Litchi brandy and preparation method thereof

A technology for brandy and lychee, applied in the field of lychee brandy and its preparation, can solve problems such as bad taste, achieve the effects of thick taste, prevent the growth of miscellaneous bacteria, and improve flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

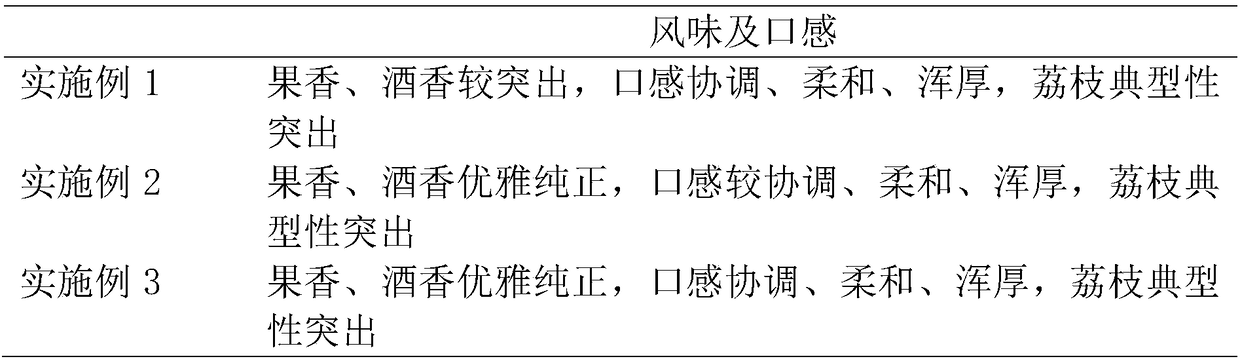

Examples

Embodiment 1

[0031] A preparation method of lychee brandy, comprising the steps of:

[0032] 1) Raw material selection and treatment: select fresh lychees, remove branches and leaves, diseased fruit, rotten fruit, rotten fruit, immature fruit, wash, drain, peel, remove core, and remove rotten pulp and residual core;

[0033] 2) Squeeze the lychee meat, collect the juice, add 0.8w / w% pectinase to the juice, add 1.0w / w% Nimzi fruit extract to the juice, mix well, enzymatic hydrolysis temperature 20-22°C, enzymatic The hydrolysis pH is 3.2-3.5, the enzymatic hydrolysis time is 6h, and transferred to the fermenter after the end;

[0034] 3) Fermentation: adjust the pH value to 3.0, the alcohol content to 4°, and then add high-activity yeast liquid. The high-activity yeast liquid is to add high-activity dry yeast to 10 times the weight of pure water at 33-35°C, dissolve It is obtained after activating for 30 minutes, the amount of high-activity yeast liquid added is 8% of the weight of the fer...

Embodiment 2

[0044] A preparation method of lychee brandy, comprising the steps of:

[0045] 1) Raw material selection and treatment: select fresh lychees, remove branches and leaves, diseased fruit, rotten fruit, rotten fruit, immature fruit, wash, drain, peel, remove core, and remove rotten pulp and residual core;

[0046] 2) Squeeze the lychee meat, collect the juice, add 1.0w / w% pectinase to the juice, add 1.0w / w% Nimeng fruit extract to the juice, mix well, enzymatic hydrolysis temperature 20-22°C, enzymatic The hydrolysis pH is 3.2-3.5, the enzymolysis time is 8h, and transferred to the fermenter after the end;

[0047] 3) Fermentation: adjust the pH value to 3.0, the alcohol content to 4°, and then add high-activity yeast liquid. The high-activity yeast liquid is to add high-activity dry yeast to 10 times the weight of pure water at 33-35°C, dissolve It is obtained after activating for 30 minutes, the amount of high-activity yeast liquid added is 10% of the weight of the fermentati...

Embodiment 3

[0057] A preparation method of lychee brandy, comprising the steps of:

[0058] 1) Raw material selection and treatment: select fresh lychees, remove branches and leaves, diseased fruit, rotten fruit, rotten fruit, immature fruit, wash, drain, peel, remove core, and remove rotten pulp and residual core;

[0059] 2) Squeeze the lychee meat, collect the juice, add 1.0w / w% pectinase to the juice, add 1.5w / w% Nimeng fruit extract to the juice, mix well, enzymatic hydrolysis temperature 20-22°C, enzymatic The hydrolysis pH is 3.2-3.5, the enzymolysis time is 8h, and transferred to the fermenter after the end;

[0060] 3) Fermentation: adjust the pH value to 3.0, the alcohol content to 4°, and then add high-activity yeast liquid. The high-activity yeast liquid is to add high-activity dry yeast to 10 times the weight of pure water at 33-35°C, dissolve It is obtained after activating for 30 minutes, the amount of high-activity yeast liquid added is 10% of the weight of the fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com