Direct air cooling temperature field on-line monitoring device and method

A monitoring device and temperature field technology, applied in measurement devices, thermometers, thermometer parts, etc., can solve the problems of freezing damaged tube bundles, poor real-time performance, and long time required, so as to reduce back pressure, avoid regional leakage, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

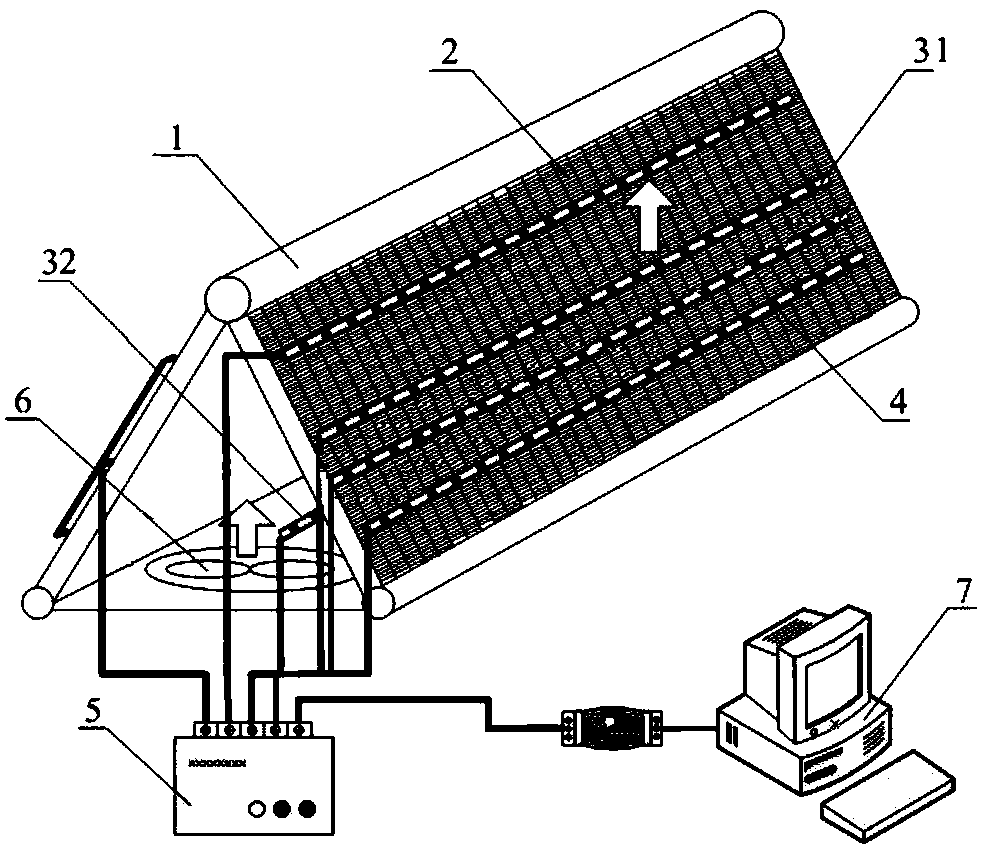

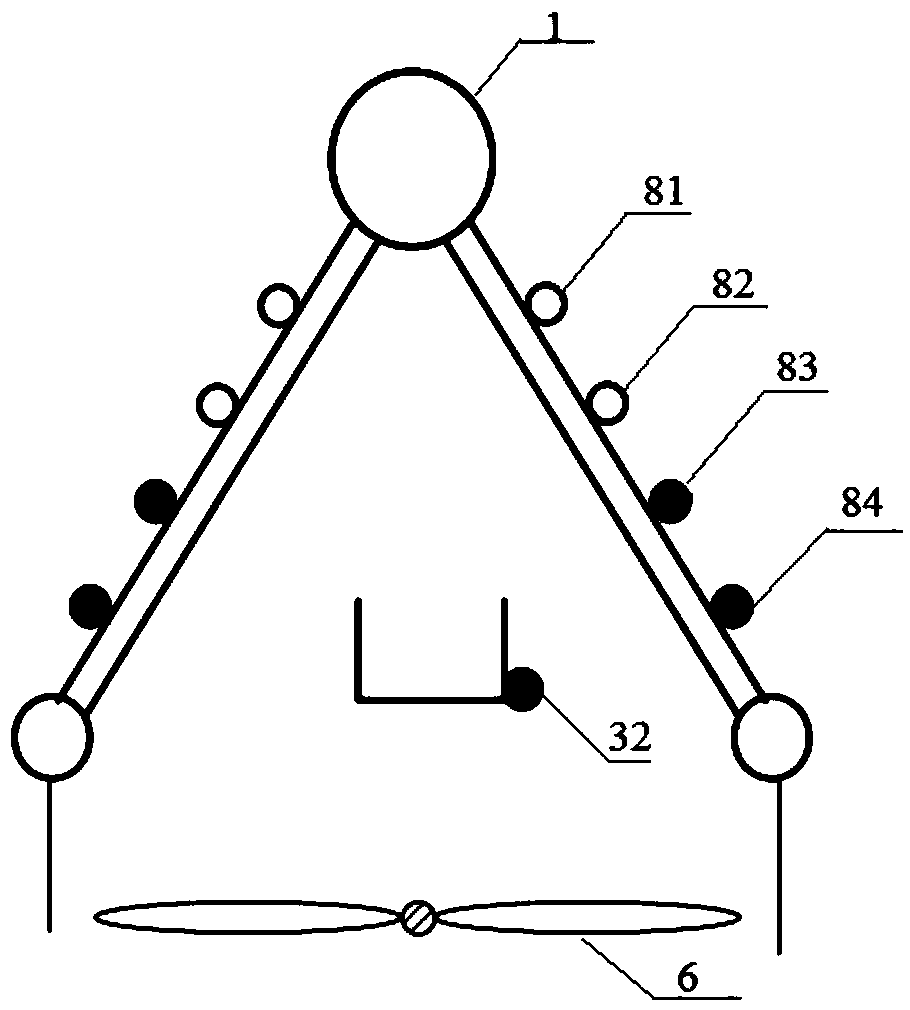

[0037] Example 1, such as figure 1 As shown, a direct air-cooled temperature field online monitoring device described in the embodiment of the present invention includes: several temperature measuring cables A 31, temperature measuring cables B 32, and several temperature measuring cables A 31 and temperature measuring cables B 32. A plurality of temperature measuring sensors 4, a collector 5 and a monitoring host 7.

[0038] Several temperature measuring cables A 31 are arranged at certain intervals on the outer surface of the air condenser, and are located on the outer surface of the direct system radiator tube bundle 2 connected to the direct air cooling system steam distribution pipe 1 . The temperature measurement cable B 32 is arranged at the outlet of the fan 6 of the direct air cooling system inside the air condenser. Several temperature measuring sensors 4 are arranged at certain intervals on several temperature measuring cables A 31 , and several temperature measuri...

Embodiment 2

[0049] Embodiment 2, a direct air-cooling temperature field online monitoring method according to the embodiment of the present invention, includes the following steps:

[0050] Step 1, arrange several temperature measuring cables A 31 at certain intervals on the outer surface of the air condenser, and arrange several temperature measuring sensors 4 at certain intervals on each temperature measuring cable A 31 .

[0051] Step 2, arrange a temperature measurement cable B32 at the outlet of the fan 6 of the direct air cooling system of the air condenser, and arrange a number of temperature measurement sensors 4 at certain intervals on the temperature measurement cable B32.

[0052] Step 3, connect several temperature measuring cables A 31 and B 32 to the collector 5 , and connect the collector 5 to the monitoring host 7 .

[0053] Step 4: The temperature sensors 4 on several temperature measuring cables A 31 and B 32 respectively detect the temperatures of the corresponding temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com