Recovery method of phenylacetic acid in 6-aminopenicillanic acid enzymatic aqueous solution

A recovery method, the technology of phenylacetic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of air, water environment and water source pollution, unfavorable health, high risk, etc., to achieve economic and environmental protection Win-win, simplification of operation and steps, good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

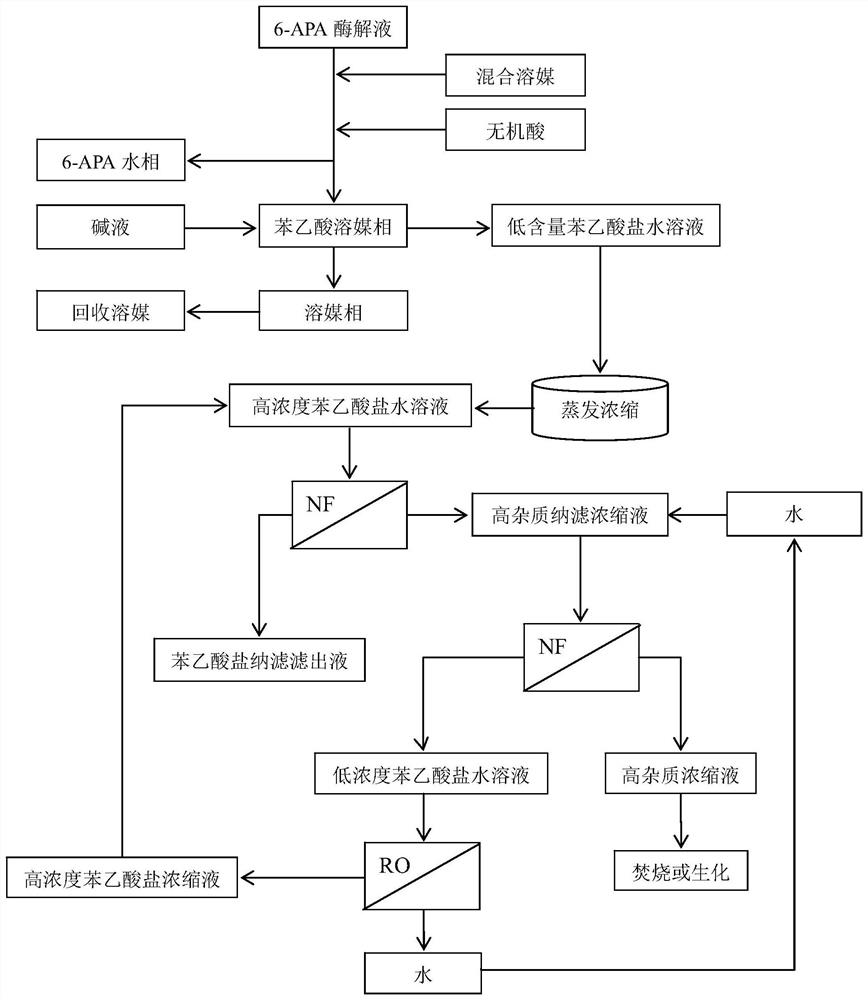

[0022] In the preparation of the step (1) phenylacetate aqueous solution, the pH of the 6-APA enzymatic aqueous solution is adjusted to acidity with an inorganic acid, and then mixed solvents are used to extract the phenylacetic acid in the 6-APA enzymatic aqueous solution, which is separated to obtain 6-APA water phase and solvent phase containing phenylacetic acid; adding lye to the solvent phase containing phenylacetic acid, layering to obtain the aqueous phase containing phenylacetic acid salt, after evaporation and concentration, to obtain concentrated phenylacetic acid salt liquid.

[0023] In the step (1), the 6-APA enzymatic aqueous solution means that penicillin G is decomposed by penicillin acylase to generate 6-APA and phenylacetic acid, and the enzymatic hydrolysis solution after filtering and removing impurities, this part of the enzymatic hydrolysis solution Contains the product 6-APA, and also contains the by-product phenylacetic acid, wherein the concentration ...

Embodiment 1

[0034] (1) Preparation of sodium phenylacetate aqueous solution

[0035] Take 50L of 6-APA enzymatic aqueous solution (the content of phenylacetic acid is 22.4g / L), the pH value is 8.1, at a temperature of 10°C, use 32% (v / v) concentrated hydrochloric acid to adjust the pH to 1.0, then add 50L butyl acetate / The n-butanol mixed solvent (n-butanol accounts for 14% (volume)) was fully stirred, and the extract was collected after standing to separate 49.4L (phenylacetic acid content 20.8g / L); use 40% (w / v) sodium hydroxide The solution adjusted the pH of the extract to 10.5, stirred well and then separated and collected the heavy phase 6.6L (phenylacetic acid content 151.3g / L); then, vacuum distillation concentrated the phenylacetic acid content to 263.5g / L, volume 3.8L.

[0036] (2) preparation of purified sodium phenylacetate aqueous solution

[0037] The concentrated solution containing sodium phenylacetate obtained in step (1) is removed by a nanofiltration membrane with a m...

Embodiment 2

[0041] (1) Preparation of sodium phenylacetate aqueous solution

[0042] Take 50L of 6-APA enzymatic aqueous solution (phenylacetic acid content 22.3g / L), the pH value is 8.0, the temperature is 11°C, use 32% (v / v) concentrated hydrochloric acid to adjust the pH to 1.0, and then add 100L butyl acetate / normal Butanol mixed solvent (n-butanol accounts for 24.5% (volume)) was fully stirred, and the extract was collected after standing to separate 99.2L (11.0g / L); use 40% (w / v) sodium hydroxide solution to adjust the extract The pH was 10.5, and after being fully stirred, the heavy phase was collected by stratification at 6.8 L (154.9 g / L); then, the content of phenylacetic acid was concentrated to 297.9 g / L by vacuum distillation, and the volume was 3.5 L.

[0043] (2) preparation of purified sodium phenylacetate aqueous solution

[0044] The concentrated solution containing sodium phenylacetate obtained in step (1) is removed by a nanofiltration membrane with a molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com