Cartridge case substrate swelling assembling method

An assembly method and expansion pressure technology, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of easy failure of sealing, high scrap rate, damaged parts, etc., and achieve low labor intensity, uniform expansion, and large axial tension. The effect of de-strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

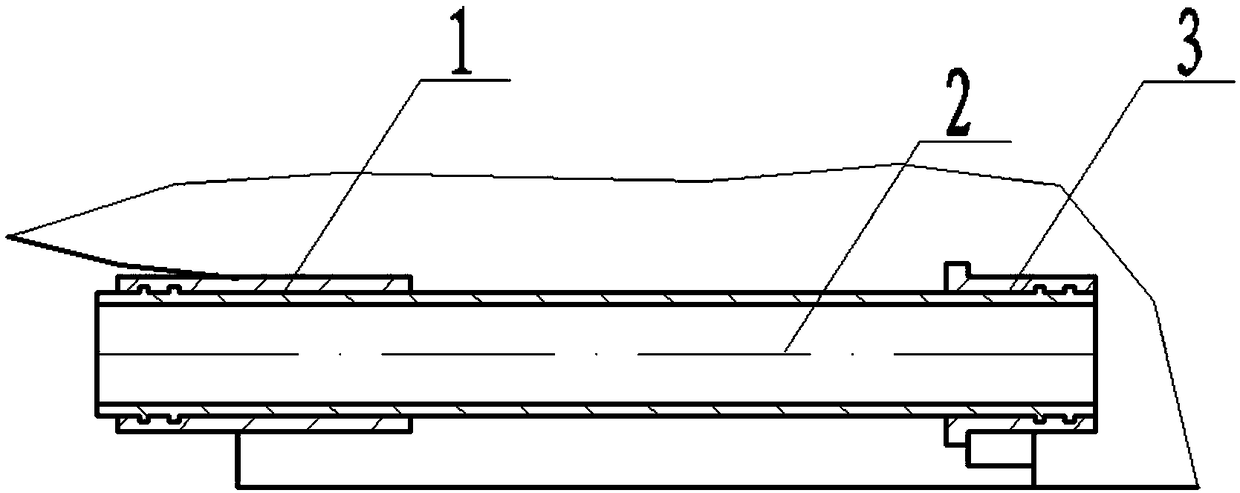

Image

Examples

Embodiment

[0022] A kind of expansion and pressure assembly method of cartridge base body of the present invention, the concrete steps of this method are as follows:

[0023] 1. Process the inner and outer diameters of both ends of the threading pipe to ensure uniform wall thickness, wall thickness difference ≤ 0.05mm, roughness Ra ≤ 6.3μm,

[0024] 2. The difference between the radial depth of the slot and the outer diameter of the threading pipe is 1-2mm, and the coaxiality relative to the center line of the front and rear sleeves is ≤0.02mm.

[0025] 3. The inner diameter of the front and rear sleeves and the outer diameter of the threading pipe adopt clearance fit, and the size is within 0.05mm.

[0026] 4. The inner diameter roughness of the front and rear sleeves is Ra≤6.3μm, and the roughness of the groove at the expansion joint is Ra≤12.5μm.

[0027] 5. Use strength expansion to ensure the sealing performance of the connection between the threading pipe and the front and rear sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com