Environment-friendly heat shrinkable film

A heat-shrinkable film, environmentally friendly technology, applied in the field of packaging film, can solve problems such as poor shrinkage, and achieve the effects of improving shrinkage, good shrinkage, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

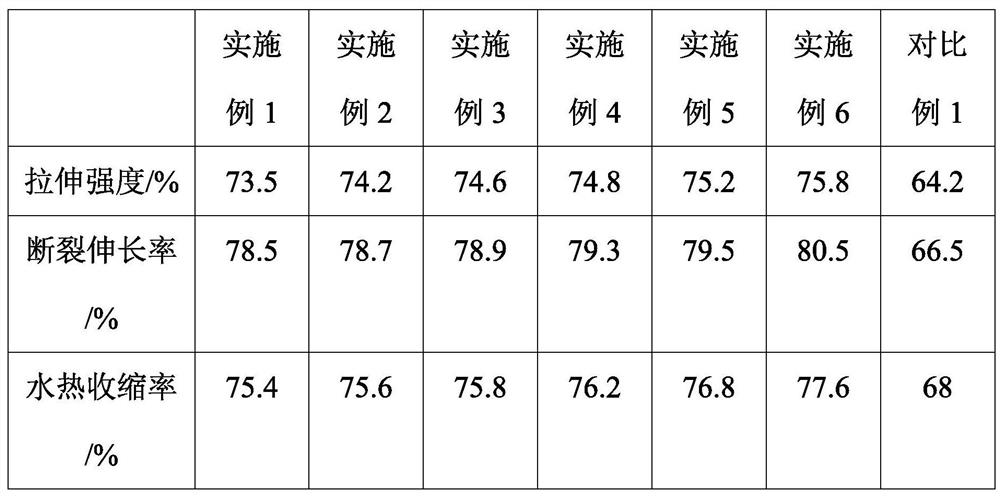

Examples

Embodiment 1

[0023] An environmentally friendly heat shrinkable film, comprising the following raw materials in parts by mass: 50 parts of polyester, 0.5 parts of edible hydrophobic substance, 0.5 parts of emulsifier, 1.5 parts of antioxidant, 1.2 parts of light stabilizer, and 1 part of modified collagen.

[0024] Polyester is composed of lactic acid-co-glycolic acid, polylactic acid and polycaprolactone, wherein the mass ratio of lactic acid-co-glycolic acid, polylactic acid and polycaprolactone is 7:2:1, and the edible hydrophobic substance is Stearic acid, emulsifiers are sucrose fatty acid esters and polyglycerol fatty acid esters.

[0025] In this embodiment, a method for preparing an environmentally friendly heat shrinkable film comprises the following steps:

[0026] (1) Mix the collagen with polyethylene glycol first, stir and react in an oil bath, the reaction temperature is 75°C, and the reaction time is 2 hours. After the reaction is completed, add oxalic acid dropwise, and the...

Embodiment 2

[0030] An environmentally friendly heat shrinkable film, comprising the following raw materials in parts by mass: 60 parts of polyester, 0.6 parts of edible hydrophobic substance, 0.6 parts of emulsifier, 1.6 parts of antioxidant, 1.3 parts of light stabilizer, and 2 parts of modified collagen.

[0031] Polyester is composed of lactic acid-co-glycolic acid, polylactic acid and polycaprolactone, wherein the mass ratio of lactic acid-co-glycolic acid, polylactic acid and polycaprolactone is 7:2:1, and the edible hydrophobic substance is Stearic acid, emulsifiers are sucrose fatty acid esters and polyglycerol fatty acid esters.

[0032] In this embodiment, a method for preparing an environmentally friendly heat shrinkable film comprises the following steps:

[0033] (1) Mix the collagen with polyethylene glycol first, stir and react in an oil bath, the reaction temperature is 75°C, and the reaction time is 2 hours. After the reaction is completed, add oxalic acid dropwise, and th...

Embodiment 3

[0037] An environmentally friendly heat shrinkable film, comprising the following raw materials in parts by mass: 70 parts of polyester, 0.7 parts of edible hydrophobic substance, 0.7 parts of emulsifier, 1.7 parts of antioxidant, 1.4 parts of light stabilizer, and 3 parts of modified collagen.

[0038] Polyester is composed of lactic acid-co-glycolic acid, polylactic acid and polycaprolactone, wherein the mass ratio of lactic acid-co-glycolic acid, polylactic acid and polycaprolactone is 7:2:1, and the edible hydrophobic substance is Stearic acid, emulsifiers are sucrose fatty acid esters and polyglycerol fatty acid esters.

[0039] In this embodiment, a method for preparing an environmentally friendly heat shrinkable film comprises the following steps:

[0040] (1) Mix the collagen with polyethylene glycol first, stir and react in an oil bath, the reaction temperature is 75°C, and the reaction time is 2 hours. After the reaction is completed, add oxalic acid dropwise, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com