Laser top-surface cladding method

A top surface and laser technology, applied in metal material coating process, coating, etc., can solve the problems of no visibility, difficulty of top surface cladding, etc., to achieve no energy loss, avoid damage to the protective mirror, and strong usability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with the accompanying drawings and embodiments, the technical solution of the present invention is further introduced.

[0017] The anti-corrosion treatment process steps of a PTA exhaust pipe are as follows:

[0018] 1. Detect and record before cladding.

[0019] 2. Grind the cladding surface before cladding to clean up the corrosion layer.

[0020] 3. Laser cladding:

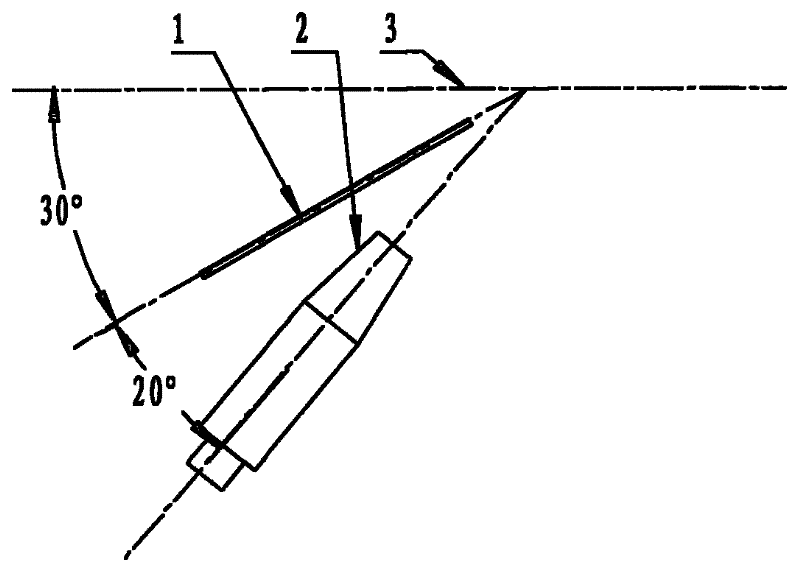

[0021] a) Before cladding, adjust the angle between the laser powder feeding head 1 and the laser processing head 2. As shown in the figure, when the laser top surface is cladding, the laser processing head 2 and the processed surface cannot be perpendicular to each other, and there must be a certain angle. Prevent the metal powder from entering the laser processing head 2. Metal powder entering the laser processing head 2 may cause damage to the protective mirror of the laser processing head 2. The laser processing head 2 and the top surface 3 are at 50°, and the clamp between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com