Rapid heat dissipation method and device based on semiconductor refrigeration technology

A technology of heat dissipation device and heat dissipation method, which is applied in the direction of cooling/ventilation/heating transformation, modification of power electronics, electrical components, etc., which can solve the problems of discounted cooling effect, generation of water vapor, condensation, and rapid heat dissipation, etc., to achieve control Convenience, improved equipment life, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

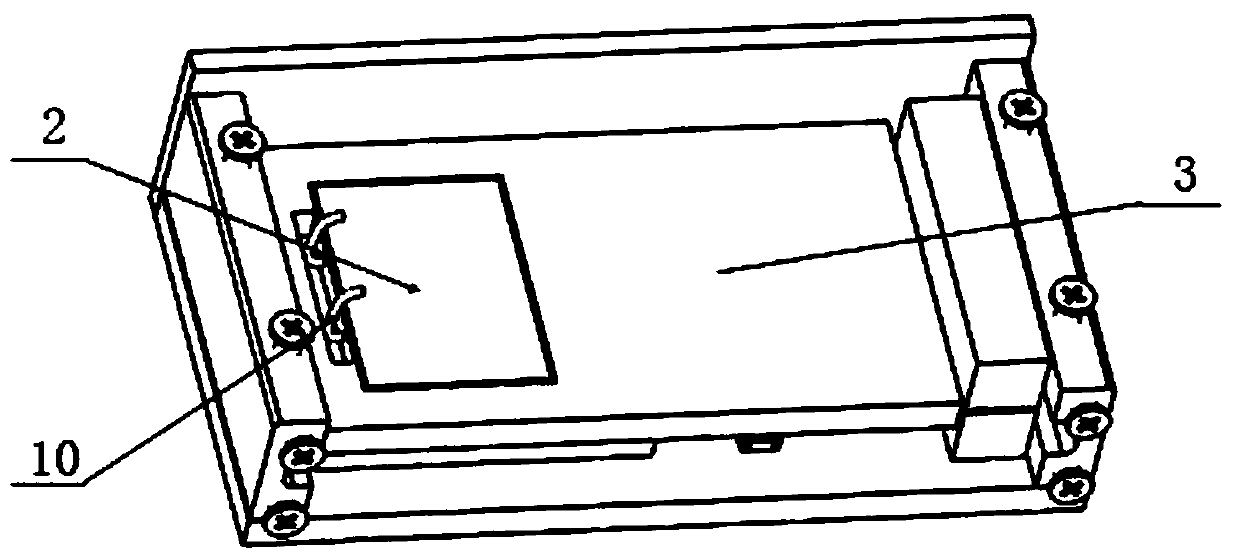

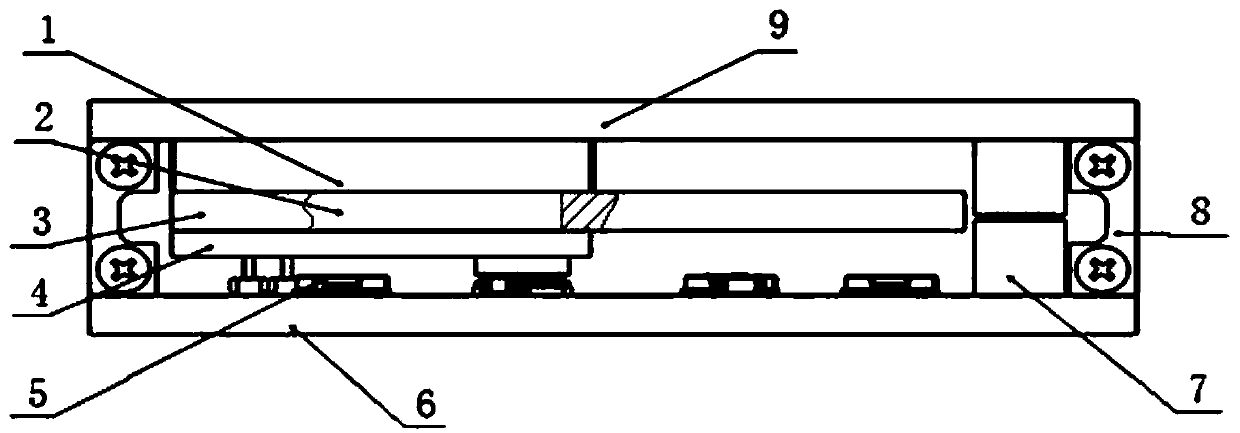

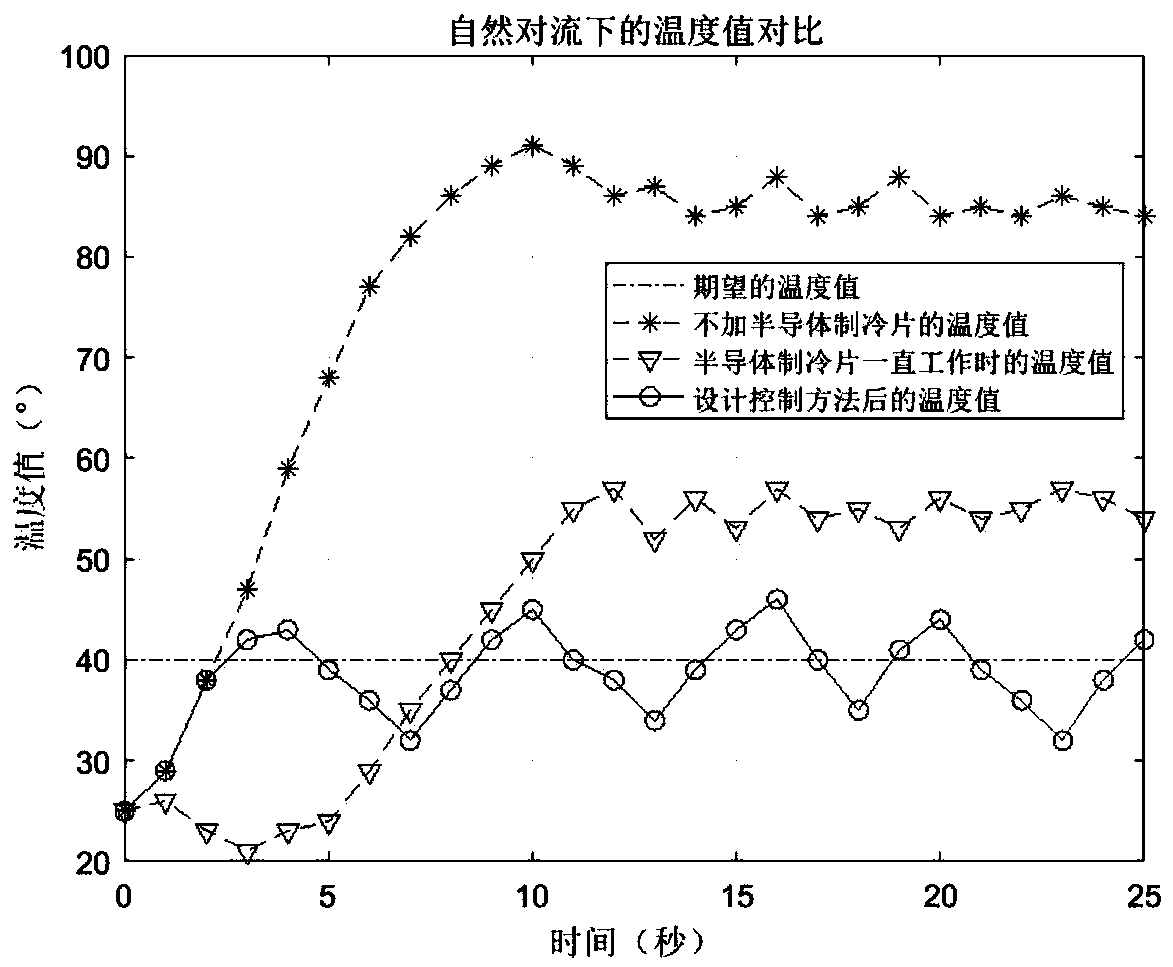

[0045] Such as figure 1 , figure 2 As shown, the copper foil of the aluminum-based circuit board 6 faces upward, and the power chip 5 is arranged on the copper foil surface by welding, and the heat generated by the power chip 5 can pass through the copper foil-aluminum-based circuit board of the aluminum-based circuit board 6 6. Aluminum base plate - This pathway emits emissions from the outside world. The aluminum-based circuit board 6 is connected to the top wall 9 through the side wall 8, and the top wall 9 is made of metal, that is, the outer wall for heat dissipation. The side wall 8 is made of heat insulating material, which prevents heat exchange between the top wall 9 and the aluminum-based circuit board 6 . Of course, the side wall 8 can also be made of metal, which can help the top wall 9 dissipate heat. At this time, a small heat insulating pad is provided between the side wall 8 and the aluminum-based circuit board.

[0046] There is a whole heat insulation pa...

Embodiment 2

[0056] The circuit board can be an epoxy resin non-metallic circuit board. The non-metallic circuit board and the heat insulation pad form the inner cavity that wraps the power chip 5. At this time, the heat dissipation of the power chip 5 is mainly through the semiconductor cooling chip 2 in addition to the heat dissipation of the contact with the air. Heat dissipation to the top wall 9 .

Embodiment 3

[0058] Like Embodiment 1, the bottom surface of the aluminum-based circuit board 6 is also attached to the heat-absorbing end of a heat-conducting element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com