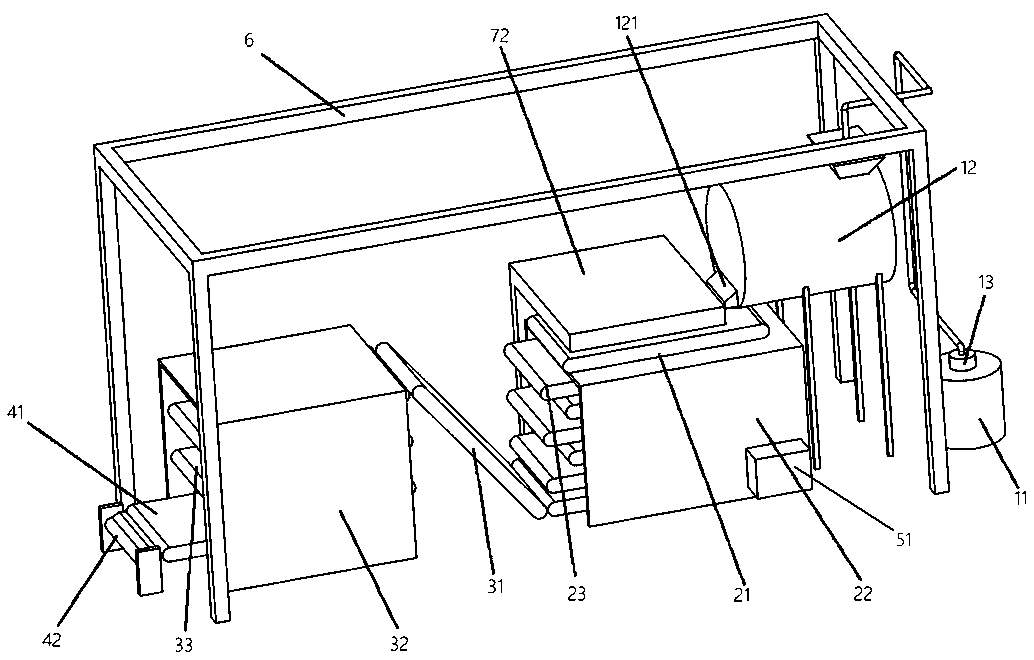

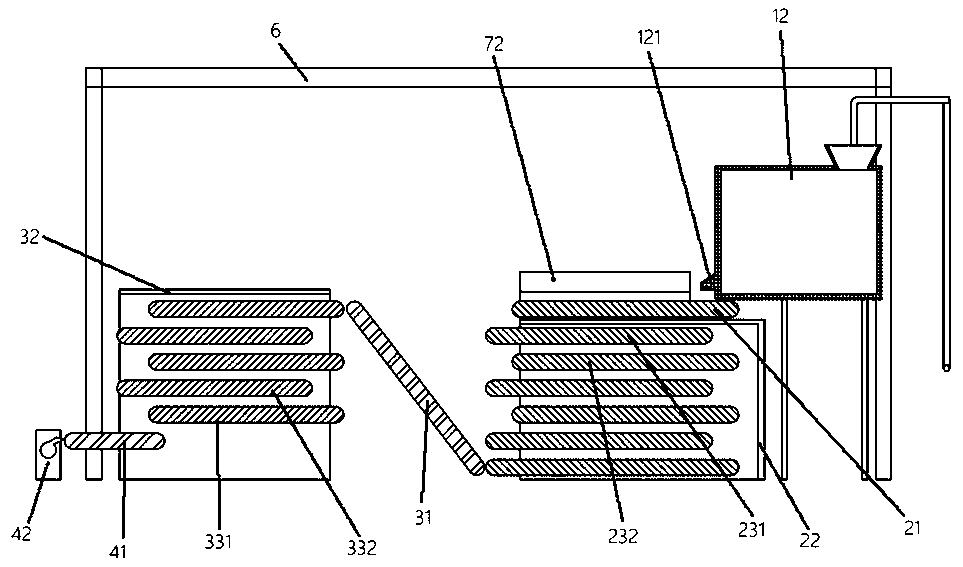

Energy-saving production line for sheet jelly

A production line and vermicelli technology, applied in the direction of food science, etc., can solve the problems of not being recycled, not being able to effectively improve the thermal efficiency, not solving the problems of heat loss and excessive energy consumption, so as to achieve a good overall drying effect and reduce waste , the effect of good energy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] The technical solution described in this embodiment is similar to that of Embodiment 1, the difference is that:

[0048] In this embodiment, there are three heat transfer devices arranged at intervals in the heat preservation and drying box 32 , and are arranged in the heat preservation and drying box 32 at equal intervals.

Embodiment 3

[0050] The technical solution described in this embodiment is similar to that of Embodiment 1, the difference is that:

[0051] In this embodiment, the production line casing 6 is provided with a negative pressure device, and the negative pressure device includes an air outlet provided on the production line casing 6 and an exhaust fan connected to the air outlet.

Embodiment 4

[0053] The technical solution described in this embodiment is similar to that of Embodiment 1, the difference is that:

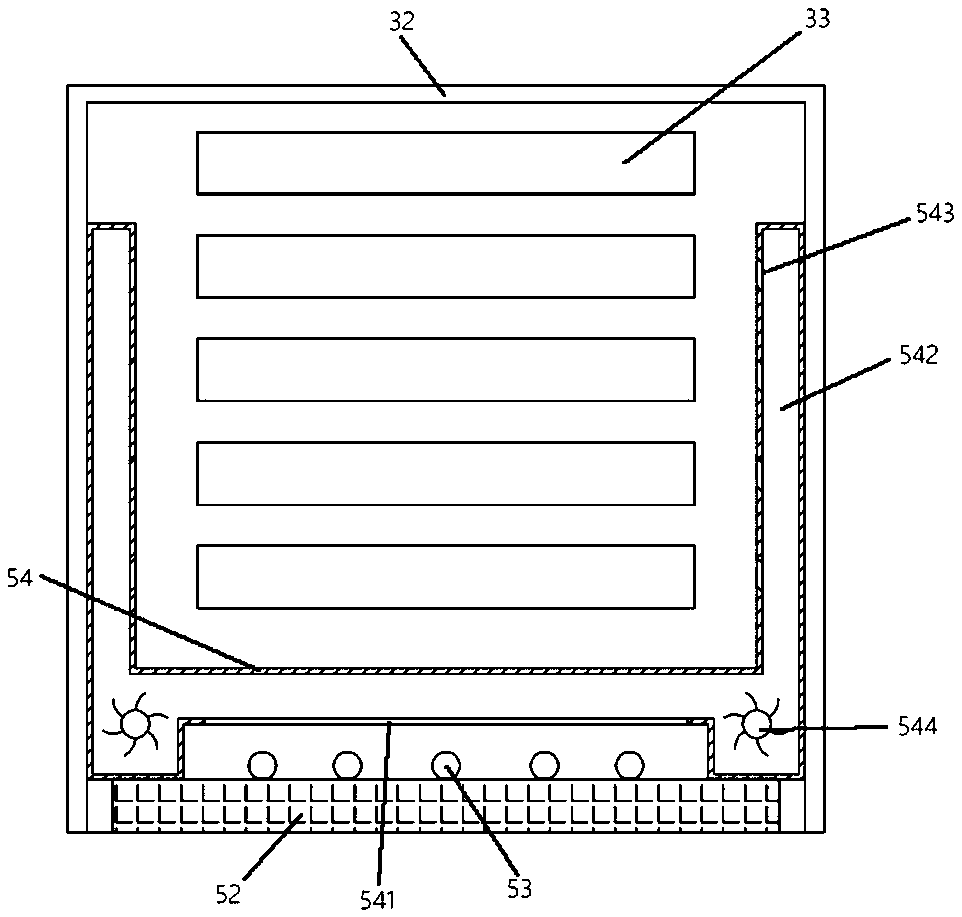

[0054] In this embodiment, the air duct 54 is disconnected at the heating wire 53 to form a separate U-shaped cross-section. The disconnected part is the air inlet 541 , and the air inlet 541 points to the heating wire 53 . In this embodiment, the horizontal air inlet 541 is set so that the heat radiation of the heating wire 53 can also be transported upward while the hot air is circulating, so as to improve the drying effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com