Bridge asphalt pavement structure and construction method

An asphalt pavement and construction method technology, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of easily mixed fillers, fast decay of anti-skid performance, adverse effects of expansion joints, etc., and achieves the reduction of construction noise and dust pollution, The construction time is shortened and the drainage effect is favorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

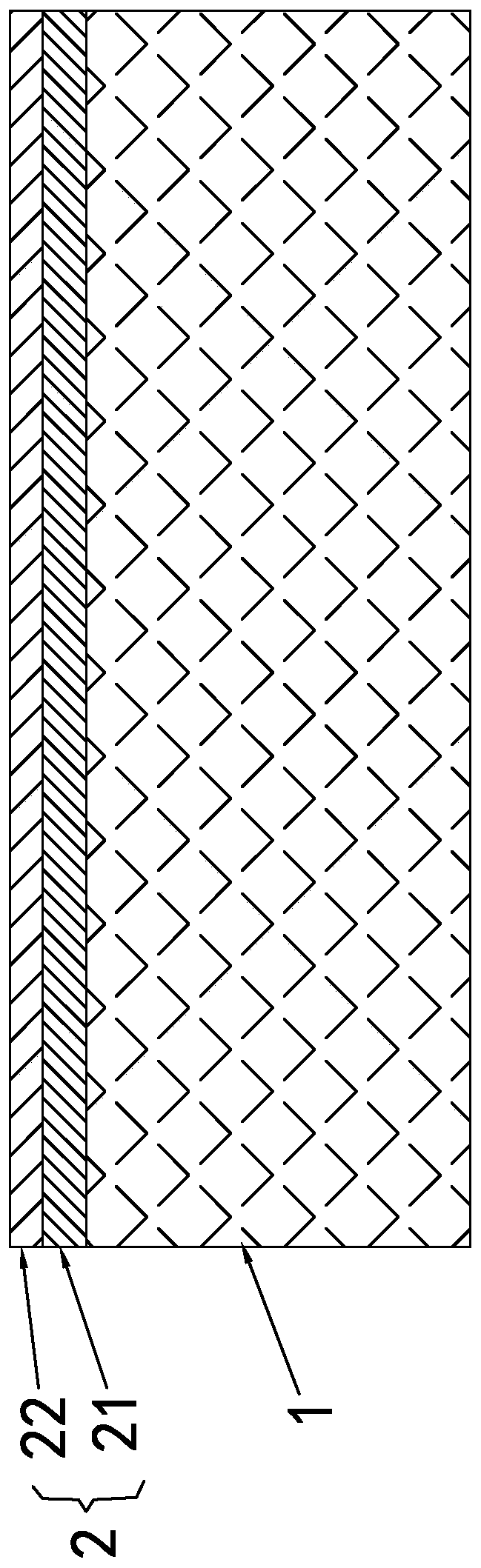

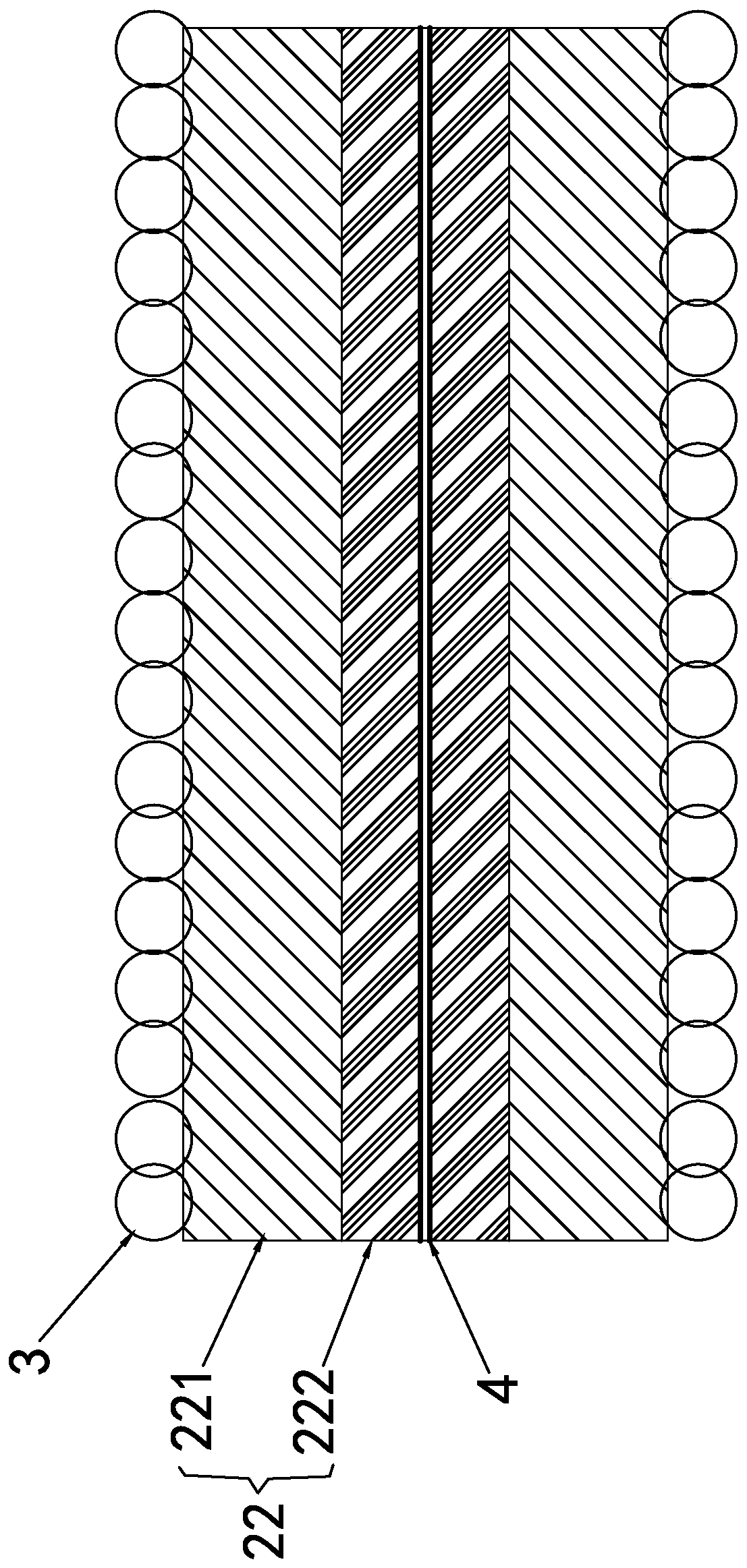

[0022] In terms of the drainage path inside the structure, it can be divided into two types according to the situation: when it rains, the pavement is drained vertically; when it is sunny, it is drained through evaporation. Side stones 3 are arranged on the left and right side edges of the road paved with asphalt for supporting, and the top surface of the side stones 3 will be higher than the elevation of the road surface, so the side stones 3 block the lateral drainage of moisture inside the road surface. by figure 2 If the direction in is used as the reference, the longitudinal direction of the road surface refers to the left and right directions, that is, the extending direction of the road surface; the horizontal direction of the road surface refers to the up and down direction, that is, the width direction of the road surface. During the rainy period, the water retained by the pavement structure has two flow directions, vertical and horizontal. When the water flows in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com