Method for evaluating uncertainty of measurement results of battery combustion testing machine

A technology of combustion test and measurement results, which is used in chemical analysis, electrical digital data processing, special data processing applications using combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] Experimental object: No. 1 battery combustion test machine

[0136] 1. Evaluation of measurement uncertainty of burner inner diameter

[0137] The standard uncertainty component u introduced by the repeatability of the measurement 11 :

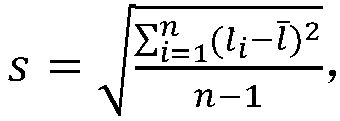

[0138] Perform 10 repeated measurements with equal precision on the 9.5mm piston diameter, and get the standard deviation u of a single experiment 11 =s≈0.016;

[0139] Uncertainty component u introduced by caliper indication error 12 :

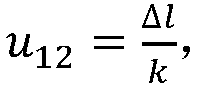

[0140] For a digital caliper with a measuring range of 300mm and a division value of 0.01mm, the indication error is ±0.04mm, which is evenly distributed, and the inclusion factor is So its standard uncertainty

[0141] The input quantities are not correlated with each other, so the composite uncertainty caused by the measurement of the inner diameter of the burner u 1 for: Its expanded uncertainty U 1 For: U 1 =k·u 1 =0.056, (k=2).

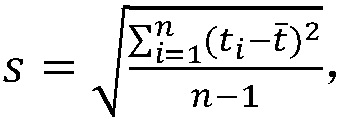

[0142] 2. Evaluation of measurement uncertainty of f...

Embodiment 2

[0162] Experimental object: No. 2 battery combustion test machine

[0163] 1. Evaluation of measurement uncertainty of burner inner diameter

[0164] The standard uncertainty component u introduced by the repeatability of the measurement 11 :

[0165] Perform 10 repeated measurements with equal precision on the 9.5mm piston diameter, and get the standard deviation u of a single experiment 11 =s≈0.022

[0166] Uncertainty component u introduced by caliper indication error 12 :

[0167] For a digital caliper with a measuring range of 300mm and a division value of 0.01mm, the indication error is ±0.04mm, which is evenly distributed, and the inclusion factor is So its standard uncertainty

[0168] The input quantities are not correlated with each other, so the composite uncertainty caused by the measurement of the inner diameter of the burner u 1 for: Its expanded uncertainty U 1 For: U 1 =k·u 1 =0.064, (k=2).

[0169] 2. Evaluation of measurement uncertainty of fl...

Embodiment 3

[0190] Experimental object: No. 3 battery combustion test machine

[0191] 1. Evaluation of measurement uncertainty of burner inner diameter

[0192] The standard uncertainty component u introduced by the repeatability of the measurement 11 :

[0193] Perform 10 repeated measurements with equal precision on the 9.5mm piston diameter, and get the standard deviation u of a single experiment 11 =s≈0.020;

[0194] Uncertainty component u introduced by caliper indication error 12 :

[0195] For a digital caliper with a measuring range of 300mm and a division value of 0.01mm, the indication error is ±0.04mm, which is evenly distributed, and the inclusion factor is So its standard uncertainty

[0196] The input quantities are not correlated with each other, so the composite uncertainty caused by the measurement of the inner diameter of the burner u 1 for: Its expanded uncertainty U 1 For: U 1 =k·u 1 =0.060, (k=2).

[0197] 2. Evaluation of measurement uncertainty of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com