Preparation method and application of spice addictiVe used in cigarettes

A technology of additives and spices, applied in the field of tobacco, can solve the problems of multiple log resources, high irritation, and heavy woodiness, and achieve the effect of reducing woody odor, increasing and reducing the demand for water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

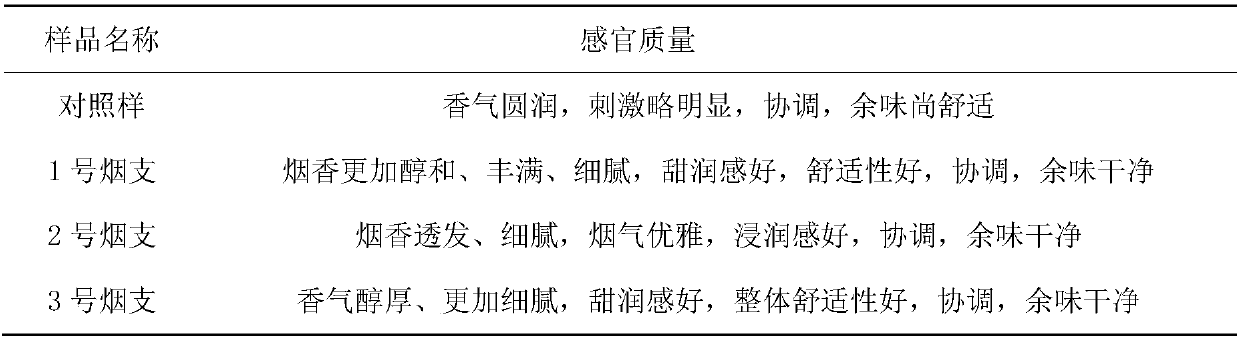

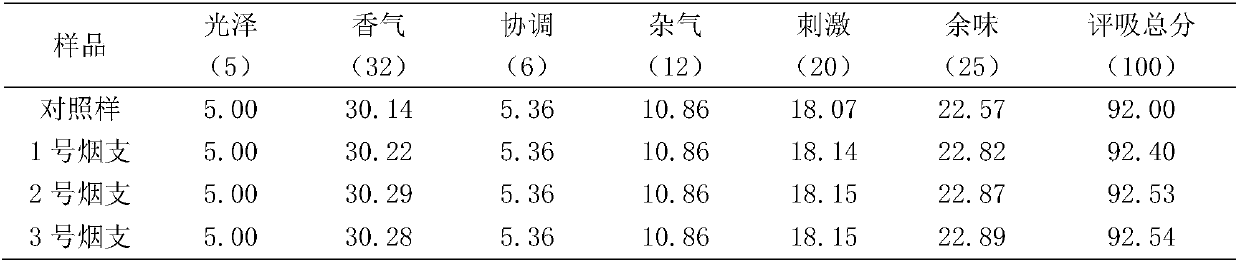

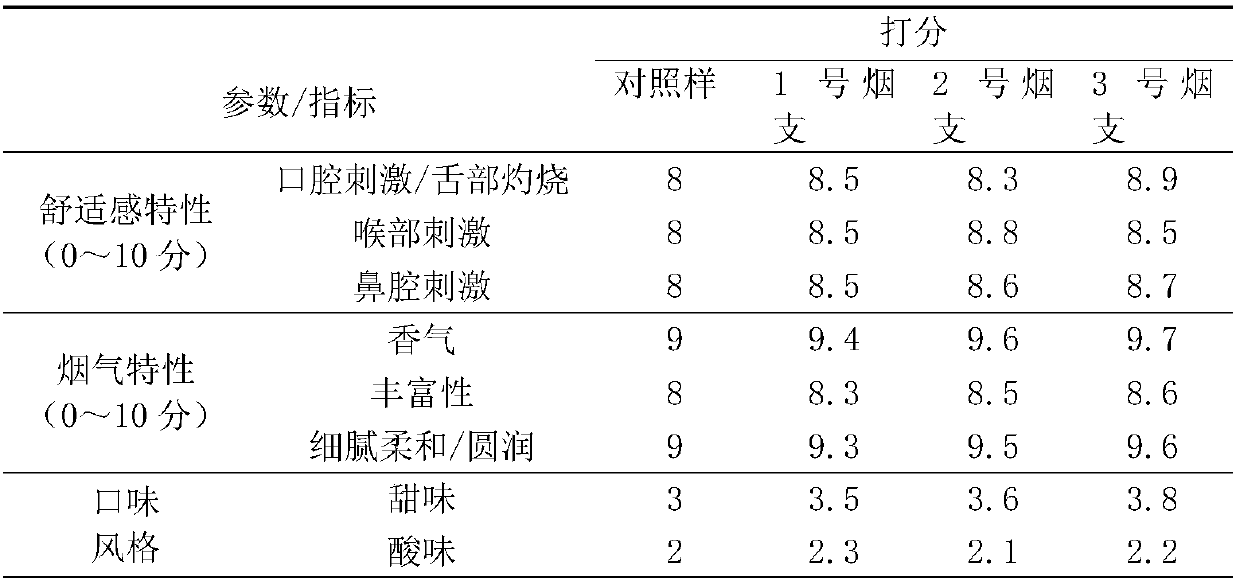

Embodiment 1

[0030] Select parts by mass: select 3 parts of loquat, 2 parts of apple, 1 part of jujube, 1 part of spinach, 2 parts of yam, 3 parts of yerba mate, and 1 part of rose, dried and then superfinely pulverized, and then used water as a solvent, The solid-liquid ratio is 1:8, and the leaching solution and insoluble matter are separated after ultrasonic leaching for 20 minutes. The leaching solution is subjected to low temperature vacuum concentration treatment for use, and the insoluble matter is immersed in 5 times of water, and then 0.03% pectinase, 0.6% amylase, 0.5% cellulase and other catalytic enzymes are added according to the total mass of the insoluble matter. , the catalytic degradation temperature was 30 °C, and the mixture was stirred for 2 hours. Then, the wood fiber is added in a mass ratio of 2% of the total mass of the insoluble matter for pulping, and then it is made into a base sheet. The leaching solution is evenly dip-coated on the above-mentioned substrate, a...

Embodiment 2

[0034] Select parts by mass: select 3 parts of plums, 1 part of grapefruit, 3 parts of bitter gourd, 1 part of geranium, and 3 parts of Pu'er tea, dry them and carry out ultra-fine grinding, and then use water as a solvent, and the solid-liquid ratio is 1:10, Ultrasonic leaching for 40 minutes. After the leaching is completed, the obtained leaching liquid and insoluble matter are separated. The leaching solution is subjected to low-temperature vacuum concentration treatment for use, and the insoluble matter and waste tobacco leaves (the mass ratio of insoluble matter and waste tobacco leaves is 1:1) are immersed again by adding 7 times of water, and then the total mass of the insoluble matter and waste tobacco leaves is calculated. Catalytic enzymes such as 0.15% pectinase, 0.3% amylase, 0.8% cellulase were respectively added, the catalytic degradation temperature was 50°C, and the mixture was stirred for 3 hours. Then, the wood fiber is added in a mass ratio of 8% of the tot...

Embodiment 3

[0038]Select parts by mass: select 2 parts of hawthorn, 3 parts of carrots, 1 part of Asian mint and 3 parts of Dianhong tea, dry them and then carry out ultrafine pulverization, then use water as a solvent, and the solid-liquid ratio is 1:15, soaked by ultrasonic The extraction was carried out for 30 minutes, and the obtained extract and insolubles were separated after the extraction. The leaching solution is subjected to low-temperature vacuum concentration treatment for use, and the insoluble matter and waste tobacco leaves (the mass ratio of insoluble matter and waste tobacco leaves is 2:1) are immersed again by adding 10 times of water, and then the total mass of the insoluble matter and waste tobacco leaves is calculated. Catalytic enzymes such as 0.1% pectinase, 0.3% amylase and 1% cellulase were respectively added, the catalytic degradation temperature was 60° C., and the mixture was stirred for 4 hours. After mixing and pulping, wood fiber is added in a mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com