Downhole optical fiber imaging camera

A camera and imaging technology, which is applied in petroleum and exploration fields, can solve the problems of low operating temperature of the instrument, reflection of particles, and high cost of going into the well, and achieve the effects of increasing the operating temperature, simplifying the structure of the instrument, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

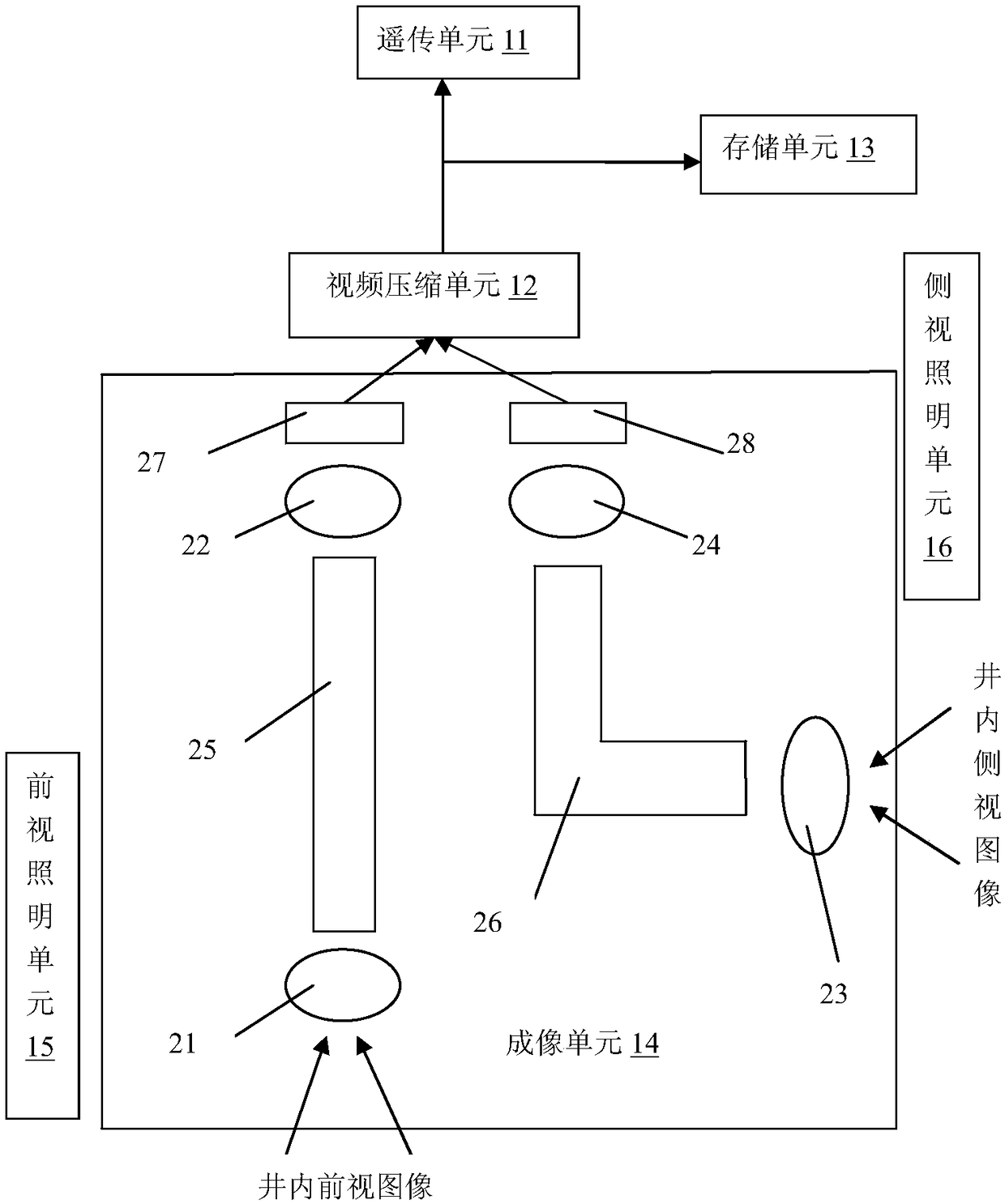

[0017] Such as figure 1 , figure 2 As shown, a downhole fiber optic imaging camera mainly includes a remote transmission unit 11, a video compression unit 12, a storage unit 13, an imaging unit 14, a front-view lighting unit 15, and a side-view lighting unit 16;

[0018] The output end of the imaging unit 14 is connected to the video compression unit 12, one end of the output end of the video compression unit 12 is connected to the remote transmission unit 11, and the other end is connected to the storage unit 13.

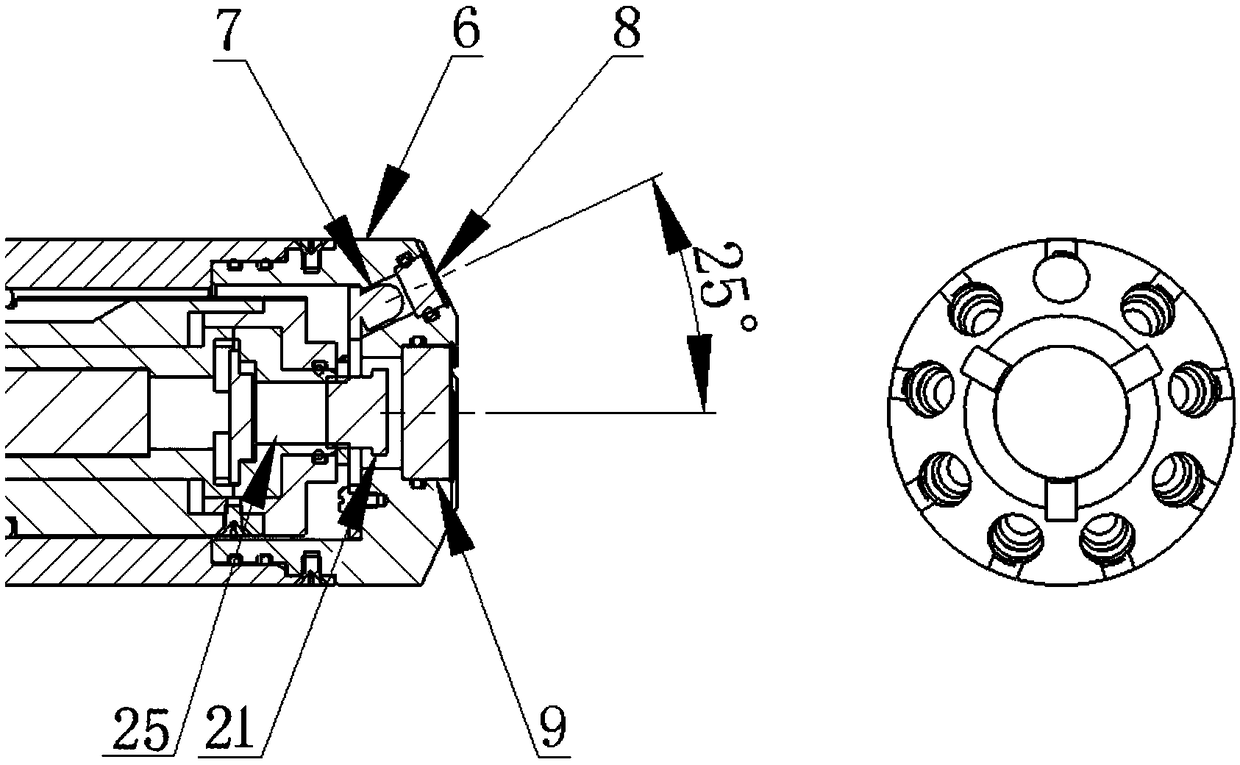

[0019] Front-view camera includes lens one 21, imaging fiber one 25, lens two 22, photosensitive chip one 27, side-view camera includes lens three 23, imaging fiber two 26, lens four 24, photosensitive chip two 28, lens one 21 and lens three The front ends of 23 are equipped with translucent sapphire glass resistant to high temperature and pressure.

[0020] The lighting unit includes a front-view lighting module and a side-view lighting module. The front-view lighting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com