Intelligent workshop digitalized production line information collection and monitoring management system based on cloud platform.

A technology of information collection, monitoring and management, applied in the direction of electrical digital data processing, manufacturing computing systems, data processing applications, etc., can solve the problems of low query efficiency, achieve convenient query, fast response to user needs, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

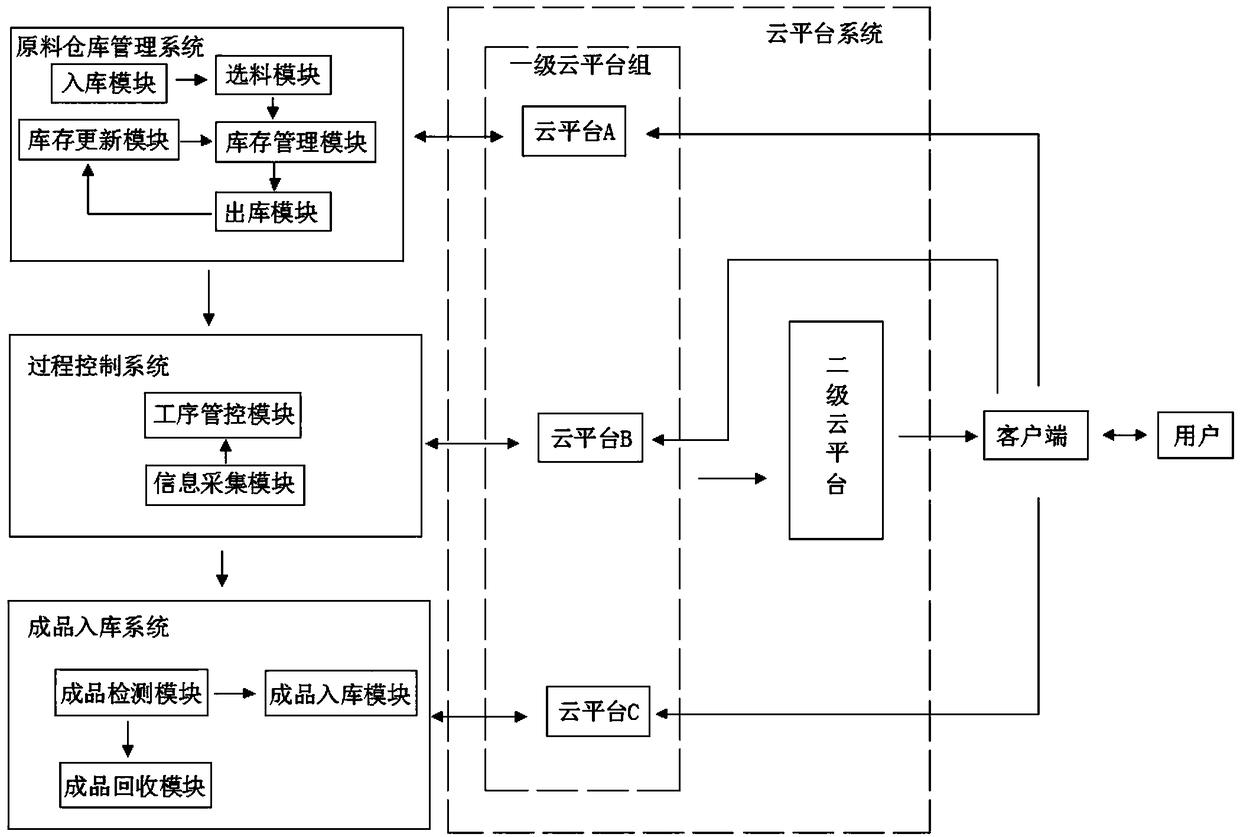

[0022] Such as figure 1 As shown, this embodiment provides a cloud platform-based smart workshop digital production line information collection and monitoring management system, including a raw material warehouse management system, a process control system, a finished product storage system, a cloud platform system, and a client. The cloud platform The system includes a first-level cloud platform group and a second-level cloud platform, and the first-level cloud platform group includes cloud platform A, cloud platform B and cloud platform C that communicate with the raw material warehouse management system, process control system and finished product storage system respectively;

[0023] The first-level cloud platform group uploads the collected information to the second-level cloud platform for storage, and there is one-way communication between the second-level cloud platform and the client. When the user needs to query data through the client, the client communicates with cl...

Embodiment 2

[0027] This embodiment is further optimized on the basis of Embodiment 1, specifically:

[0028] The raw material warehouse management system includes a warehouse-in module, a material selection module, an inventory management module, a warehouse-out module and an inventory update module. The material selection module is responsible for screening the raw materials sent by the warehouse-in module, and qualified raw materials are passed through the warehouse. The module registers out of the warehouse, and the inventory update module is responsible for updating the raw material inventory in the inventory management module.

[0029] The process control system includes a process control module and an information collection module. The process control module is responsible for managing the processing procedures on the production line and managing the production parameters of each processing procedure; the information collection module is responsible for the production of each process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com