Light-emitting diode (LED) structure

A technology of light-emitting diodes and light-emitting layers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of attenuation of light emitted from the structure of light-emitting diodes, the inability to improve external quantum efficiency, and the reduction of crystallinity of n-type doped semiconductor layers. Effect of increasing internal quantum efficiency, improving external quantum efficiency, and good luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

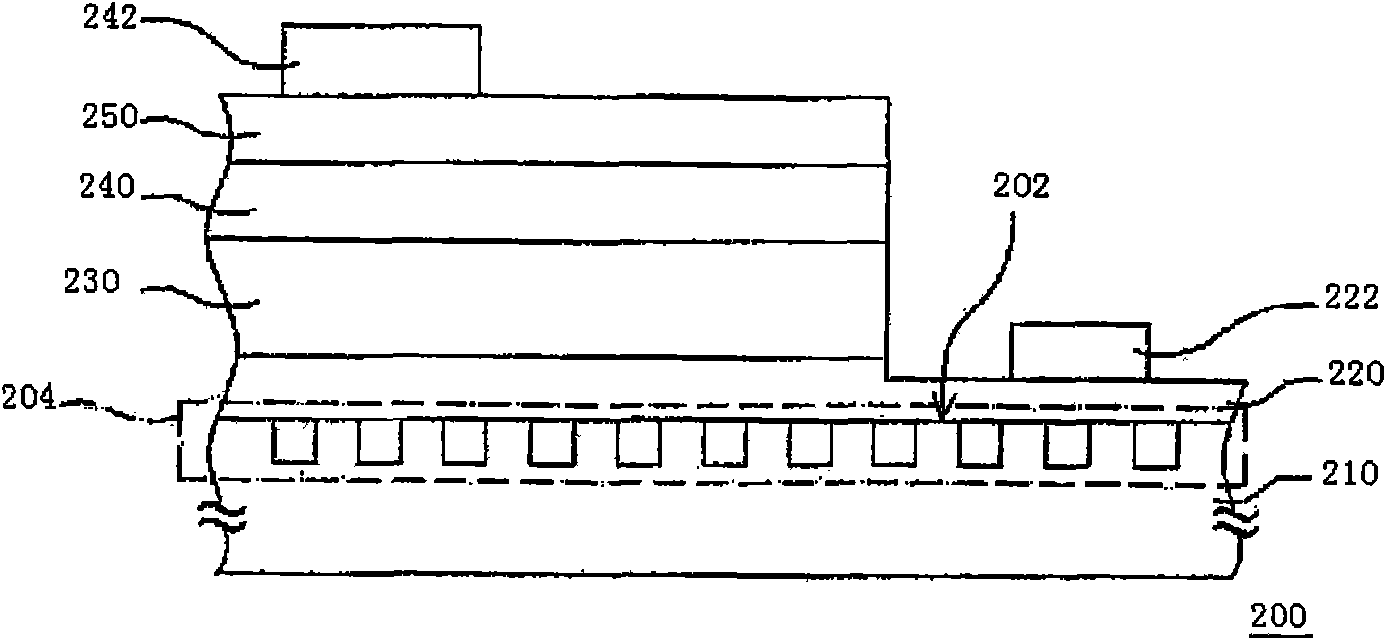

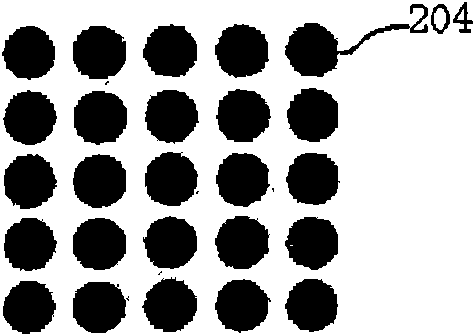

[0022] figure 2 It is a schematic cross-sectional view of the light emitting diode structure of the present invention. Please refer to figure 2 , the LED structure 200 is mainly composed of a substrate 210 , a first-type doped semiconductor layer 220 , an electrode 222 , a light-emitting layer 230 , a second-type doped semiconductor layer 240 and an electrode 242 . Wherein, the material of the substrate 210 is, for example, silicon, sapphire, silicon carbide or spinel, and the substrate 210 has a surface 202 and a plurality of cylindrical photonic crystals 204 located on the surface 202 .

[0023] As mentioned above, the photonic crystals 204 are, for example, raised patterns or grooves, and the method of forming these photonic crystals 204 is, for example, performing photolithography and etching processes on the substrate 210 to form cylindrical raised patterns or grooves on the surface 202. groove. In particular, the photonic crystals 204 are periodically arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com