High-quality silicon carbide epitaxial growth technology

A high-quality silicon carbide, epitaxial growth technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of epitaxial quality reduction, inability to completely eliminate substrate propagation, etc., and achieve improved characteristics and yield, reproducible Highly flexible and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

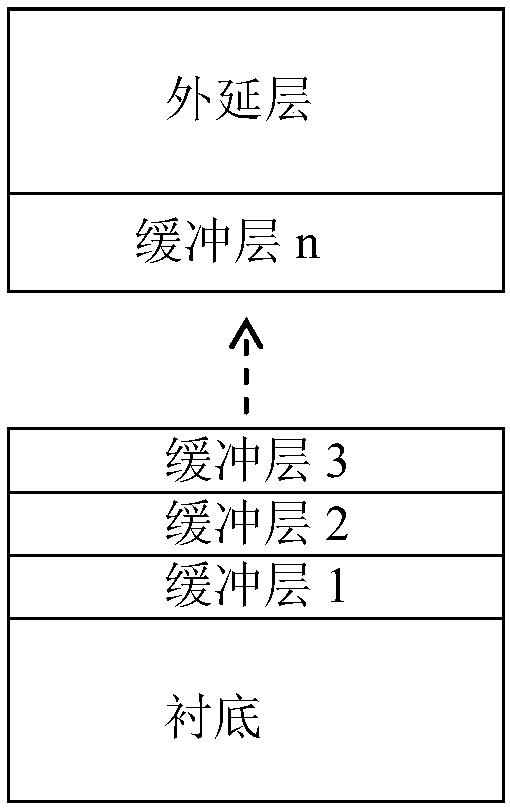

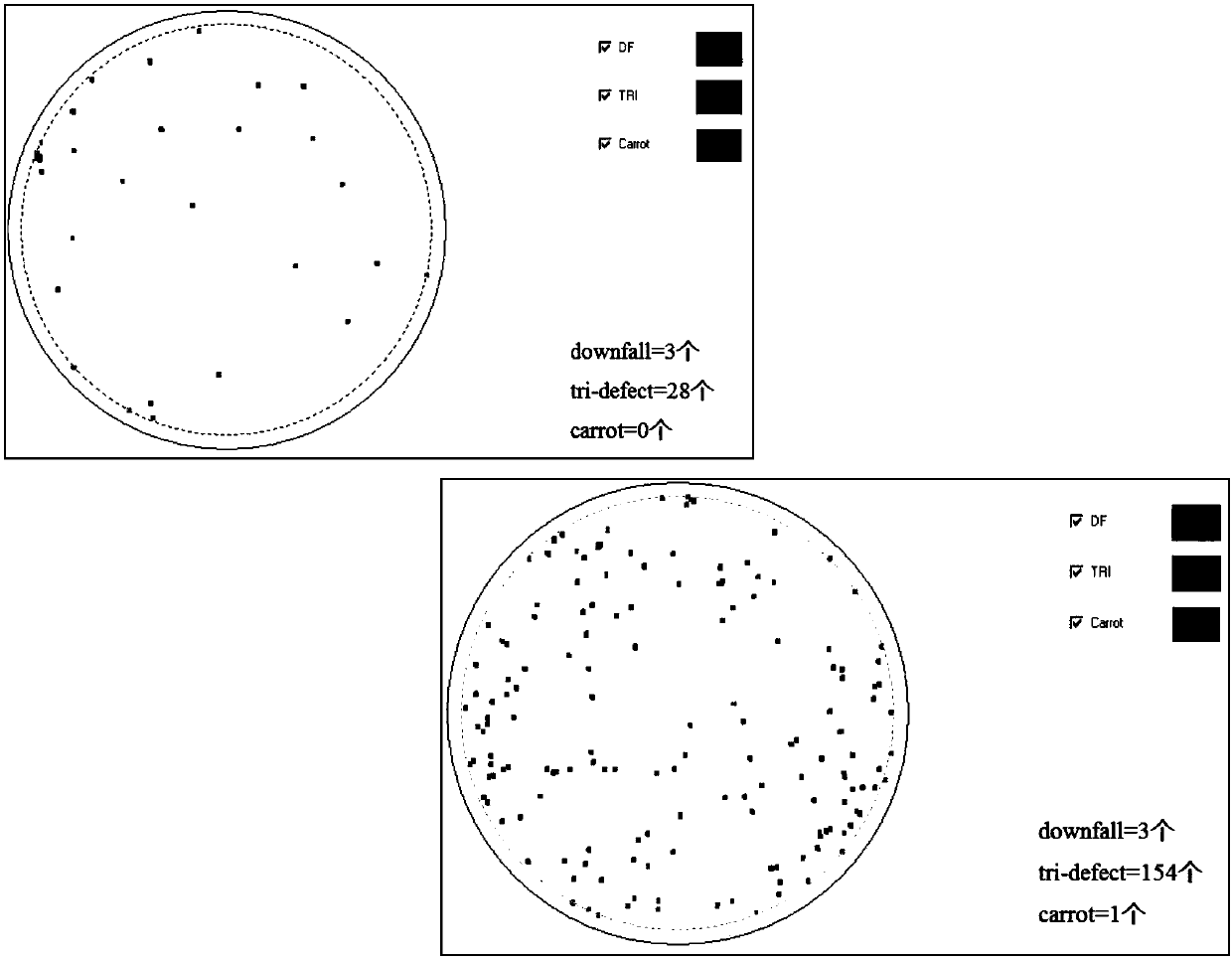

[0025] Provides a nitrogen doping concentration of 1 x 10 18 atoms / cm 3 SiC substrate, 2 layers grown by CVD with a nitrogen doping concentration of 1×10 18 atoms / cm 3 buffer layer, wherein: the growth rate of the first layer is 5 μm / h, and the thickness is 0.5 μm; the growth rate of the second layer is 10 μm / h, and the thickness is 0.5 μm. Then grow on the uppermost buffer layer with a nitrogen doping concentration of 1×10 16 atoms / cm 3 The epitaxial layer, the growth rate of the epitaxial layer is 15 μm / h, and the thickness is 10 μm. As a comparative example, a single buffer layer with a thickness of 10 μm was continuously grown on the above-mentioned SiC substrate at a growth rate of 5 μm / h and then an epitaxial layer was grown, and other control conditions were the same. Detect the defect distribution situation of the epitaxial wafer of embodiment 1 and comparative example, see figure 1 , Visible defects are significantly reduced, improving the epitaxial quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com