Carbonylation reactor of device for synthesizing gas to produce ethylene glycol

A technology of ethylene glycol and synthesis gas, applied in the direction of carbon monoxide or formate reaction preparation, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the inability to use radial reactors for ethylene glycol hydrogenation, and achieve Improve maneuverability, reduce power cost, and reduce pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will further illustrate the present invention in conjunction with the accompanying drawings and embodiments.

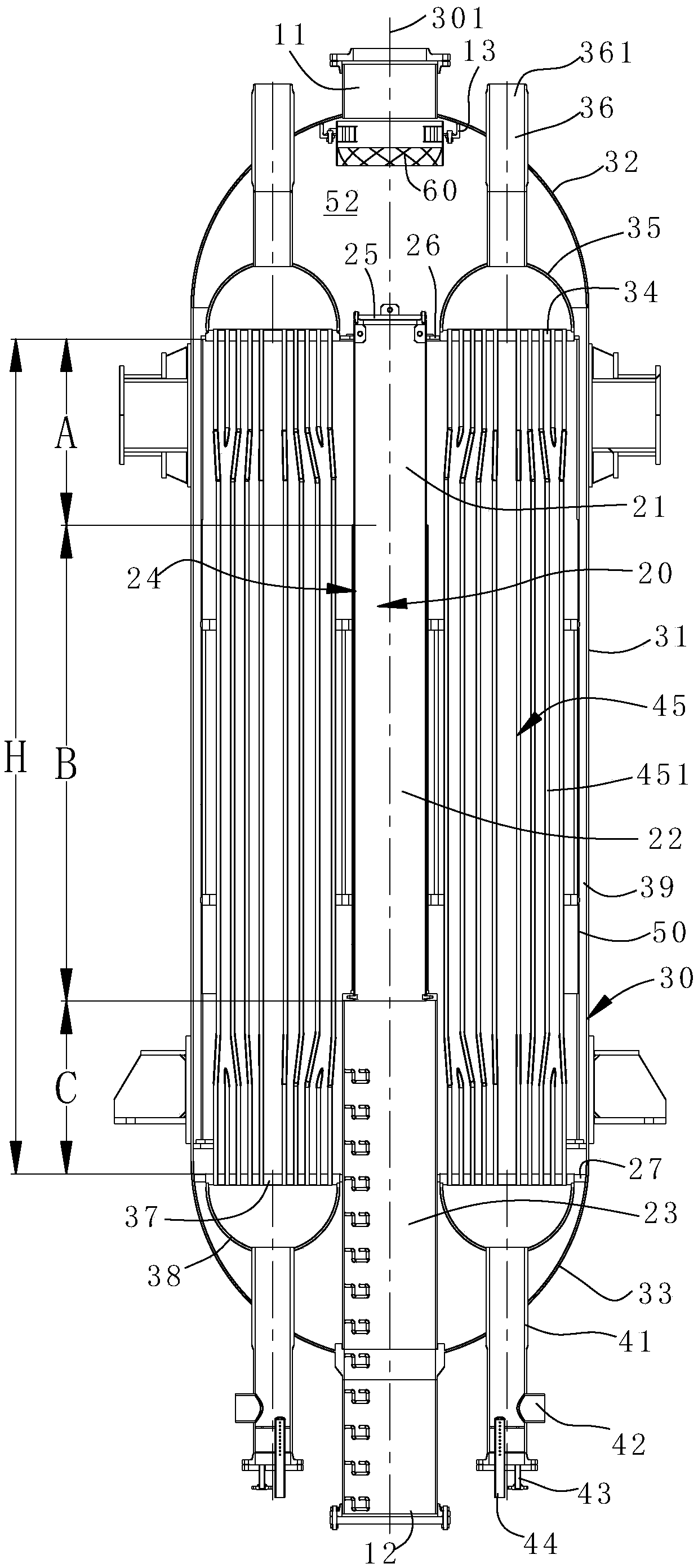

[0029] see figure 1 , the carbonylation reactor of the synthesis gas to ethylene glycol plant, which has a shell 30, and the shell 30 includes a cylindrical shell 31, an upper head 32 installed on the top of the shell 31 and an upper seal installed on the shell The lower head 33 at the bottom. An air inlet 11 and four refrigerant outlets 361 arranged around the air inlet 11 are installed on the top of the upper head 32, and an exhaust port 12 is installed on the bottom of the lower head 33, four outlets with The refrigerant inlet pipe 41 corresponding to the refrigerant outlet.

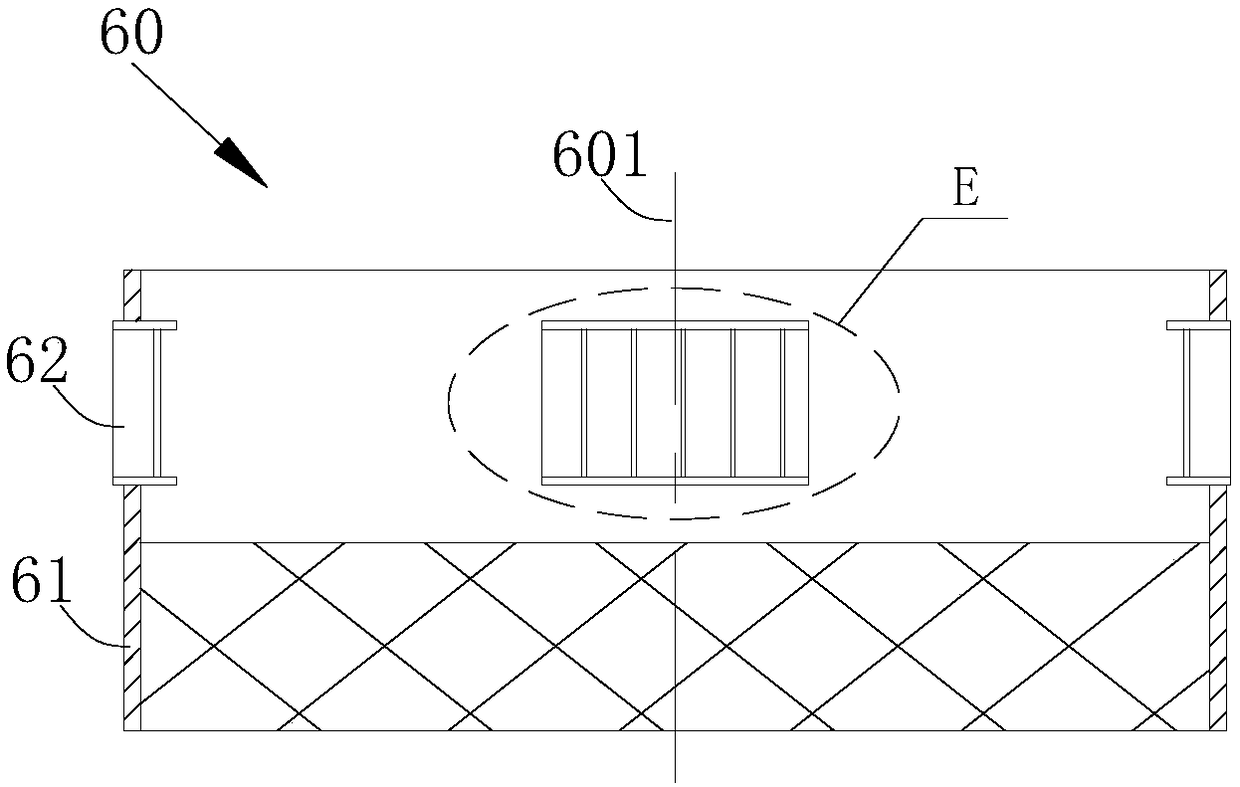

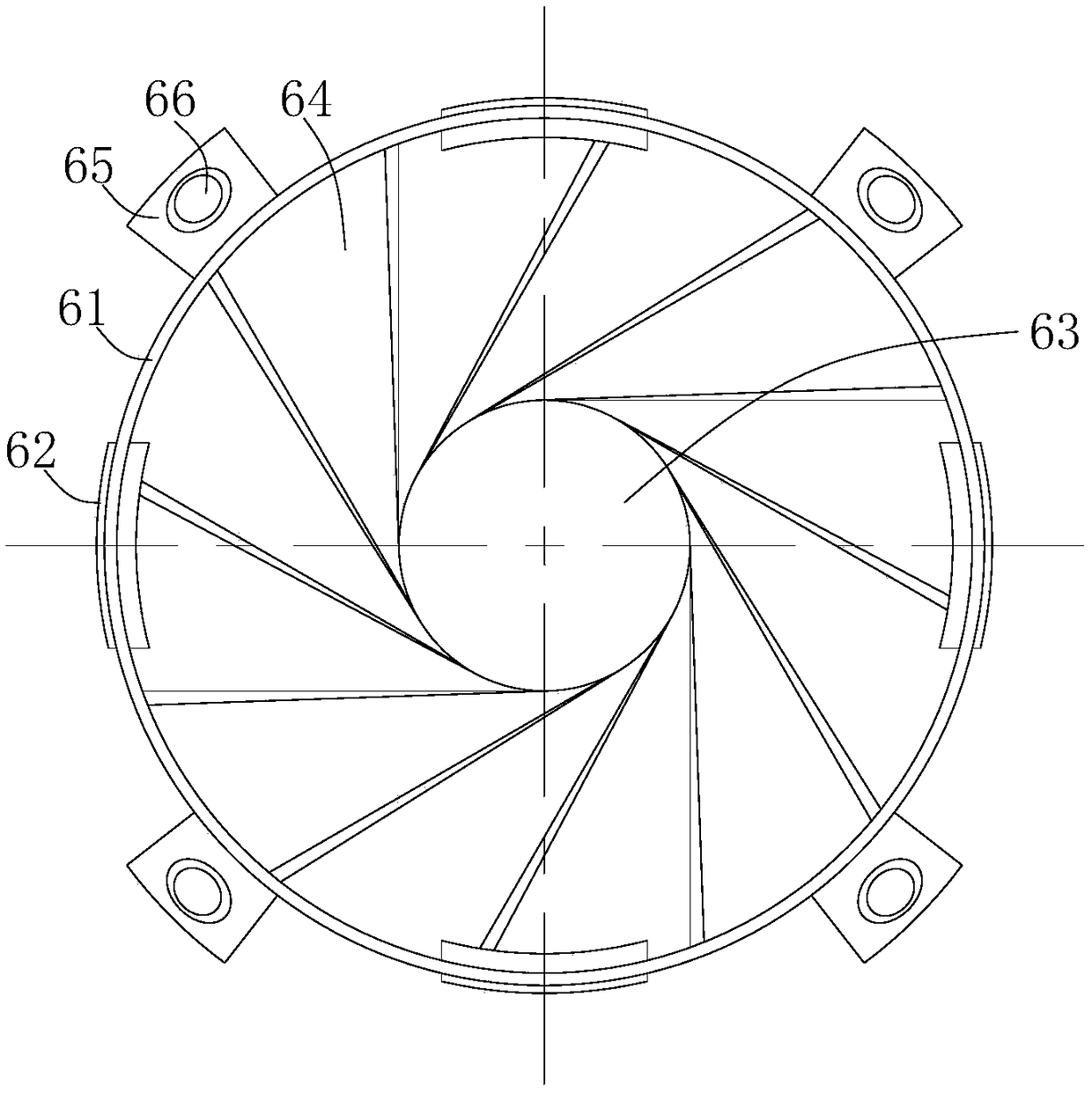

[0030] An air distributor 60 is installed on the side where the air inlet 11 is located in the housing 30 , and the air distributor 60 is fixed to the inner wall of the upper head through the connecting piece 13 .

[0031] An air collection cylinder 20 and a distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com