Environment-friendly high-resilience flame-retardant composite shell fabric

A flame-retardant composite and flame-retardant fabric technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of increased production difficulty, poor flame retardancy, and unsatisfactory technical solutions, etc. Achieve the effect of avoiding formaldehyde and toxic and harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

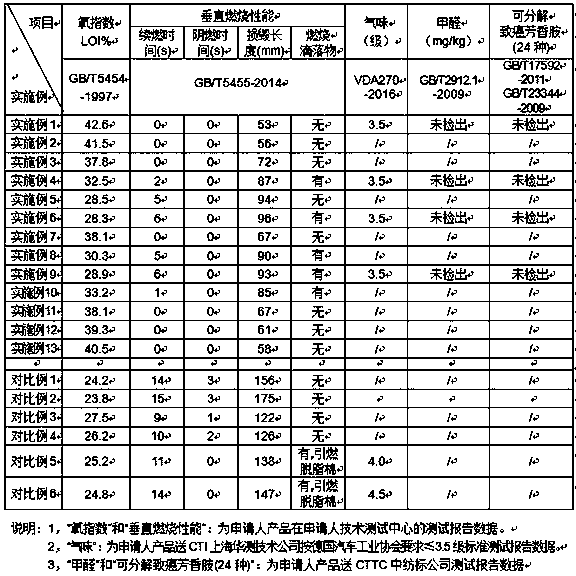

Examples

Embodiment 1

[0022] In this embodiment, the purpose is to manufacture and produce highly flame-retardant, environmentally friendly, high-resilience, and flame-retardant composite fabrics.

[0023] The manufacturing method of the flame retardant fabric layer is as follows: the warp and weft yarns are all made of flame retardant polyester fiber, the warp direction uses flame retardant 770DATY air variable yarn (phosphorus content is 7100ppm), and the weft direction uses flame retardant 13s / 2 strands ( Phosphorus content 6400ppm), woven into variable jacquard gray fabric on electronic dobby loom, after dyeing and setting, the width is 150cm, and the weight is 265g / m 2 Jacquard flame-retardant fabric, sampling test flame retardancy, its oxygen index LOI is 38.6%.

[0024] The manufacturing method of the flame-retardant intermediate layer is as follows: use 16kg of fineness 3D flame-retardant polyester two-dimensional crimped hollow staple fiber (use 3D flame-retardant polyester two-dimensional...

Embodiment 2

[0028] In this embodiment, the purpose is to manufacture and produce highly flame-retardant, environmentally friendly, high-resilience, and flame-retardant composite fabrics.

[0029] Flame-retardant fabric layer manufacture method is: choose the width 150cm of embodiment 1, heavy 265g / m 2 , the oxygen index LOI is the jacquard flame-retardant fabric of 38.6% as the flame-retardant fabric layer of this embodiment.

[0030]The manufacturing method of the flame-retardant intermediate layer is: use 12kg of fineness 6D flame-retardant polyester hollow staple fiber (containing about 6400ppm phosphorus), 56kg of fineness 3D flame-retardant polyester staple fiber (containing about 6400ppm phosphorus), 12kg of fineness 6D non-flame-retardant hollow staple fiber, Produced into a thickness of about 4.5mm, a width of 152cm, and a weight of 150g / m 2 The fluffy flame-retardant needle-punched cotton was sampled to test the flame retardancy, and its oxygen index LOI was 39.8%.

[0031] Sel...

Embodiment 3

[0034] In this embodiment, the purpose is to manufacture and produce highly flame-retardant, environmentally friendly, high-resilience, and flame-retardant composite fabrics.

[0035] The manufacturing method of the flame-retardant fabric layer is as follows: the warp and weft yarns are made of flame-retardant polyester fibers with a phosphorus content of 6400ppm, that is, the warp direction uses 620DATY flame-retardant air-variable yarn, and dyes two different colors respectively, and the weft direction uses 4 Flame-retardant chenille yarn of public count, 620DATY flame-retardant space-changing yarn, 20-inch strand yarn, and weft yarns are dyed into three different colors, and are woven into jacquard yarn-dyed fabrics on electronic jacquard rapier looms. After dyeing factory After shaping treatment, the width is 152cm and the weight is 510g / m 2 The yarn-dyed jacquard flame-retardant fabric was sampled for combustion performance testing, and its oxygen index LOI was 37.5%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com