Straw crusher with long service life

A technology of straw shredder with long service life, which is applied in application, agricultural machinery and tools, cutting equipment, etc. It can solve the problems of reducing the life of the cutter head and inconvenient replacement of the cutter head, etc., and achieves prolonging the service life, simple structure, and reducing rapid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

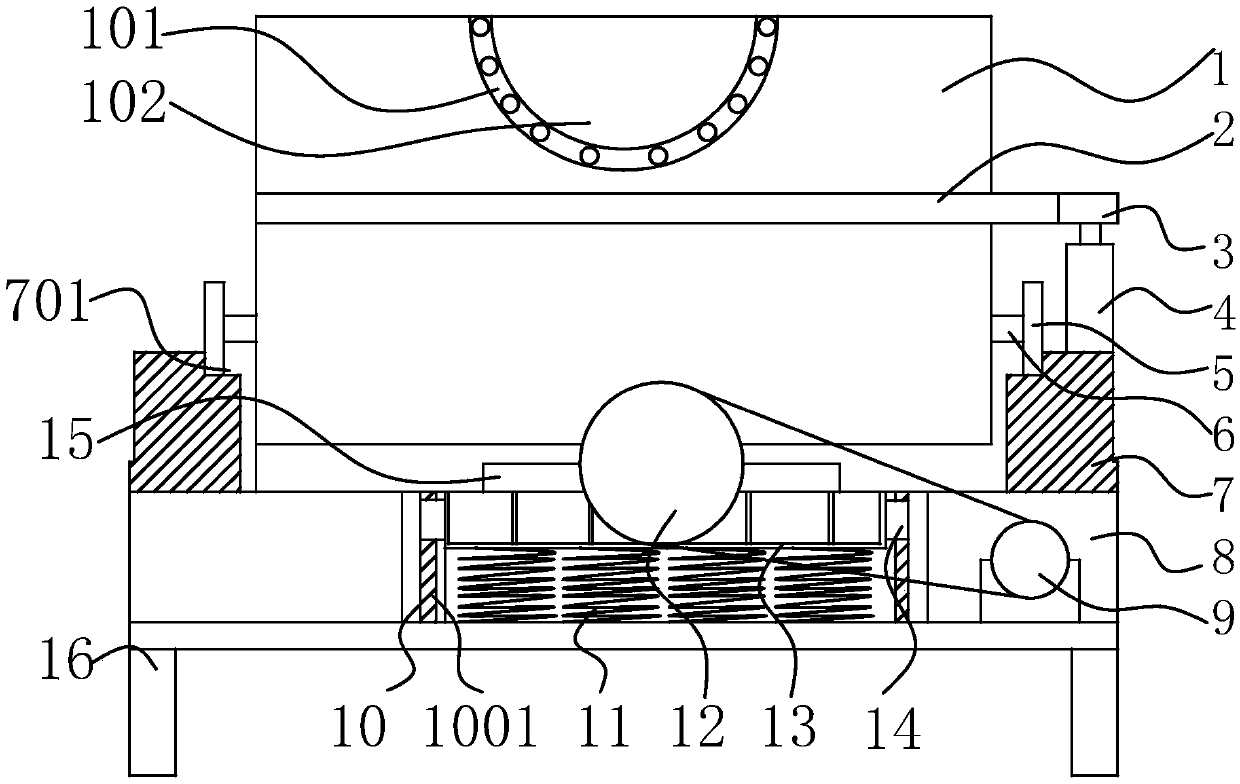

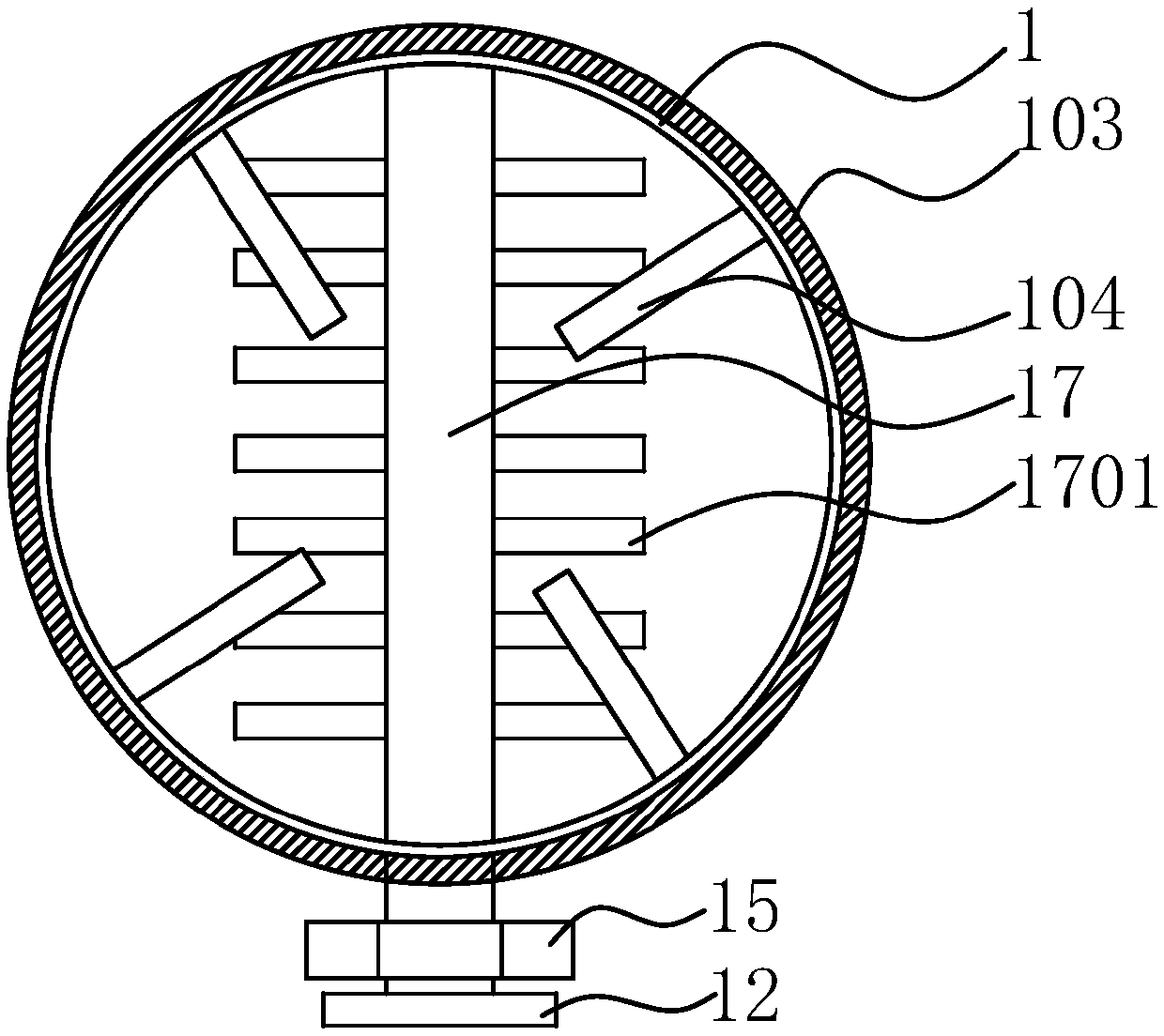

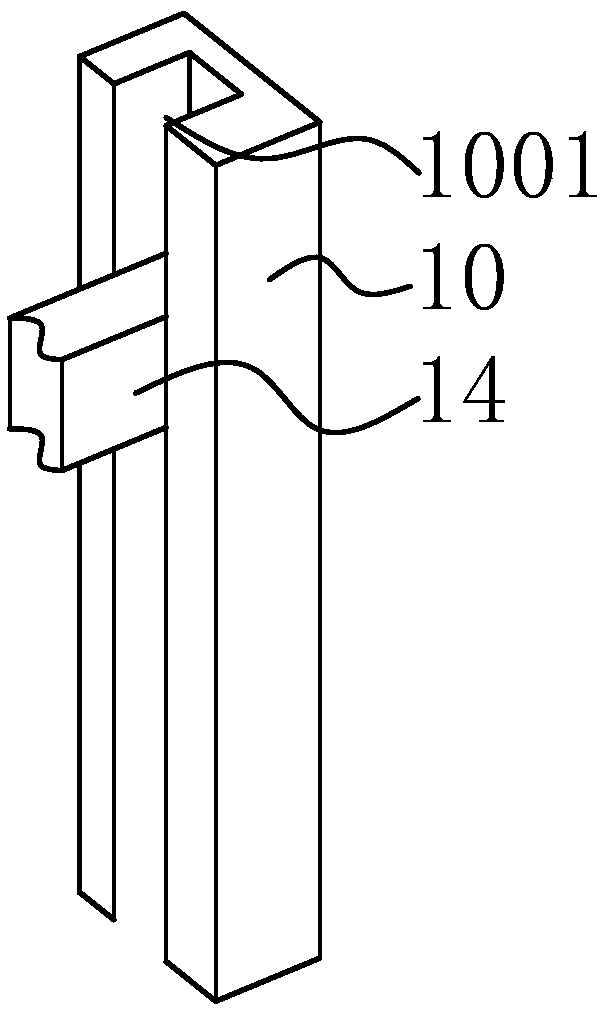

[0018] like figure 1 , figure 2 As shown, the present invention provides a straw grinder with a long service life, comprising a chassis 8, a drum 1 and a crushing device, the upper surface of the chassis 8 is provided with an annular support 7, and the upper surface of the support 7 is provided with an annular The chute 701 and the annular chute 701 are slidingly provided with a roller 5, the roller 5 is connected to the bottom of the outer wall of the drum 1 through the connecting rod 6, the middle part of the outer wall of the drum 1 is provided with a ring gear 103, and the ring gear 103 is connected to the outer wall of the drum 1 through the chain 2. The first motor 4 on the support 7 is connected by transmission. The crushing device includes a rotating shaft 17 arranged at the bottom of the drum 1 and a shock absorbing device. The surface of the rotating shaft 17 is evenly provided with a cutter head 1701. The bearing seat 15 is equipped with a driven wheel 12, and the...

Embodiment 2

[0023] like figure 1 , figure 2 As shown, the present invention provides a straw grinder with a long service life, comprising a chassis 8, a drum 1 and a crushing device, the upper surface of the chassis 8 is provided with an annular support 7, and the upper surface of the support 7 is provided with an annular The chute 701 and the annular chute 701 are slidingly provided with a roller 5, the roller 5 is connected to the bottom of the outer wall of the drum 1 through the connecting rod 6, the middle part of the outer wall of the drum 1 is provided with a ring gear 103, and the ring gear 103 is connected to the outer wall of the drum 1 through the chain 2. The first motor 4 on the support 7 is connected by transmission. The crushing device includes a rotating shaft 17 arranged at the bottom of the drum 1 and a shock absorbing device. The surface of the rotating shaft 17 is evenly provided with a cutter head 1701. The bearing seat 15 is equipped with a driven wheel 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com