Degradable composite non-woven fabric material

A technology of non-woven fabrics and raw materials, applied in non-woven fabrics, textiles and papermaking, conjugated synthetic polymer man-made filaments, etc., can solve the problems of easy decomposition, limited use, and inability to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

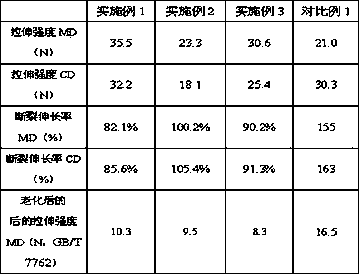

Embodiment 1

[0027] This embodiment provides a degradable composite non-woven fabric material, and its raw material formula includes the following components in parts by weight:

[0028] Polypropylene (polypropylene resin, T022) 50 parts;

[0029] Polylactic acid resin (REVODE201) 60 parts;

[0030] Polycarbonate resin (GE Company 123R-111) 30 parts;

[0031] Maleic anhydride grafted polystyrene (PS-35) 20 parts;

[0032] Flame retardant (magnesium hydroxide) 40 parts;

[0033] Color masterbatch (Haoze) 5 copies;

[0034] Lubricant (polyethylene wax) 5 parts;

[0035] The method for preparing the antibacterial non-woven fabric includes the following steps:

[0036] (A) Add the formulated amount of polypropylene, polylactic acid resin, polycarbonate resin and maleic anhydride grafted polystyrene into the mixer, and mix at 100~120°C and 500~600 revolutions per minute. First mixture

[0037] (B) Introduce the first mixture into the extruder, add the formulated amount of flame retardant, color masterbatch a...

Embodiment 2

[0041] This embodiment provides a degradable composite non-woven fabric material, which is basically the same as the preparation method in Example 1, except that its raw material formula includes the following components by weight:

[0042] 70 parts of polypropylene (polypropylene resin, T022);

[0043] Polylactic acid resin (REVODE201) 50 parts

[0044] Polycarbonate resin (GE company 123R-111) 5 parts;

[0045] Maleic anhydride grafted polystyrene (PS-35) 5 parts;

[0046] 30 parts of flame retardant (magnesium hydroxide);

[0047] Color masterbatch (Haoze) 0.5 copies;

[0048] Lubricant (polyethylene wax) 2 parts;

Embodiment 3

[0050] This embodiment provides a degradable composite non-woven fabric material, which is basically the same as the preparation method in Example 1, except that its raw material formula includes the following components by weight:

[0051] 80 parts of polypropylene (polypropylene resin, T022);

[0052] 55 parts of polylactic acid resin (REVODE201)

[0053] 15 parts of polycarbonate resin (GE Company 123R-111);

[0054] 15 parts of maleic anhydride grafted polystyrene (PS-35);

[0055] Flame retardant (magnesium hydroxide) 35 parts;

[0056] Color masterbatch (Haoze) 5 copies;

[0057] Lubricant (polyethylene wax) 3 parts;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com