Modified heavy-duty gas turbine

A gas turbine and heavy-duty technology, which is applied in the direction of gas turbine devices, liquid fuel engines, mechanical equipment, etc., can solve the problem of high technical risk and long time. It usually takes 20 to 30 years from the first prototype to design and finalization, and it is not accepted by the market. problem, to achieve the effect of increasing power and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

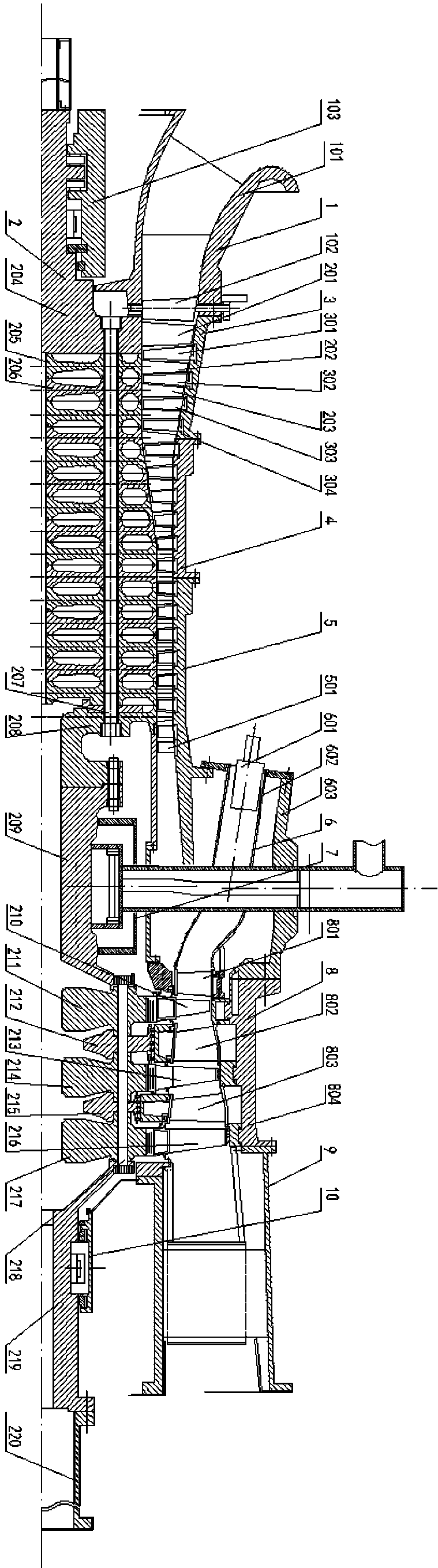

[0010] Example: such as figure 1 As shown, the present invention is a modified heavy-duty gas turbine, including an intake casing assembly 1, a rotor assembly 2, a compressor front stator assembly 3, a compressor middle stator assembly 4, a compressor rear stator assembly 5, a combustion chamber 6, The turbine subassembly 8, the exhaust diffuser assembly 9 and the bearing assemblies 101, 7, 10 etc. are composed. All stator components are all horizontal split structures. The gas turbine stator assembly includes intake casing assembly 1, compressor front stator assembly 3, compressor middle stator assembly 4, compressor rear stator assembly 5, combustion chamber 6, turbine stator assembly 8, front, middle and rear fulcrum bearings Assembly and exhaust diffuser 9, all stator assemblies are completely split horizontally. The gas turbine rotor assembly 2 is composed of working blades, discs, journals and tie rod bolts. The compressor and turbine rotors are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com