Detection and laser restoration module group

A laser repair and module technology, applied in laser welding equipment, measuring devices, optical testing flaws/defects, etc., can solve problems such as inability to detect and repair, waste of resources, increase product production costs, etc., to achieve high detection and repair efficiency, The effect is good and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

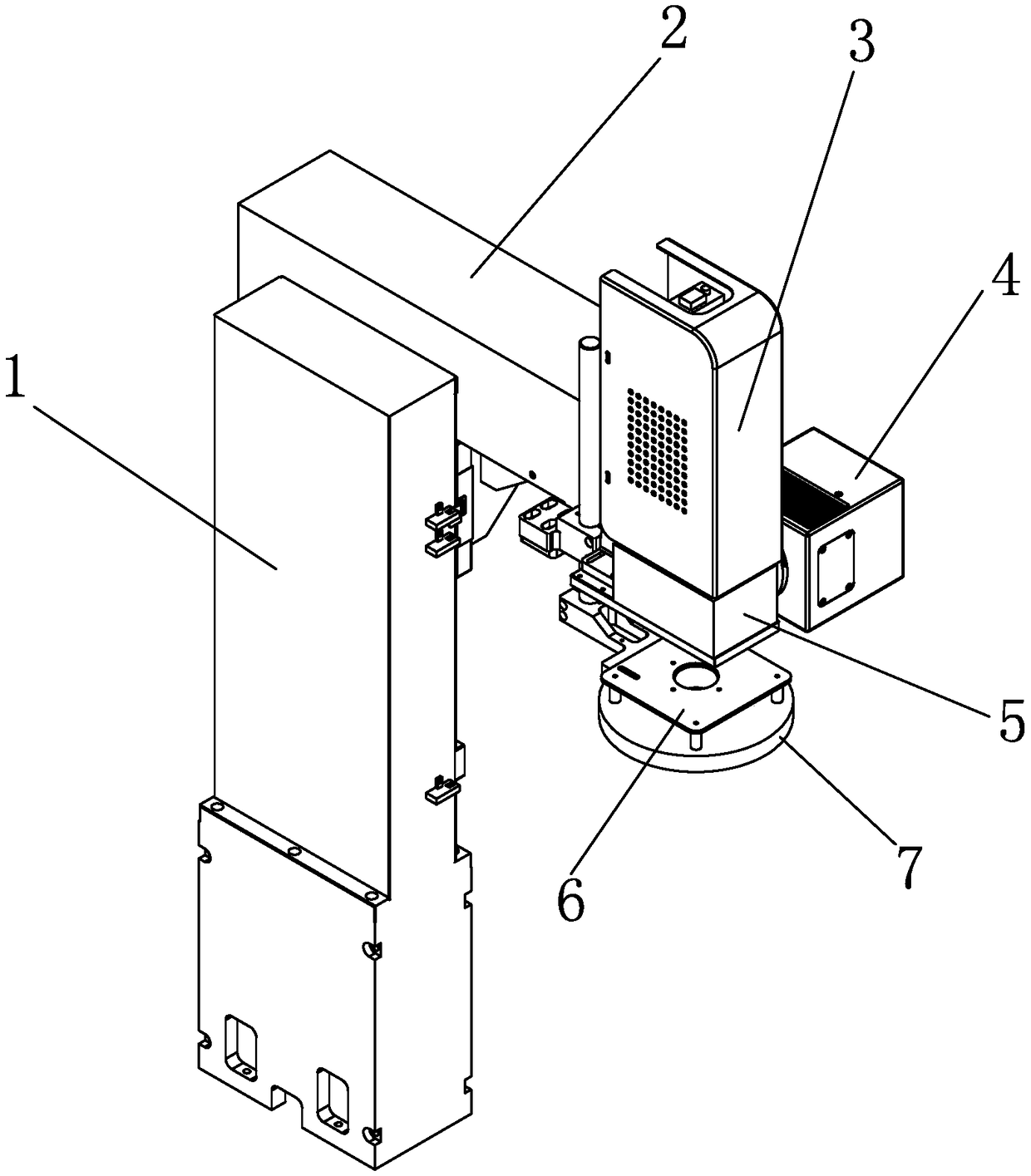

[0020] combine figure 1 , The invention discloses a detection and laser repair module, which is used for repairing white spots and different colors on the surface of an electronic product shell or panel after anodic oxidation. The present invention includes a frame 1, a laser marking machine 2, and a vision module. The frame 1 is arranged vertically, and the laser marking machine 2 is installed on the frame 1. A vision module is installed on the front of the laser marking machine 2. In order to better control the height of the laser marking machine 2 and the vision module in the vertical direction, the frame 1 is provided with linear guide rails along the vertical direction. A driving component and a mounting slider are arranged on the linear guide rail. The laser marking machine 2 is movably installed on the linear guide rail by installing a slider; the driving part drives the laser marking machine 2 to move along the linear guide rail. Specifically, the driving part incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com