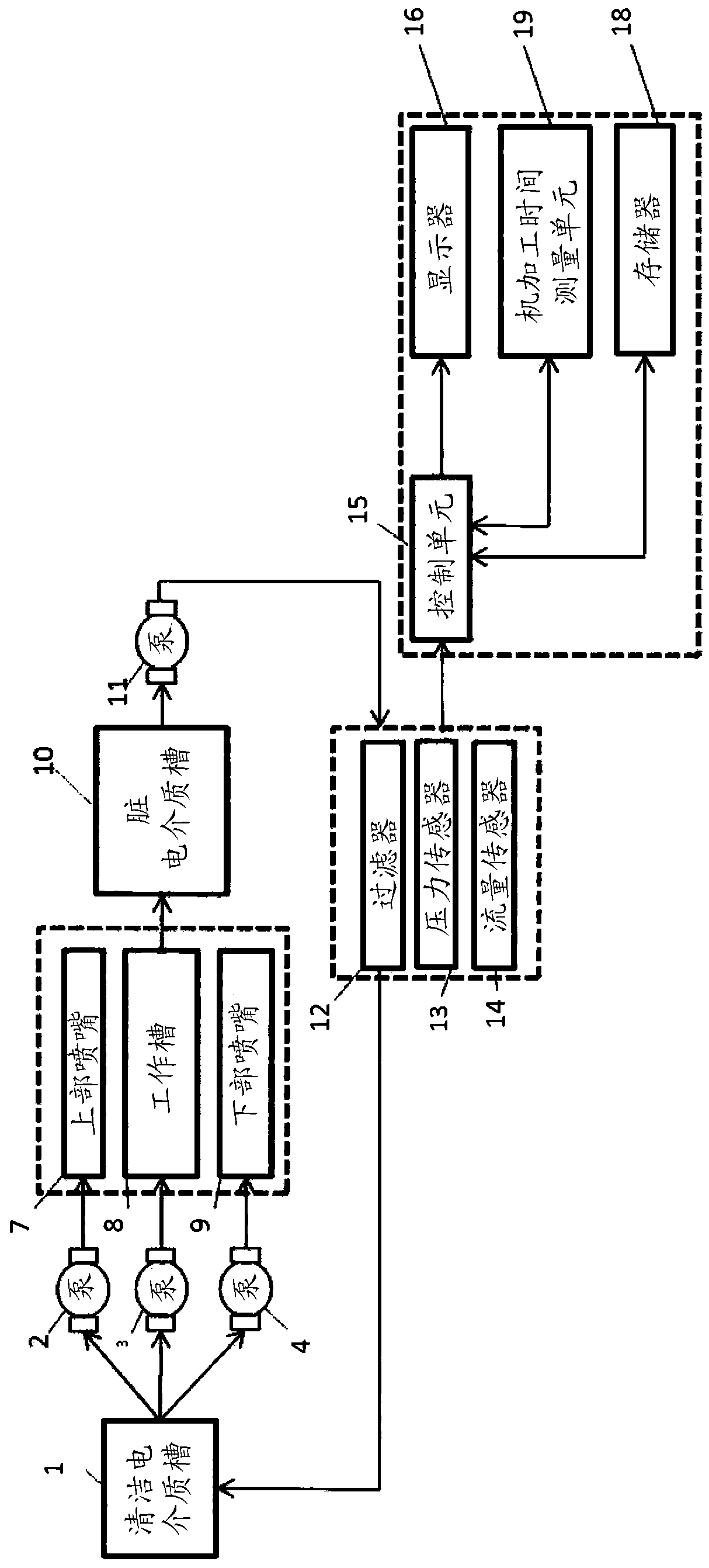

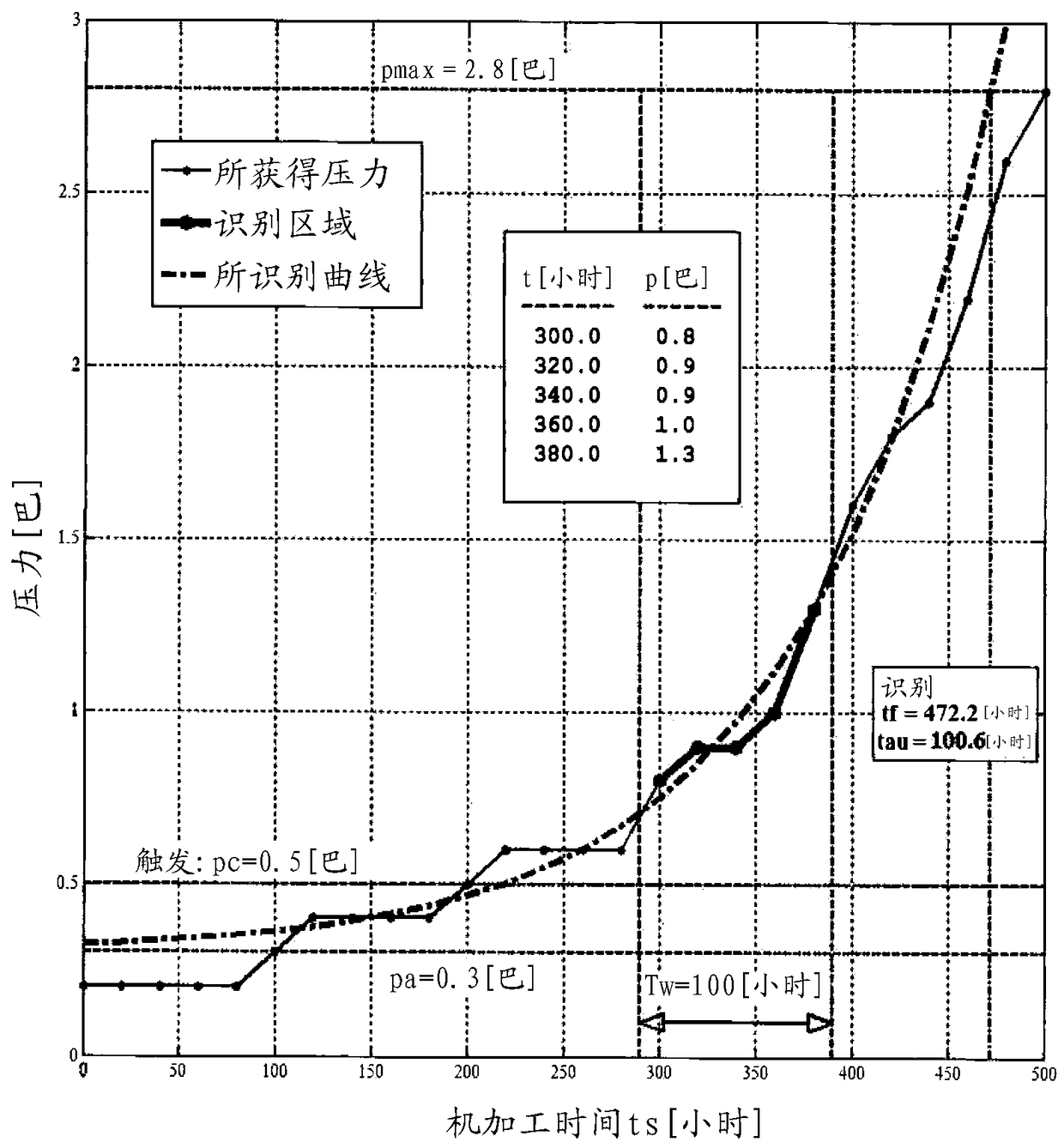

[0084] figure 1 A block diagram showing a typical wire EDM machine (wire EDM). The wire EDM machine includes a dielectric unit with a dirty dielectric tank 10 for collecting used dielectric fluid, a clean dielectric tank 1 for collecting conditioned dielectric fluid, and a filter circuit. The pump 3 is used to fill the working tank 8 and maintain the desired dielectric level in the working tank. In this representation, pumps 2 and 4 are used to deliver the dielectric fluid to the upper and lower nozzles at high pressure. In fact (not shown), there may be a high pressure pump controlled by a frequency converter and then a valve for controlling the dielectric fluid delivered to the upper and lower nozzles to flush the machining gap. Use CNC, axis contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com