Degradable functional wet tissue and preparation method thereof

A functional wet wipe technology, which is applied in the field of daily necessities, can solve the problems of reduced wet wipe performance, lack of mechanical strength and antibacterial properties, and achieve good toughness, good antibacterial effect, good solvent resistance and migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

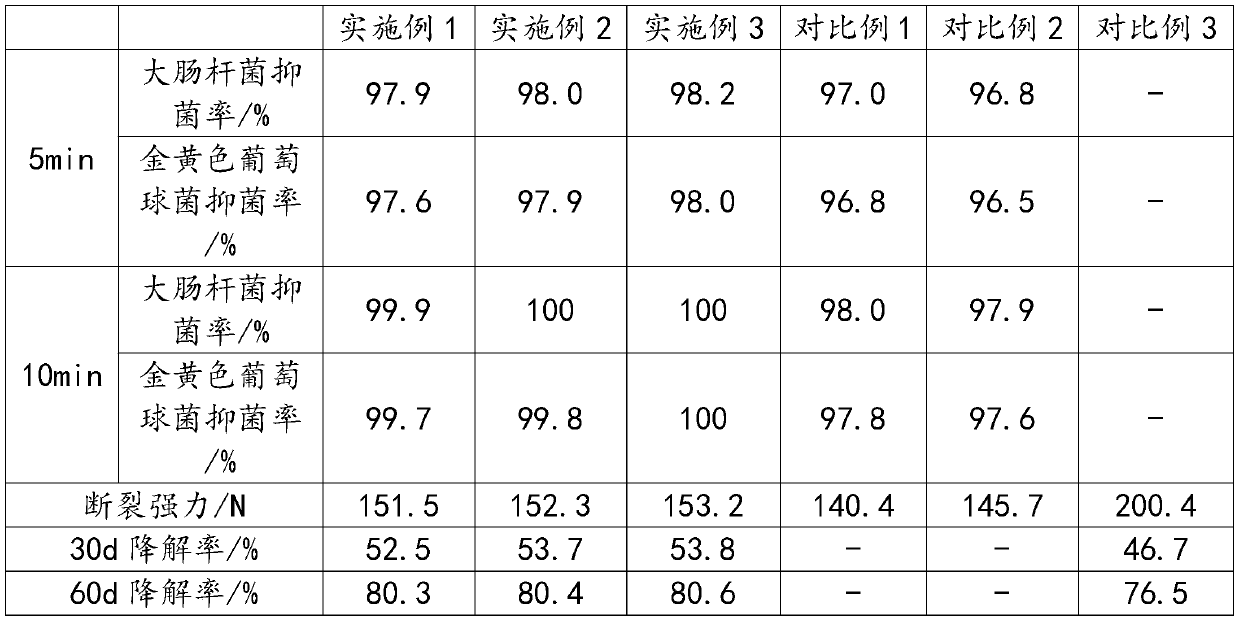

Examples

preparation example Construction

[0044] The preparation method of this wet wipe is as follows:

[0045] Submerge the base material of the wet tissue completely in the wetting liquid, raise the temperature, soak it at 60-65° C. for 80-90 min, let it cool down to room temperature, and then take it out to obtain a wet tissue.

Embodiment 1

[0047] A degradable functional wet tissue, including a wet tissue base material and a soaking liquid, the wet tissue base material is made of modified polyester fiber, bamboo pulp fiber and cotton fiber, the modified polyester fiber, bamboo pulp fiber The fiber and cotton fiber are mixed according to the mass ratio of 1.5:1:2, and then opened, removed impurities, and formed into a web on the combined blowing and carding equipment. 2 The nonwoven fabric obtains the wet wipe base material;

[0048] The wetting liquid is made of the following raw materials in parts by weight: 3 parts of modified chitosan, 0.8 parts of rosemary essential oil, 1 part of peppermint essential oil, 2 parts of polyglycerol ester, and 70 parts of purified water;

[0049] Add rosemary essential oil, peppermint essential oil and polyglycerol ester together into purified water, stir for 25 minutes, then add modified chitosan, and continue stirring for 30 minutes to obtain a wetting liquid;

[0050] This w...

Embodiment 2

[0053] A degradable functional wet tissue, including a wet tissue base material and a soaking liquid, the wet tissue base material is made of modified polyester fiber, bamboo pulp fiber and cotton fiber, the modified polyester fiber, bamboo pulp fiber The fiber and cotton fiber are mixed according to the mass ratio of 1.5:1:2, and then opened, removed impurities, and formed into a web on the combined blowing and carding equipment. 2 The nonwoven fabric obtains the wet wipe base material;

[0054] The wetting liquid is made of the following raw materials in parts by weight: 3.5 parts of modified chitosan, 0.9 parts of rosemary essential oil, 1.1 parts of peppermint essential oil, 2.5 parts of polyglycerol ester, and 75 parts of purified water;

[0055] Add rosemary essential oil, peppermint essential oil and polyglycerol ester into purified water, stir for 25-30 minutes, then add modified chitosan, and continue stirring for 30-40 minutes to obtain a wetting liquid;

[0056] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com