Patterned substrate and light emitting diode wafer

A light-emitting diode and patterning technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reducing epitaxial quality and tunneling difference, improving epitaxial quality, reducing compressive stress and tunneling difference. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

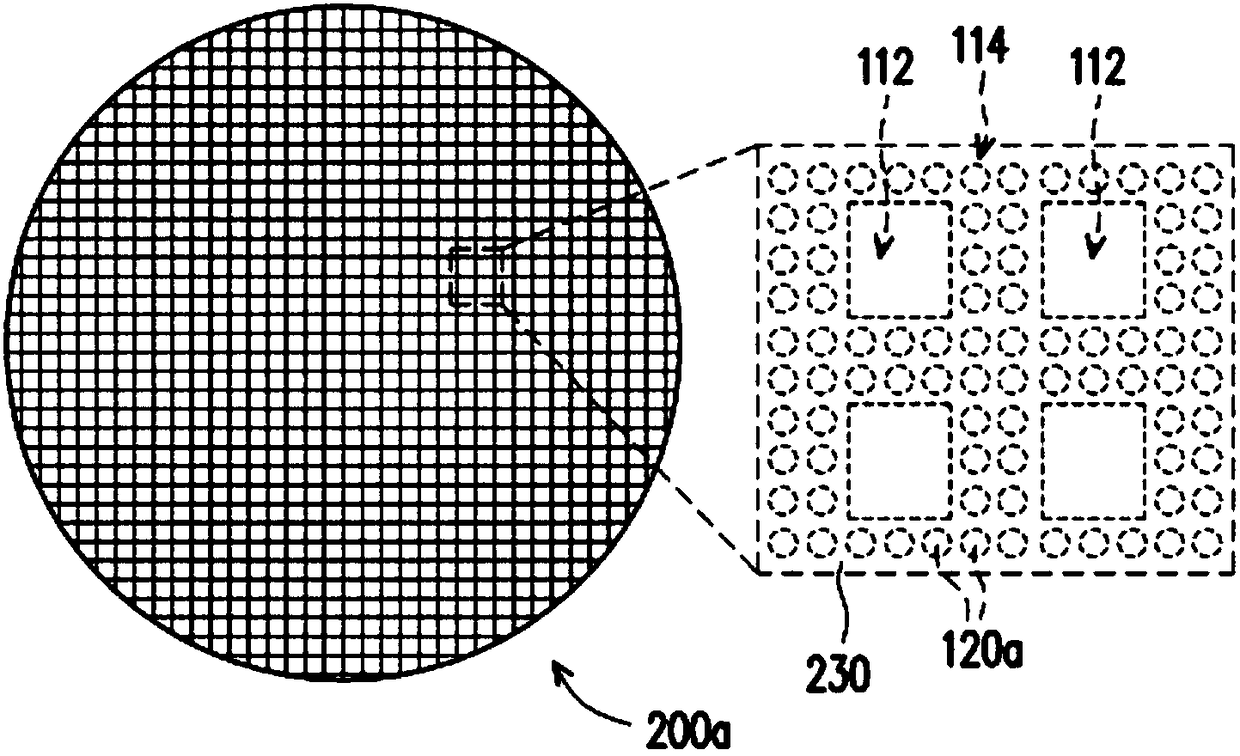

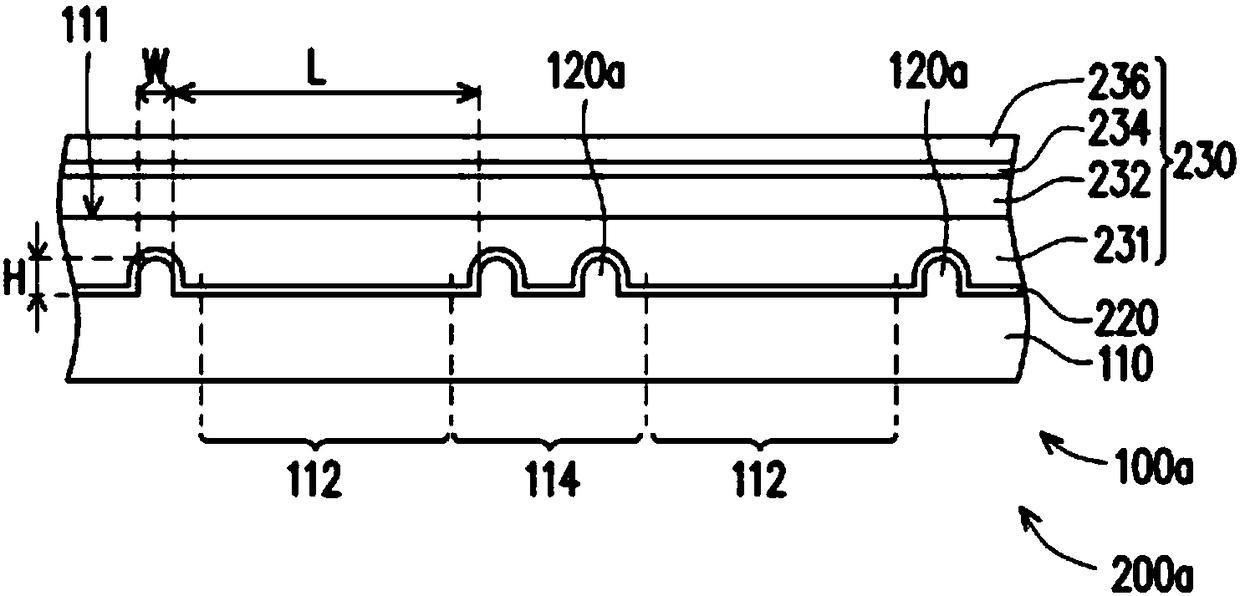

[0050] Figure 1A A schematic top view of an LED wafer according to an embodiment of the present invention is shown. Figure 1B shown as Figure 1A A partial cross-sectional schematic of a light-emitting diode wafer. Please also refer to Figure 1A and Figure 1B , the LED wafer 200a of this embodiment includes a patterned substrate 100a , a buffer layer 220 and an epitaxial structure layer 230 . The patterned substrate 100a of this embodiment includes a substrate 110 and a plurality of pattern structures 120a. The substrate 110 has at least one device configuration area 112 ( Figure 1A and Figure 1B Schematically shows a plurality of) and the cutting area 114 surrounding the component placement area 112 . The pattern structure 120 a is integrally formed with the substrate 110 and located in the cutting area 114 of the substrate 110 . The pattern structures 120 a are separated from each other and distributed in the cutting area 114 .

[0051] In detail, the patterned su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com