Pumping and cyclone conveying combined concrete spraying machine and spraying method thereof

A technology of concrete and combined pump, applied in the field of mining machinery and equipment, can solve the problems of difficult concrete material slump, complex process, material segregation, etc., to improve the efficiency of shotcrete operation, to have broad application prospects, and to solve the problem of pumping blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings.

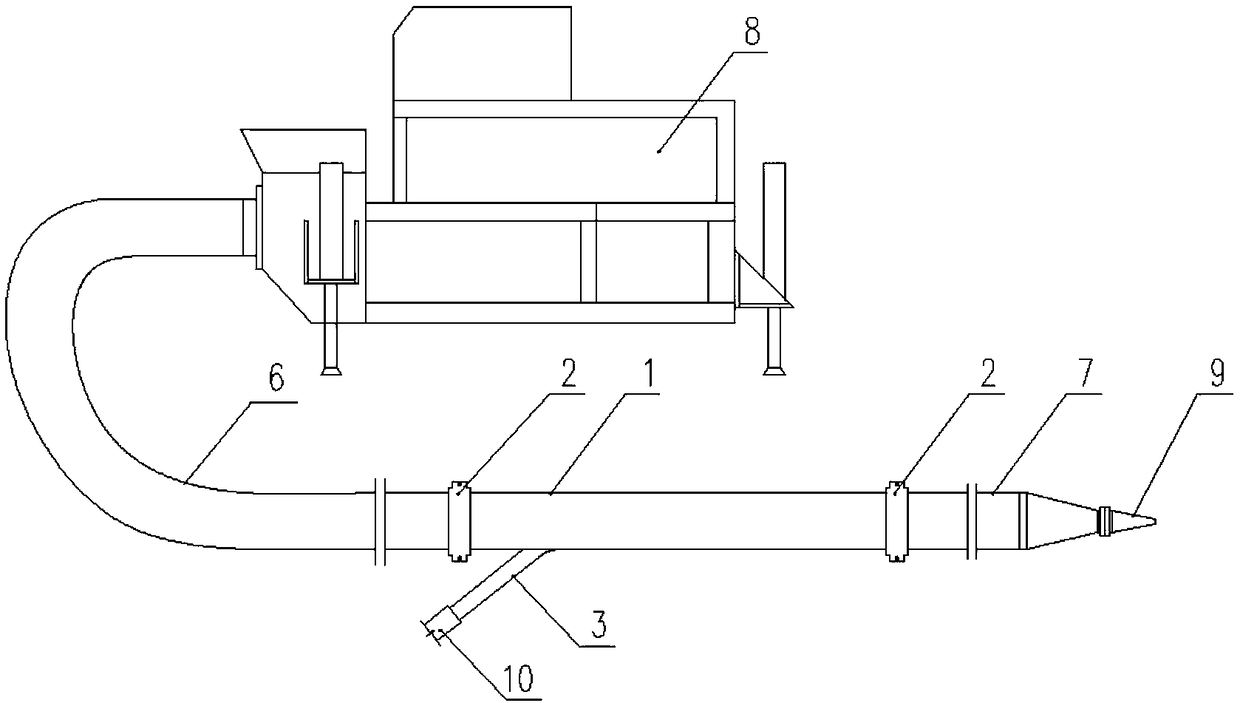

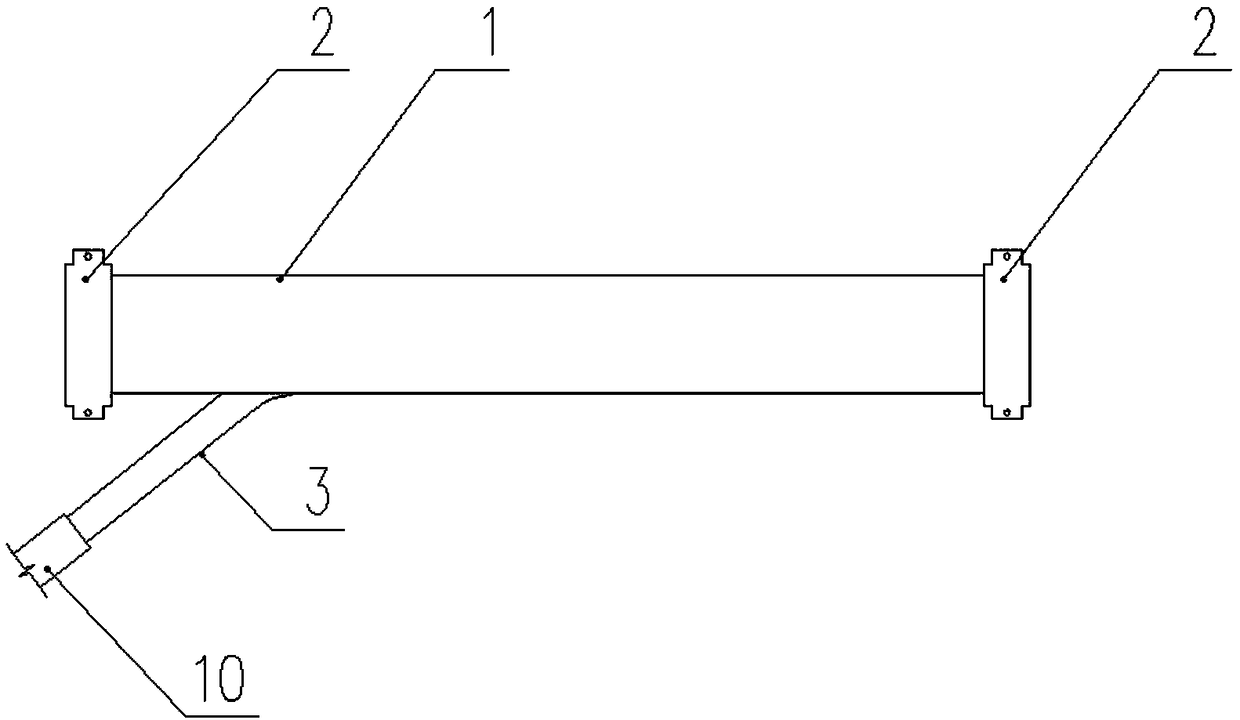

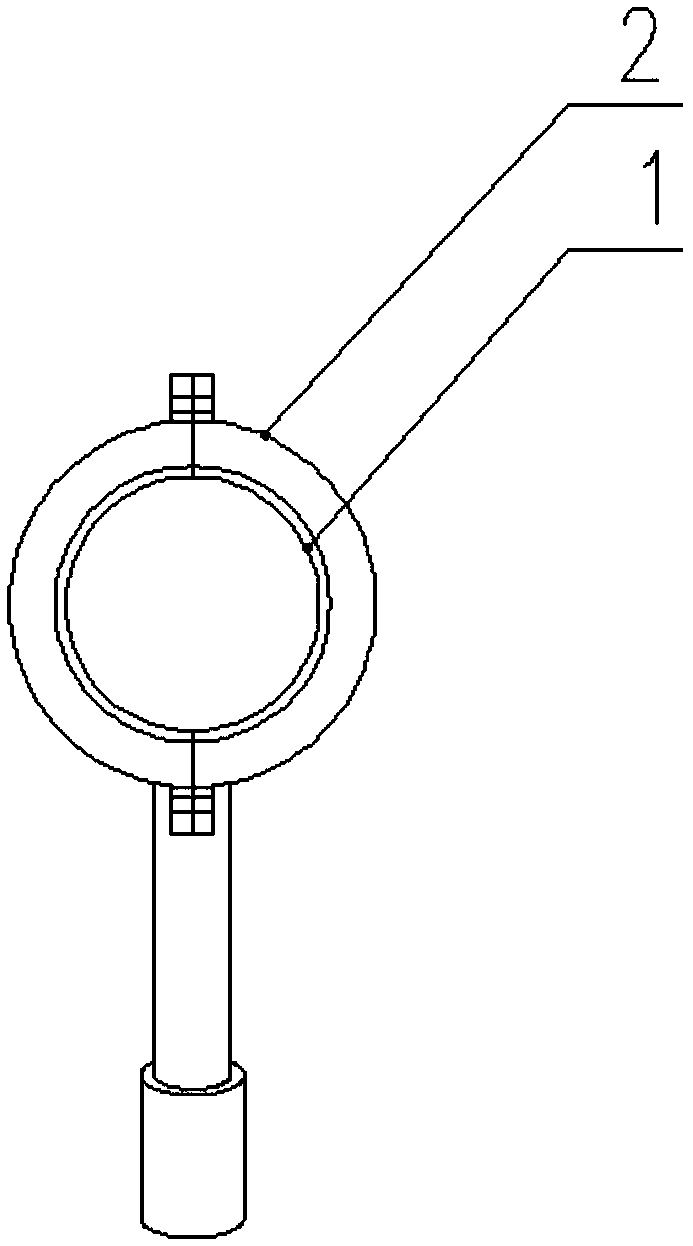

[0027] A concrete shotcrete machine combined with pumping and cyclone conveying, such as figure 1 As shown, it consists of a pumping system and a cyclone conveying system. Wherein, the pumping system includes a concrete pumping machine 8 and a pump material pipe 6 , and the cyclone conveying system includes a threaded cyclone pipe 1 , a feeding pipe 7 , an air inlet pipe 3 and a nozzle 9 . Such as Figure 4 As shown, the inner side of the threaded cyclone pipe 1 is processed with a spiral inner groove 5, which is used to control the rotation of the airflow and enhance the carrying capacity of the gas. An air intake pipe 3 is welded on the side wall of the threaded cyclone pipe 1, and the axial direction of the air intake pipe 3 is at a certain angle with the axial direction of the threaded cyclone pipe 1. The feeding pipe 7 connects the threaded cyclone pipe 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com