Use method of stilt-type stilt

A climbing device and stilt-type technology, used in lifting devices, sports accessories, lifting frames, etc., can solve the problems of small moving range, large weight and high price, and achieve the effect of ingenious structure, light weight and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

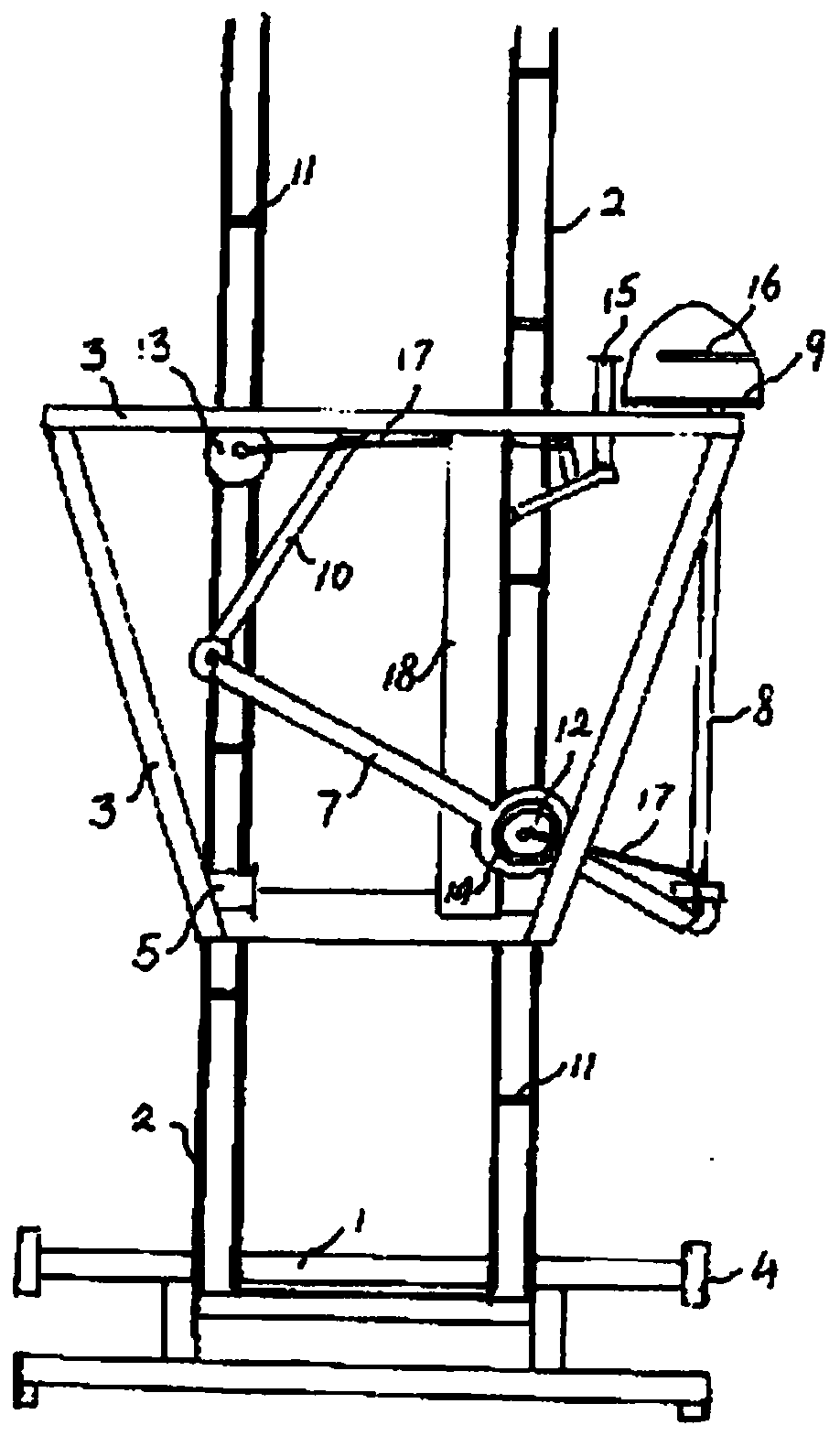

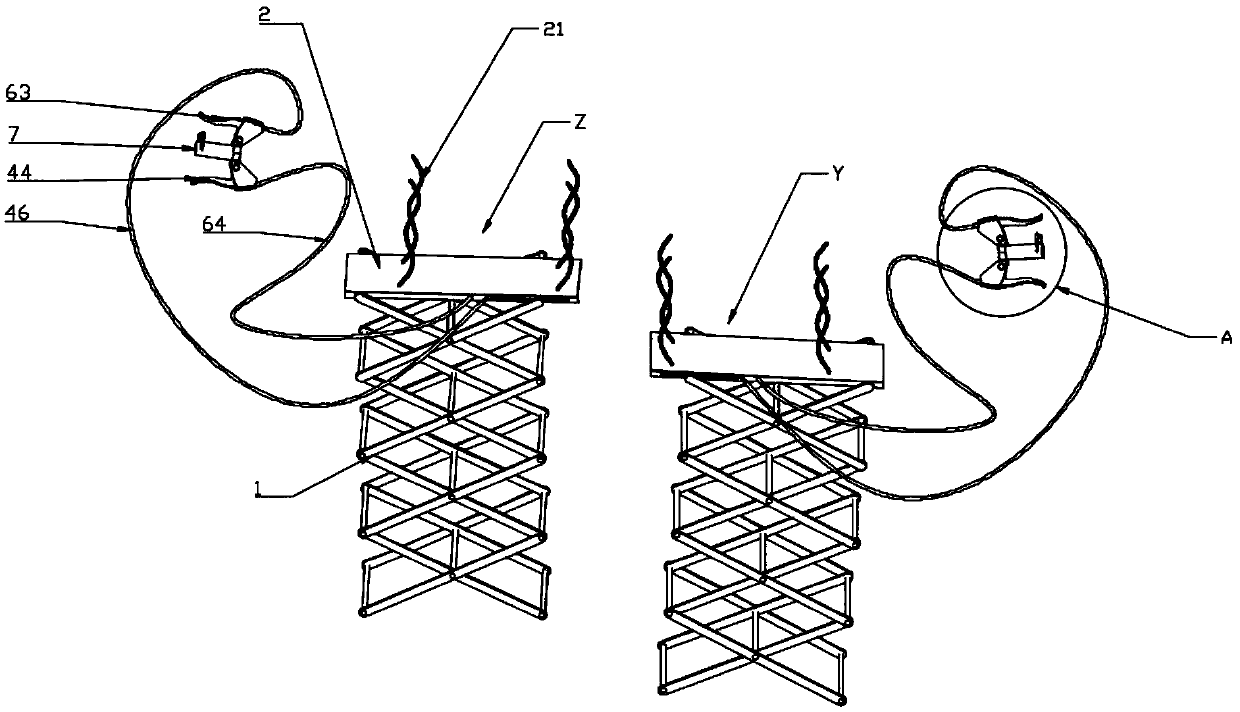

[0055] See figure 1 , The stilt-type climbing device of the first embodiment of the present invention includes: a pair of lifting devices Z, Y corresponding to the user's left foot and right foot.

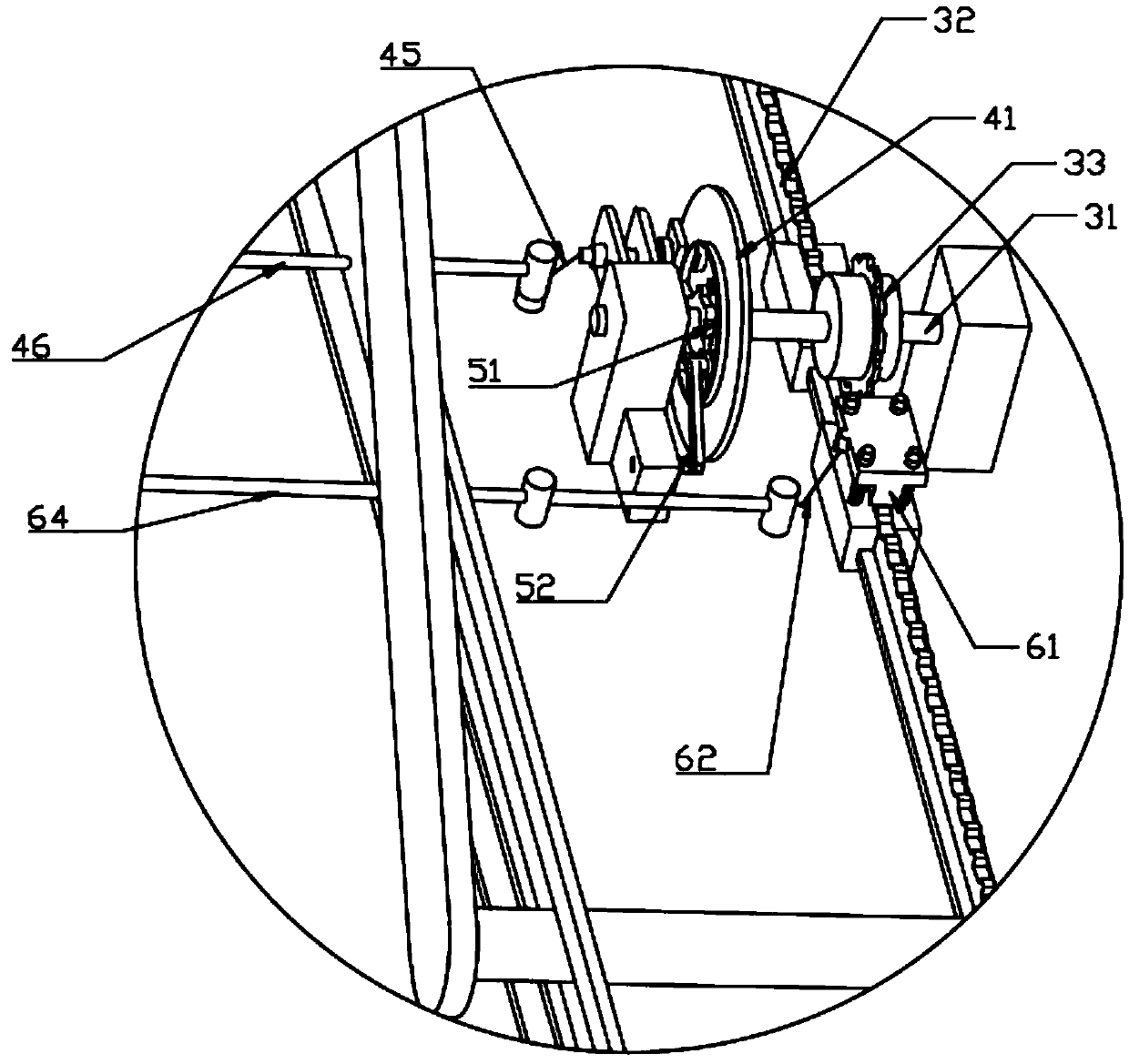

[0056] See Figure 2-13 , Lifting device Z, Y, including lifting mechanism 1, platform 2, one-way rising mechanism 3, descending clutch mechanism 4, speed reduction mechanism 5, height maintaining handbrake mechanism 6, handle 7. The scissor assembly 10 and the platform 2 of the lifting mechanism 1 are made of aluminum alloy or carbon fiber material. The one-way ascending mechanism 3 and the descending clutch mechanism 4 are located between two sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com