Laser cladding device for inner walls of medium-diameter and small-diameter pipelines

A laser cladding, small diameter technology, applied in the field of laser cladding equipment, can solve problems such as space constraints, achieve good quality, reduce the size and weight of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

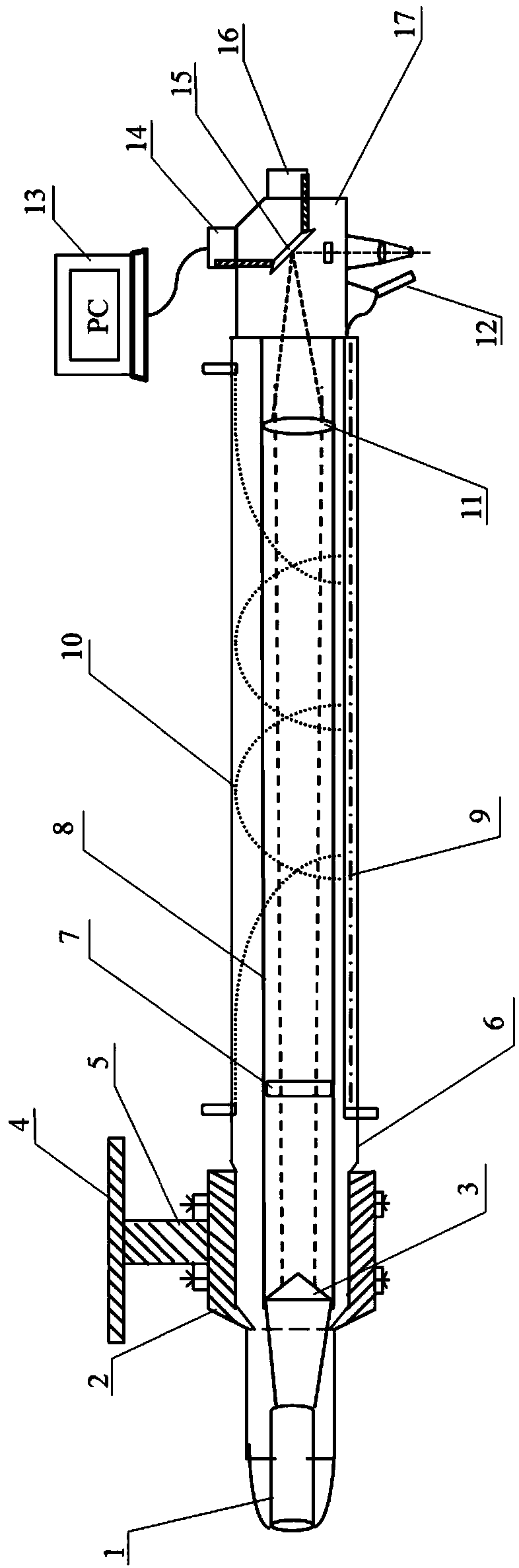

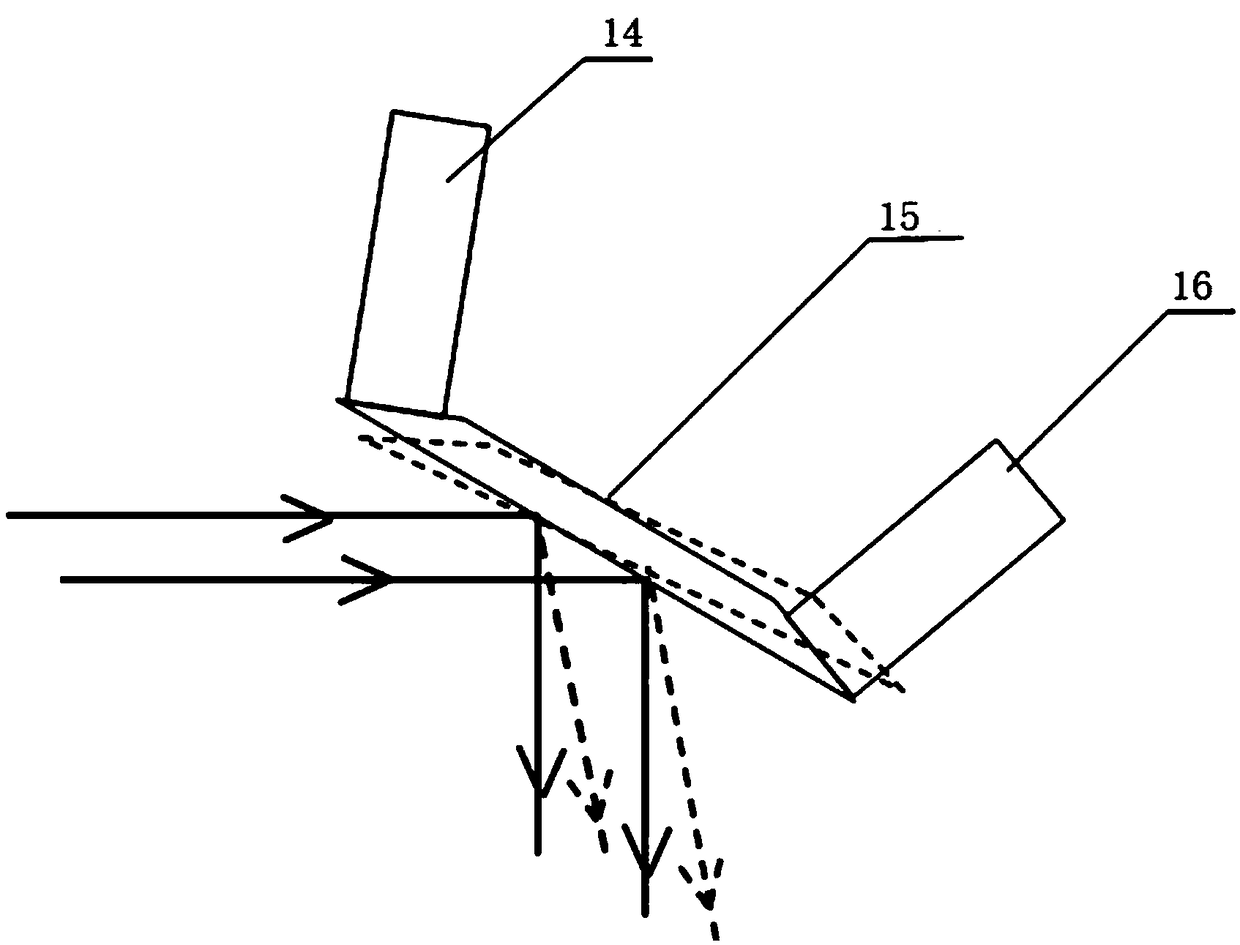

[0020] Use the present invention to the laser cladding device of domestic new-style SPCC cold-rolled carbon steel pipe inner wall diameter 200mm such as figure 1 As shown, it includes: an optical fiber connector 1, a cylinder body 6, a powder feeding nozzle 12, a cladding head 17, a fixing device and an adjusting device, wherein the fixing device includes a card seat 2, a connecting plate 5 and a connecting flange 4, and the cylinder body 6 includes Laser channel 8, powder feeding tube 9 and water-cooling tube 10, the laser channel 8 is provided with a collimating mirror 3, a protective mirror 7 and a focusing mirror 11 in sequence along the direction of laser advance, the optical fiber joint 1 is fixedly connected to the left end of the cylinder body 6, The card holder 2 is fixedly installed in the preset groove on the outer wall of the cylinder and fixed by bolts, the connecting plate 5 and the card holder 2 are fixedly connected by bolts, and the other end of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com