A kind of mercury-free polyvinyl chloride production process

A polyvinyl chloride, production process technology, applied in catalysts, organic chemistry, hydrogenation hydrocarbon production, etc., can solve environmental pollution and other problems, and achieve the effect of solving mercury pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

[0044] The present invention will be further described below in combination with specific embodiments.

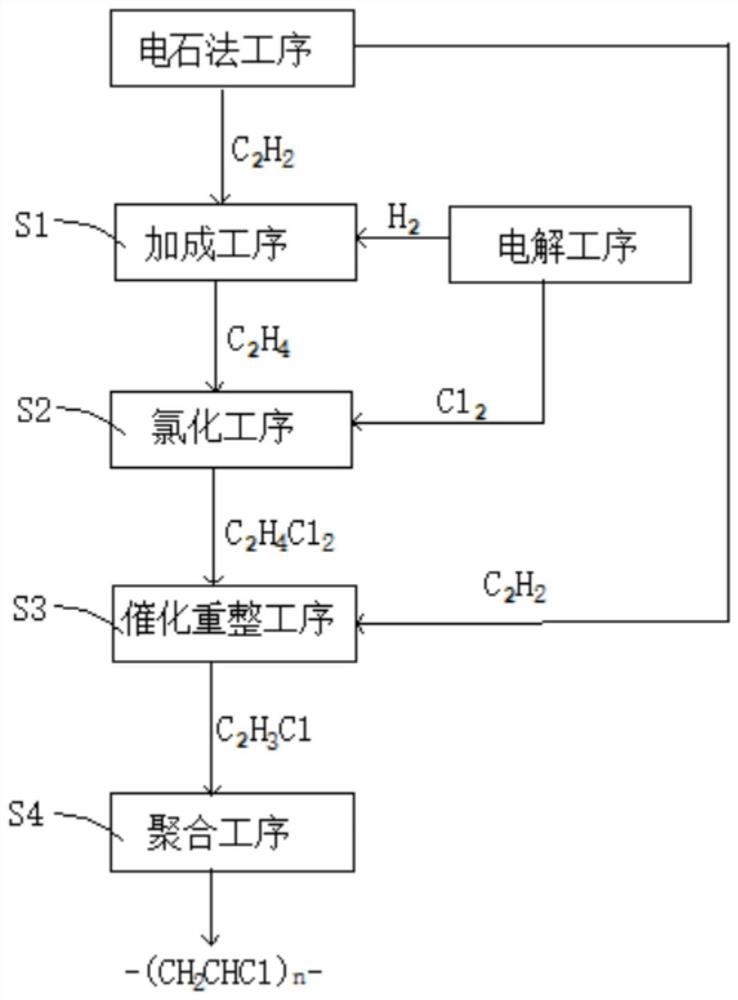

[0045] The invention provides a mercury-free polyvinyl chloride production process. Acetylene, hydrogen and chlorine are used as raw materials, and polyvinyl chloride is prepared through S1 addition process, S2 chlorination process, S3 catalytic reforming process and S4 polymerization process.

[0046] Above-mentioned raw material acetylene is made by calcium carbide process, and this calcium carbide process comprises:

[0047] A1 Preparation of crude acetylene gas: Calcium carbide enters the acetylene generator and dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com