Method for improving slight saline-alkali land

A saline-alkali soil, mild technology, applied in chemical instruments and methods, fertilizers made from biological waste, applications, etc., can solve the problems of insufficient utilization of straw charcoal, low organic content of fertilizers, insufficient exchange volume, etc., to improve fertilizer conservation. Water retention capacity and permeability, improvement of soil structure, effect of increasing porosity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

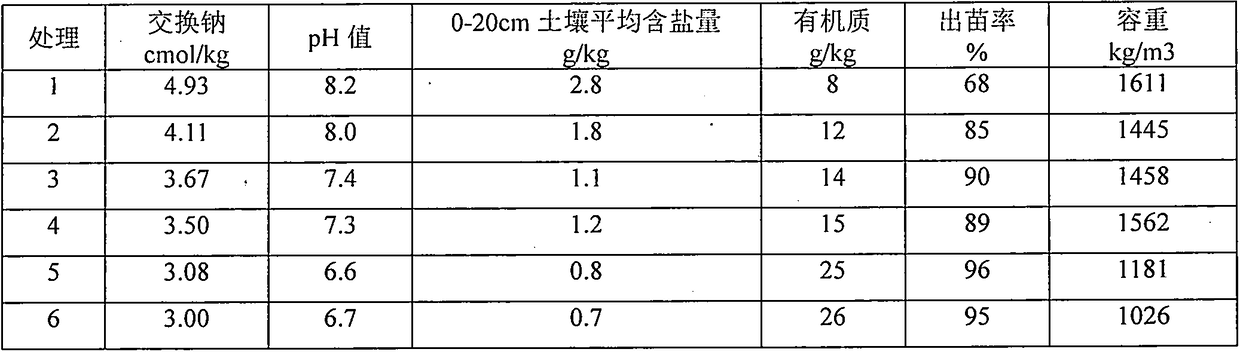

Embodiment 1

[0024] A special soil improver for mild saline-alkali land, characterized in that the improver consists of 40 parts of straw charcoal, 30 parts of cow dung, 20 parts of bone meal, 30 parts of vinegar residue, 20 parts of humic acid, 0.05 parts of probiotics, It is prepared from 15 parts of sodium polyacrylate, 20 parts of water-soluble potassium fertilizer, 20 parts of desulfurized gypsum, 0.01 part of trace elements, and an appropriate amount of water. The specific preparation includes the following steps:

[0025] a. Straw charcoal preparation: the straw is first carbonized at 220°C for 0.5h, then rapidly heated to 300°C for 1h, and then crushed into 2mm particles for later use;

[0026] b Mix 30 parts of cow dung, 20 parts of bone meal, 30 parts of vinegar residue, and 20 parts of humic acid, adjust the moisture content to 25%, add 0.05 parts of probiotics, ferment at 37°C for 26 hours, then cool down naturally and continue to ferment to room temperature, Dry until the wate...

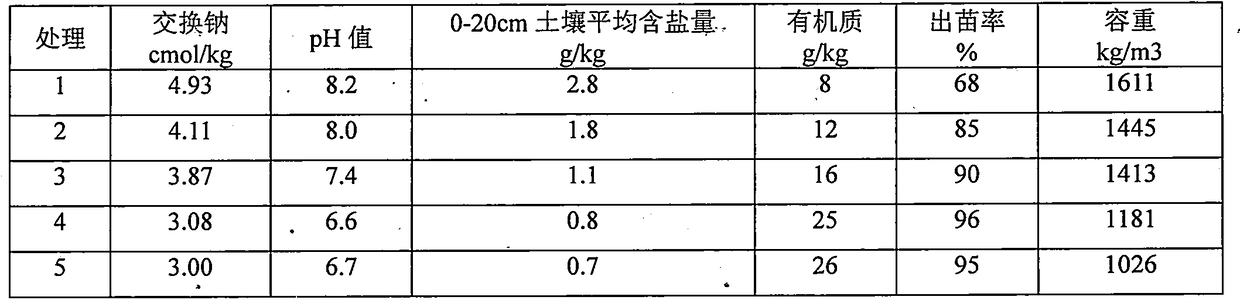

Embodiment 2

[0030] A special soil improver for mild saline-alkali land, characterized in that the improver consists of 50 parts of straw charcoal, 40 parts of cow dung, 23 parts of bone meal, 32 parts of vinegar residue, 23 parts of humic acid, 0.08 parts of probiotics, It is prepared from 18 parts of sodium polyacrylate, 23 parts of water-soluble potassium fertilizer, 23 parts of desulfurized gypsum, 0.2 parts of trace elements, and an appropriate amount of water. The specific preparation includes the following steps:

[0031] a. Straw charcoal preparation: the straw is first carbonized at 225°C for 0.8h, then rapidly heated to 308°C for 1.2h, and then crushed into 2.5mm particles for later use;

[0032] b Mix 40 parts of cow dung, 22 parts of bone meal, 33 parts of vinegar residue, and 22 parts of humic acid, adjust the moisture content to 28%, add 0.08 parts of probiotics, ferment at 42°C for 35 hours, then cool down naturally and continue to ferment to room temperature, Dry until the ...

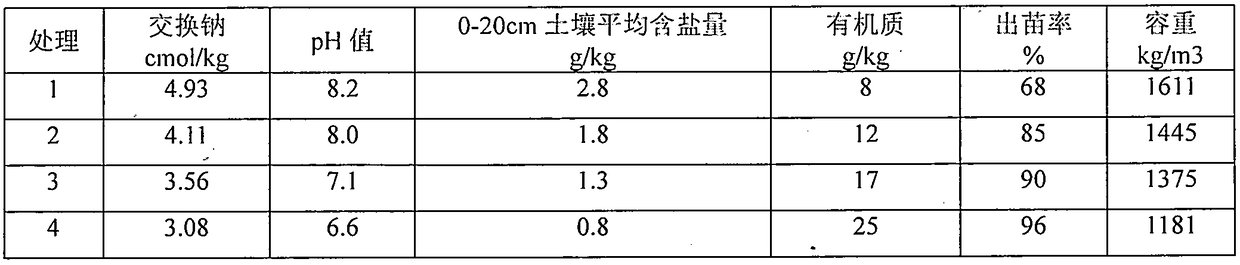

Embodiment 3

[0036] A special soil improver for mild saline-alkali land, characterized in that the improver consists of 60 parts of straw charcoal, 50 parts of cow dung, 25 parts of bone meal, 35 parts of vinegar residue, 25 parts of humic acid, 0.1 part of probiotics, It is prepared from 20 parts of sodium polyacrylate, 25 parts of water-soluble potassium fertilizer, 26 parts of desulfurized gypsum, 0.5 parts of trace elements, and an appropriate amount of water. The specific preparation includes the following steps:

[0037] a. Straw charcoal preparation: the straw is first carbonized at 230°C for 1 hour, then rapidly heated to 310°C for 1.5 hours, and then crushed into 3mm particles for later use;

[0038] b Mix 50 parts of cow dung, 25 parts of bone meal, 35 parts of vinegar residue, and 25 parts of humic acid, adjust the water content to 30%, add 0.1 part of probiotics, ferment at 45°C for 46 hours, then cool down naturally and continue to ferment to room temperature, Dry until the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com