Cement stabilized macadam material added with illegal cooking oil and preparation method

A technology of cement-stabilized gravel and waste oil, which is applied in the field of cement-stabilized gravel materials and preparation, cement-stabilized gravel semi-rigid base materials, and can solve the problems of high cost and increased construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

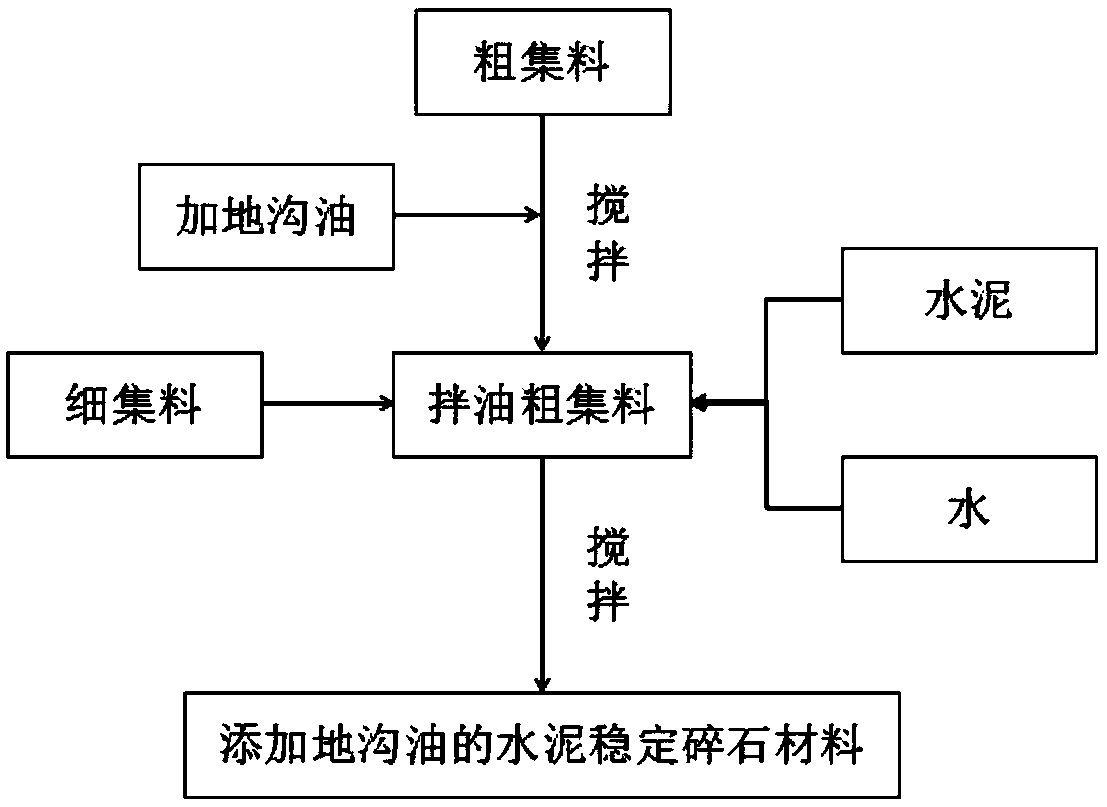

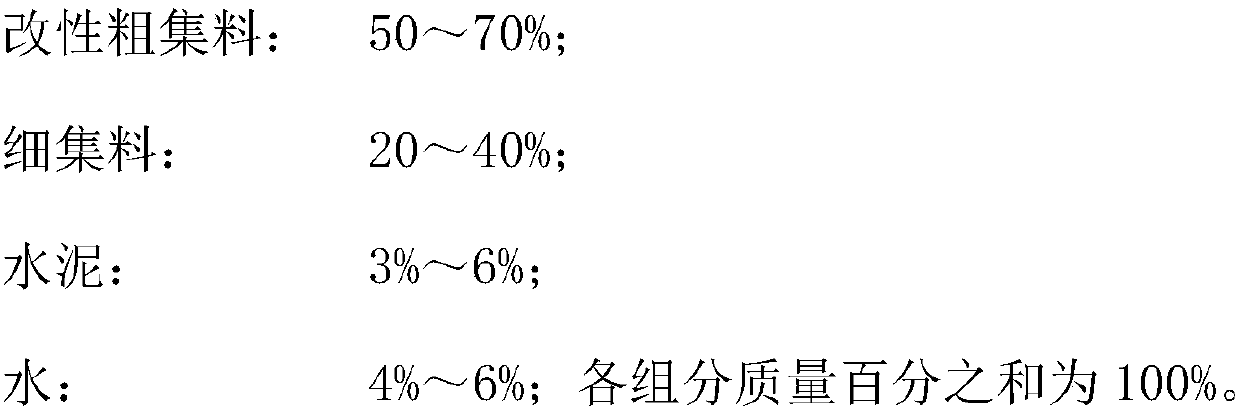

[0024] On the basis of the comparative example, the coarse aggregate is modified, and the amount of waste oil added accounts for 0.88% of the coarse aggregate, according to figure 1 Process for preparing oil-mixed cement-stabilized gravel materials, the composition formula of waste oil-modified cement-stabilized gravel materials is as follows:

[0025]

[0026] The basic performance indicators of waste oil are as follows: water content: 0.53%; solid content: 9.2%.

Embodiment 2

[0028] On the basis of Example 1, the amount of refueling is changed, and the amount of waste oil added accounts for 1.1% of the coarse aggregate, according to figure 1 Process for preparing oil-mixed cement-stabilized gravel materials, the composition formula of waste oil-modified cement-stabilized gravel materials is as follows:

[0029]

Embodiment 3

[0031] Change the ratio of coarse aggregate, fine aggregate, cement and water within the required range, the amount of waste oil added accounts for 0.88% of the coarse aggregate, and the composition formula of waste oil modified cement stabilized crushed stone material is as follows:

[0032]

[0033] Embodiment and comparative example performance contrast

[0034] The strength and flexibility properties of Comparative Example 1, Embodiment 1, Embodiment 2 and Embodiment 3 of the actual test are as follows:

[0035]

[0036] It can be seen from the table that the addition of waste oil to the coarse aggregate will lead to a slight decrease in the strength of the cement-stabilized gravel material, but it meets the requirements of the "Technical Rules for Road Pavement Base Construction" (JTG / T F20-2015). The elastic modulus decreases and the deflection at failure increases, indicating that the flexibility of the material becomes better and it can withstand more deformation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com