Pulse impacting type coordinative multi-directional rotating and rolling pressing preparation method of gradient nanocrystalline of board

A technology of pulsating impact and nanocrystals, which is applied in the field of surface strengthening and modification of metal materials, can solve the problems of insignificant surface nanotechnology, increased surface roughness, complicated operation procedures, etc., and achieves increased cumulative plastic deformation, reduced Small surface roughness, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

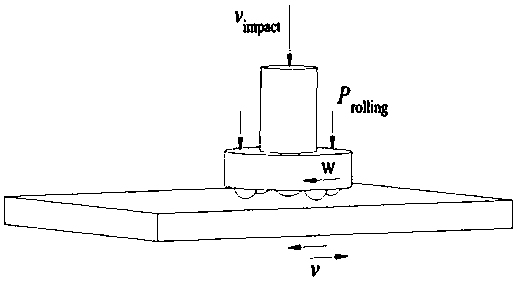

Method used

Image

Examples

Embodiment 1

[0033] (1) Keep the plate in a static state and adjust the striker parameters (pulsation impact frequency and impact velocity): for example, the impact velocity is 30m / s, the maximum equivalent plastic strain caused by impacting AISI 4340 steel is 0.11, and the minimum grain size is refined is 258.8µm, such as figure 2 shown.

[0034] (2) Keep the plate in a static state, adjust the parameters of multi-directional rotating rolling (rotation rate and static pressure): for example, the rotation rate is 5m / s, and the ball is pressed down by 3mm under the action of static pressure, the equivalent of the single rolling impact area Plastic strain and grain refinement size such as image 3 As shown, it is obvious that, compared with the single impact condition, under the synergistic effect of impact load and rolling load, the accumulated plastic deformation of the sheet increases and the refined grain size decreases.

[0035] (3) Keeping the plate in a static state, under the cond...

Embodiment 2

[0038](1) Keep the plate in a static state and adjust the striker parameters (pulsation impact frequency and impact velocity): for example, the impact velocity is 50m / s, and the equivalent plastic strain and grain refinement size caused by impacting AISI 4340 steel are as follows: Figure 5 As shown, equivalent to the working condition of the impact velocity of 30m / s, the equivalent plastic strain caused by the impact velocity of 50m / s increases, and the refined grain size decreases.

[0039] (2) Keep the plate in a static state, adjust the parameters of multi-directional rotary rolling (rotation rate and static pressure): for example, the rotation rate is 5m / s, the ball is pressed down by 5mm under the action of static pressure, and the equivalent rolling impact area of a single roll is Plastic strain and grain refinement size such as Image 6 As shown, it can be clearly seen that compared with the working condition of the ball pressing down by 3mm, the plastic deformation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com