Fluidized drying device for new feed additive lysozyme dimer particles

A technology of lysozyme dimer and feed additive, which is applied in the direction of drying gas arrangement, heating to dry solid materials, drying solid materials, etc., can solve the problems of high temperature variability, achieve high production efficiency, fast drying, and avoid lysozyme The effect of protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

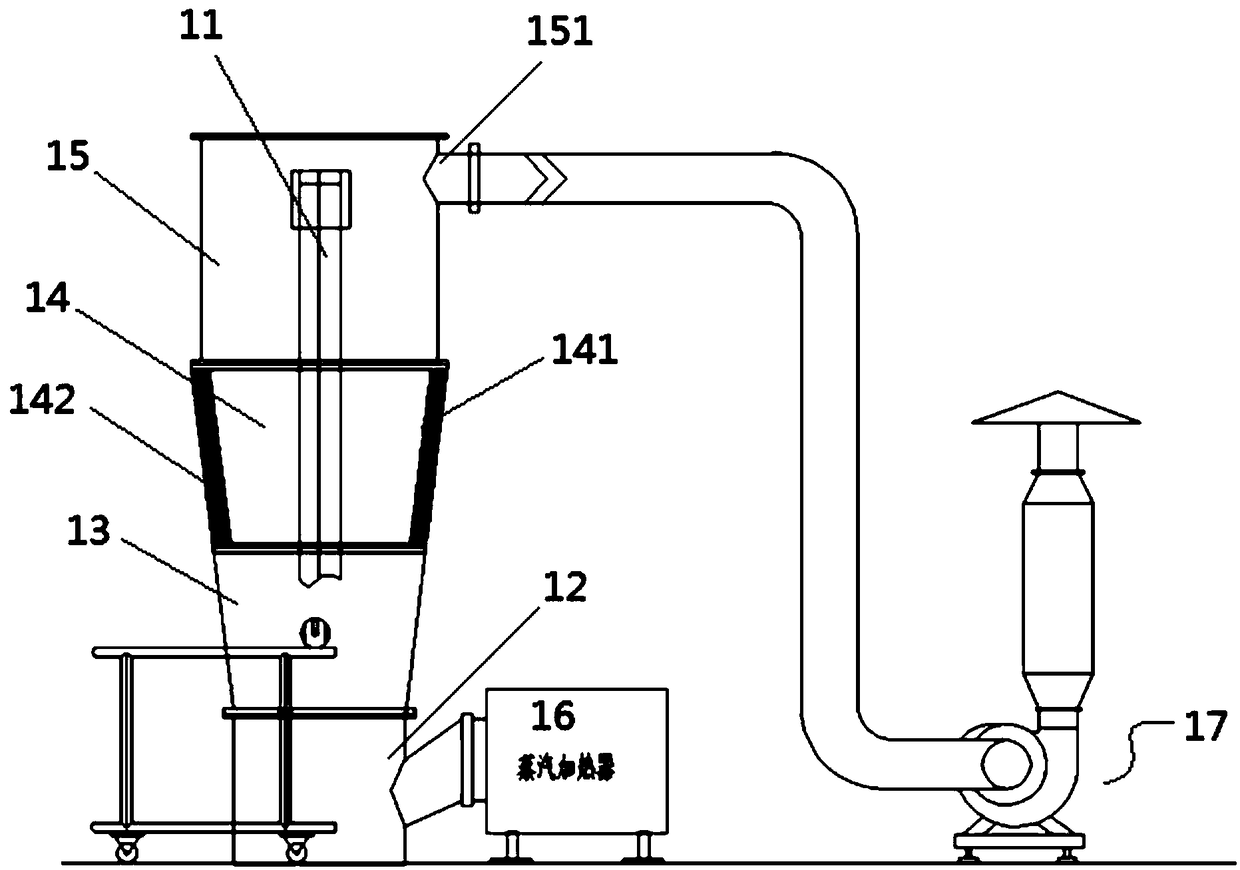

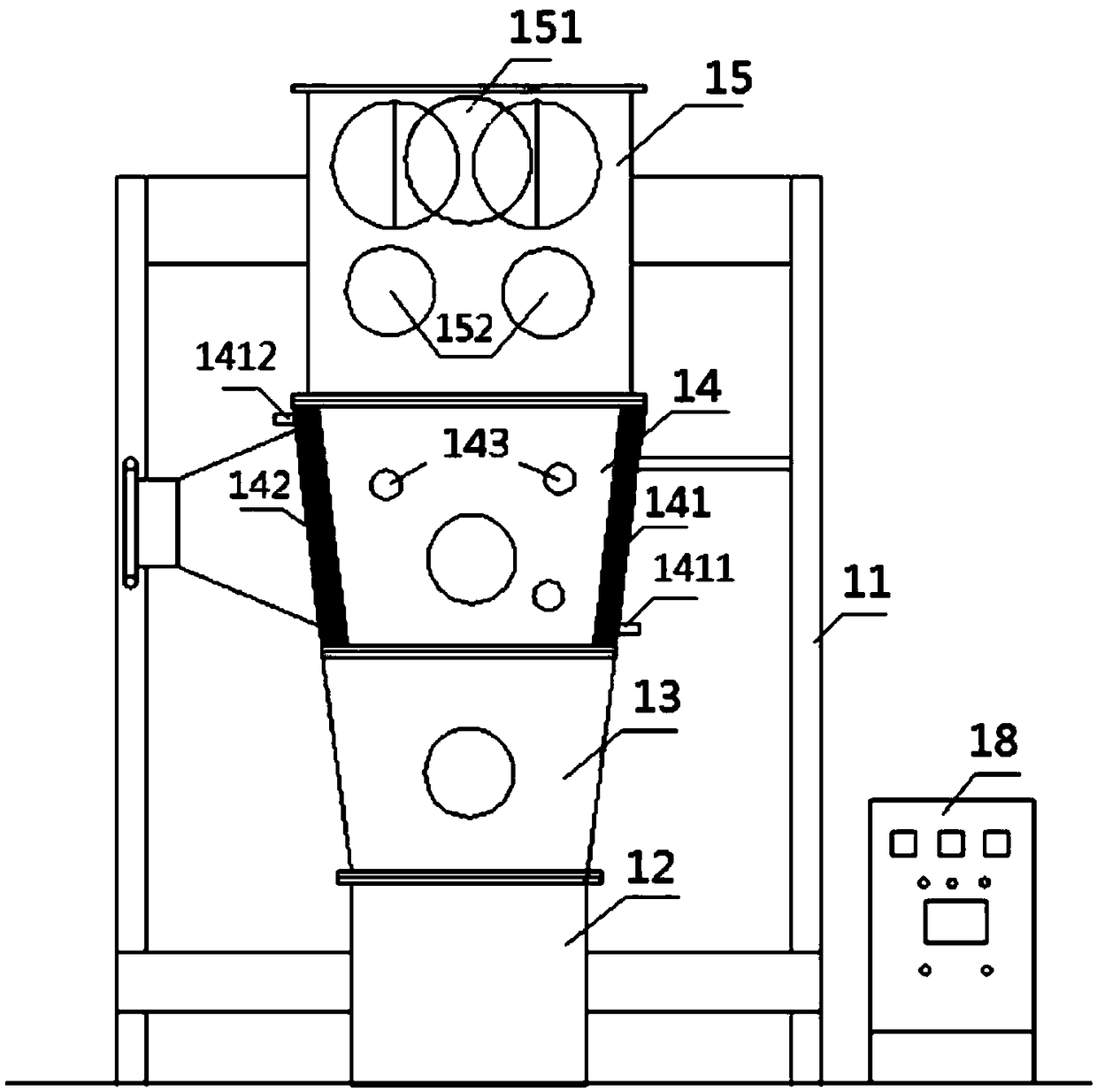

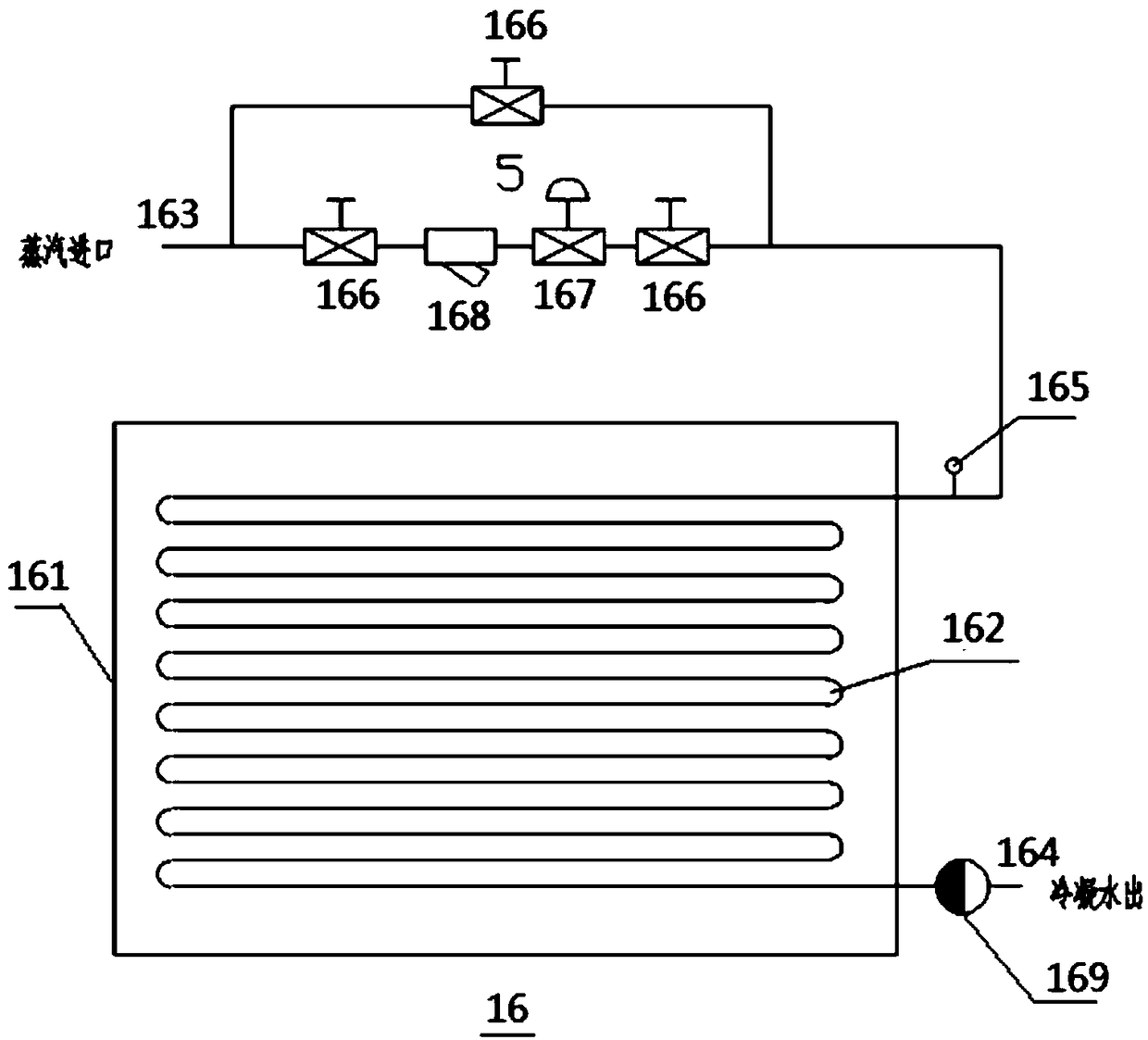

[0019] Such as figure 1 , figure 2 Shown is a boiling drying device for new feed additive lysozyme dimer granules according to the present invention, the device includes sequentially arranged from bottom to top and respectively fixed on the fixed frame 11: hot air inlet bin 12, material bin 13 . Particle boiling chamber 14 and particle recovery chamber 15. The hot air inlet chamber 12 is connected to a steam heater 16, which is used to provide hot air. A heating device 141 and a thermal insulation layer 142 are arranged in turn around the outer wall of the particle boiling chamber 14; the particle recovery chamber 15 is provided with an anti-particle leakage cloth bag (not shown in the figure) and an air-introduction outlet 151, the air-introduction The outlet is connected to the air-inducing device 17 through the air-introducing duct, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com