High-altitude cantilever construction platform support system and construction method thereof

A technology of construction platform and support system, which is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc. The effect of reducing investment and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

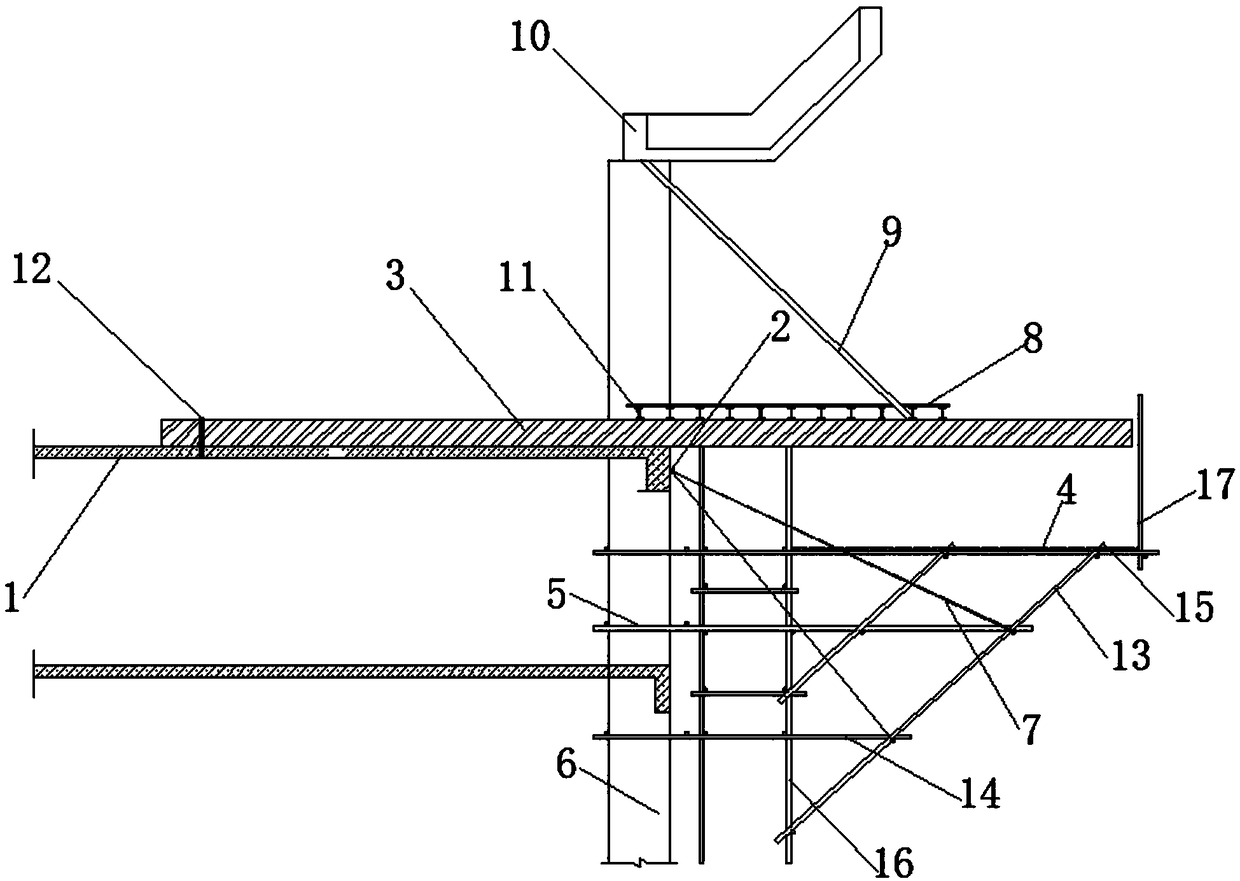

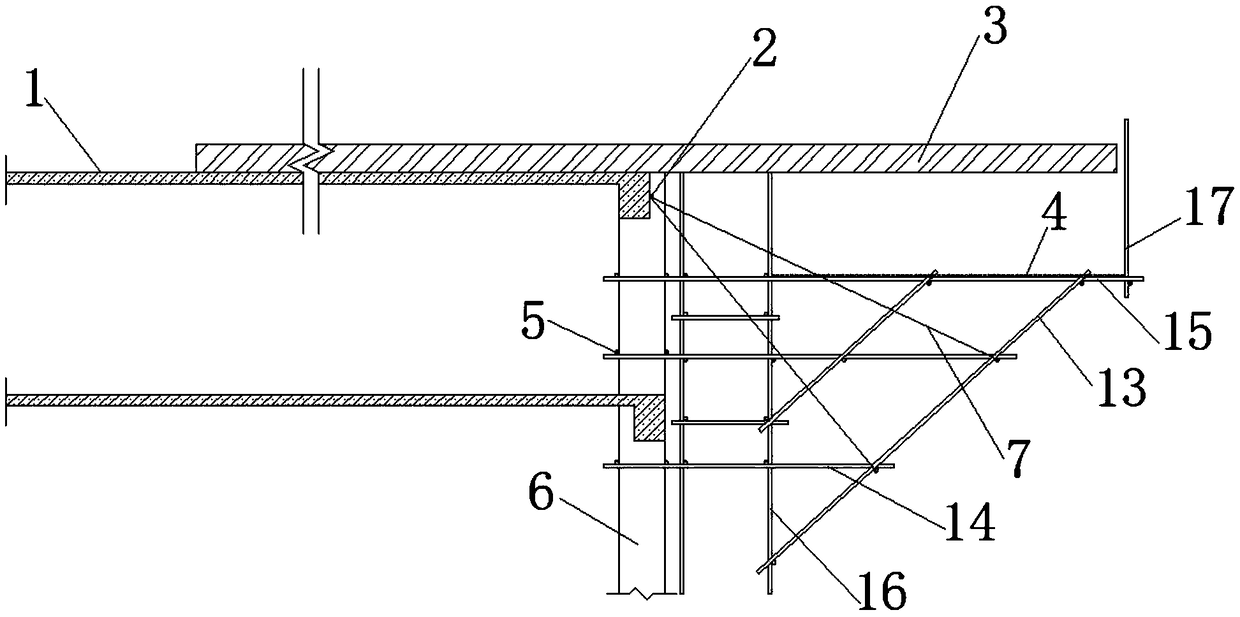

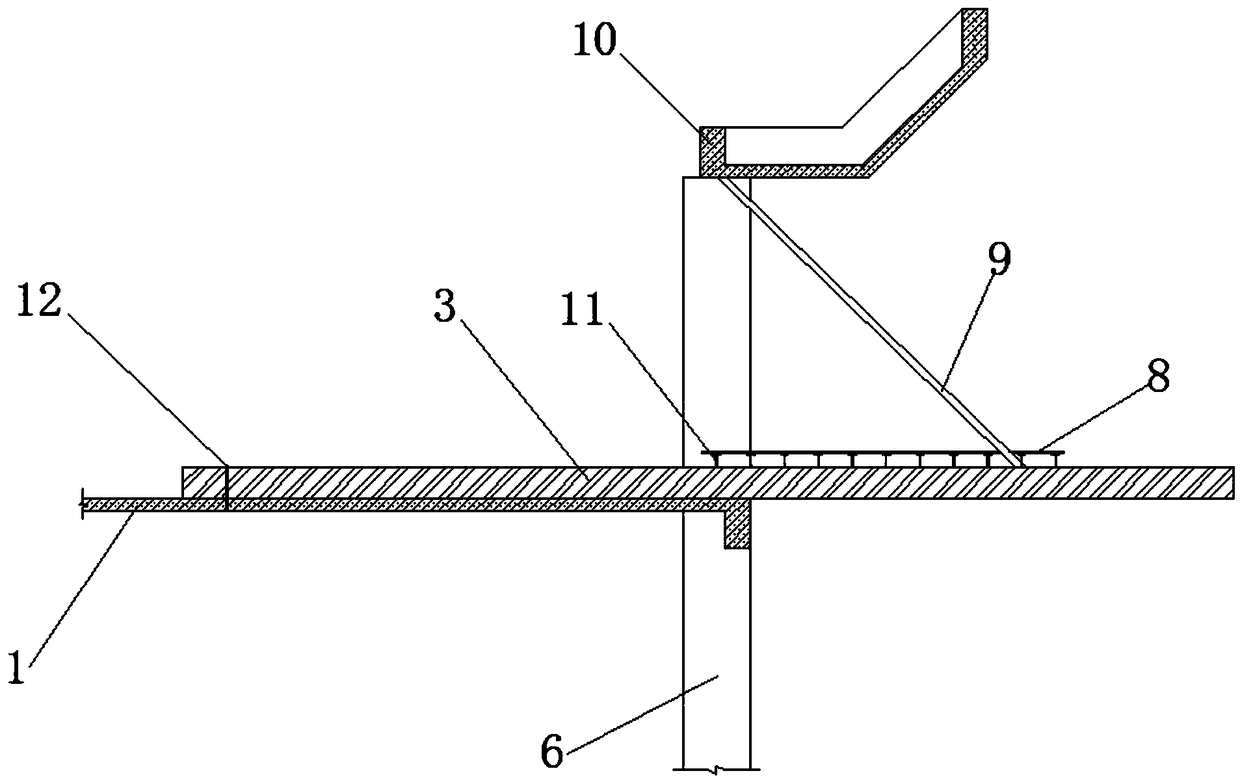

[0045] like Figure 1 to Figure 3 The support system of a high-altitude cantilevered construction platform is set under the support system of the formwork and scaffolding of the upper cantilevered concrete member, including the floor slab 1, the concrete structural column 6, the structural edge beam 10 and the scaffolding of the outer wall 16, including the cantilevered safety An operation platform and a cable-stayed force-bearing support system, the cantilevered safety operation platform is located below the cable-stayed force-bearing support system,

[0046] The cantilever safety operation platform includes the following structures:

[0047]The floor 1 located on the upper floor of the cantilever safety operation platform is provided with a wire rope suspension ring 2, and the concrete structure column 6 is provided with 3 layers of steel pipe hoops 5, and the steel pipe hoops 5 are provided with cross bars. The cross bar includes a platform cross bar 15 and a supporting cr...

Embodiment 2

[0067] The rest are the same as in Embodiment 1, the difference being that the setting interval of the main stressed beam 3 is a horizontal distance of 2m; A 12m-long 36a I-beam cantilevered over 2m is used as the main force beam 3 of the cable-stayed support system.

Embodiment 3

[0069] The rest are the same as in Embodiment 1, the difference being that the setting interval of the main stressed beam 3 is a horizontal distance of 3m; A 12m-long 36a I-beam cantilevered by 3m is used as the main force beam 3 of the cable-stayed support system.

[0070] Through practice, the present invention can effectively avoid the mutual influence with the construction of the external wall, effectively reduce the construction period, save more than 75% of the erection cost compared with the floor-to-ceiling scaffolding, has high technical content, is environmentally friendly, energy-saving and material-saving, and has broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com