Waterproof paper pulp molding material with high compressive strength and preparation method thereof

A technology of pulp molding and compressive strength, applied in papermaking, paper, reinforcing agent addition, etc., can solve the problems of whiteness effect of finished products, limited binding force, increased cost, etc., to improve retention and drainage, The effect of improving compressive performance and enhancing compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

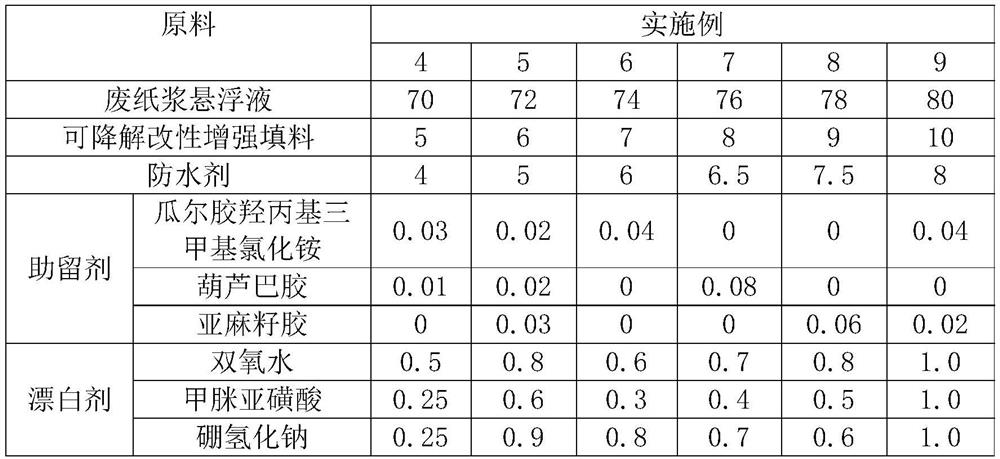

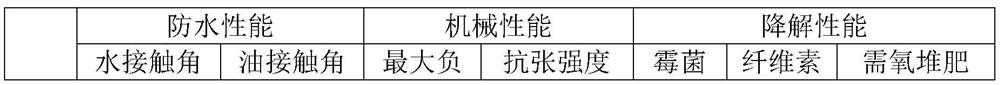

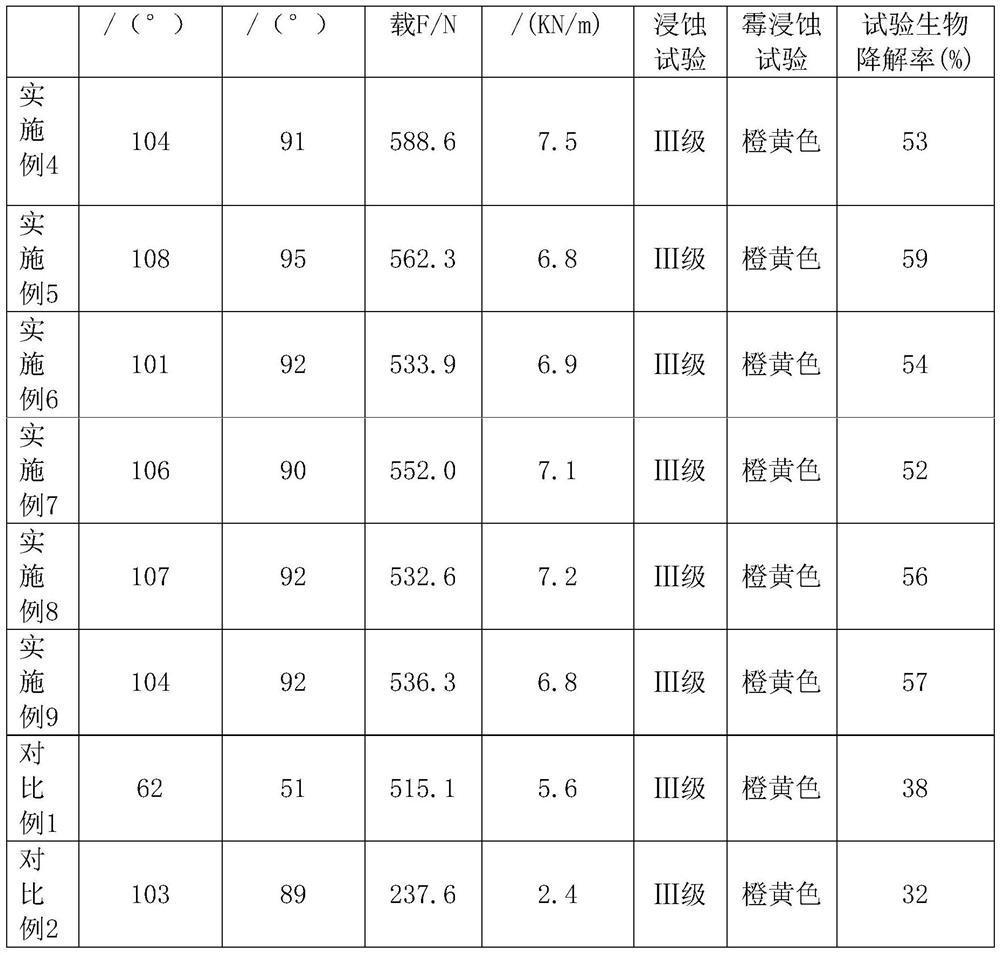

Examples

Embodiment 1

[0035] This embodiment provides a preparation method of a degradable water repellent, and the preparation steps include:

[0036] S1. Preparation of glyceryl polypropylene oxide polyether polyol

[0037] Put the initiator (sucrose, glycerin) and catalyst (the molar ratio of sucrose and glycerin is 1:0.95~1, and the catalyst is 1%~1.5% of the mass of the initiator) into the polymerization tank, and replace the air with nitrogen for 3~5 After three times, heat to 110-120°C, vacuumize while stirring, let the sucrose, glycerin and catalyst react completely, and the reaction time is 1-1.2h. Use a high-pressure pump to add propylene oxide, and control the dripping rate of propylene oxide to 3-6L / min to maintain the polymerization pressure at 0.3-0.5MPa and the polymerization temperature at 110-120°C. After adding propylene oxide, keep the temperature constant , continue to react in the reactor until the pressure is negative pressure, stop the reaction. Transfer the product obtaine...

Embodiment 2

[0043] This example provides a method for preparing a degradable modified reinforcing filler. The preparation steps include:

[0044] S1. Nano CaCO 3 modified

[0045] Weigh 5kg nano-CaCO 3 Put it into a reaction kettle, add 50L of distilled water, stir in a constant temperature water bath and heat to 80°C. Add 85L of water into the reaction kettle, and configure the modifier according to the stearic acid: sodium laurate mass ratio of 1:1, and slowly add it into the above reaction kettle after fully dissolving, and heat to 90°C, and stir for 1 hour to obtain Nano-CaCO 3 modified suspension.

[0046] S2. Chitosan-coated modified nano-CaCO 3

[0047] nanoCaCO 3 Modified suspension, cooled to 70°C, added CaCO 3 Adipic acid solution with a mass of 100-120%, stirred for 1 hour, filtered, washed to remove unreacted adipic acid, redispersed in distilled water, added dropwise to chitosan solution with a concentration of 5%, reacted, filtered, fully washed , dried, and ground ...

Embodiment 3

[0049] This embodiment provides a method for preparing a high compressive strength, waterproof pulp molding material, and the preparation steps include:

[0050] S1. Cut waste corrugated paper, waste coated paper, and straw with a shredder, mix them according to the mass ratio of waste corrugated paper, waste coated paper, and straw at a ratio of 1:0.3:1.8, soak, beat, and filter to obtain filter residue, which is washed with water for 3 to 5 After the second time, it is added into water to make a waste paper pulp suspension with a solid content of 13%.

[0051] S2. Pump the waste paper pulp suspension to the 2 o 2 The first bleaching treatment tank, after stirring for 30 minutes, pumped to the second bleaching treatment tank containing formamidine sulfinic acid, steam 90 ° C, kept stirring for 30 minutes, then pumped to the third bleaching treatment tank containing sodium borohydride, steam 60 ℃, keep stirring for 60min.

[0052] S3. Pump the bleached waste paper pulp susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com