Preparation method of bulletproof, anti-cutting and anti-flaming fabric

A technology of flame-retardant fabrics and fabrics, applied in the field of fabrics, can solve the problems of destroying the strength and modulus of aramid fiber yarns, not having bulletproof, cut-proof and flame-retardant, etc., to achieve good heat preservation effect, improve bulletproof effect, and life cycle long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: A method for preparing a bullet-proof, cut-proof and flame-retardant fabric, including the following steps:

[0045] (1) A circular knitting machine is used to weave the fabric. Both the ground yarn and the face yarn contain aramid fiber filaments. The aramid fiber filaments are filaments made of aramid 1414 fibers, that is, aramid 1414 fiber filaments. Many loop yarns are polyester fiber yarns.

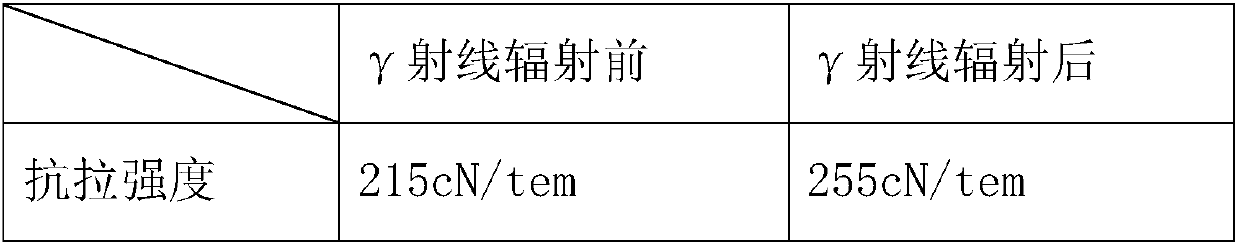

[0046] Before circular knitting, the aramid fiber yarn is irradiated with gamma rays to cause the cross-linking reaction between the skin layer and the core layer of the aramid fiber to increase the tensile strength of the aramid fiber yarn. The tensile strength comparison table of aramid fiber yarn is shown in Table 1:

[0047] Table 1: Comparison of tensile strength of aramid fiber yarn before and after γ-ray radiation

[0048]

[0049] According to Table 1, the tensile strength is the critical value for the transition of the measured object from uniform plastic deformat...

Embodiment 2

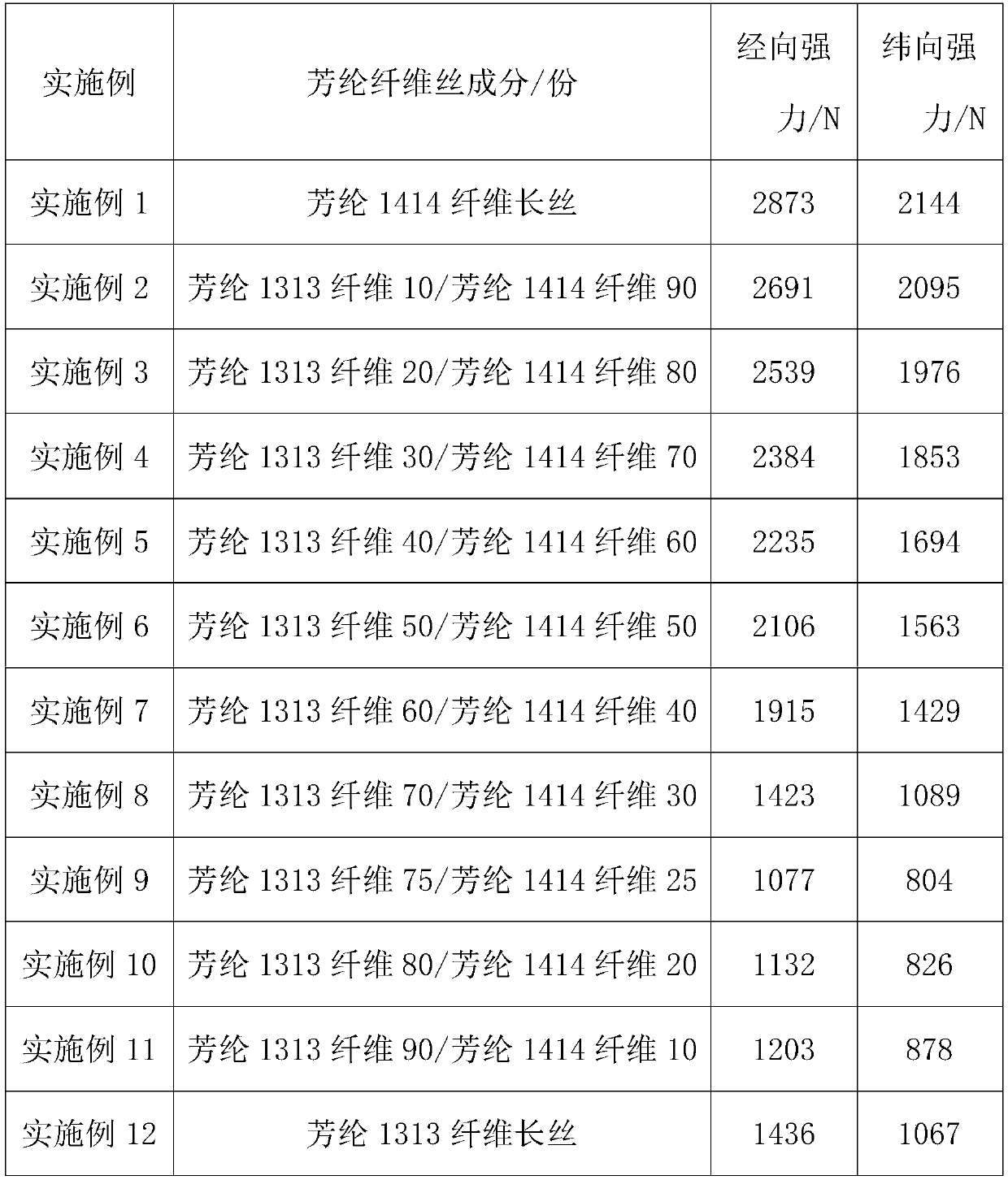

[0068] Example 2: A method for preparing a bulletproof, cut-resistant and flame-retardant fabric. The difference between this example and Example 1 is that the aramid fiber filaments in step (1) are aramid blended fibers, and the aramid blended fibers include The components in parts by weight are as follows: 10 parts of aramid 1313 fiber and 90 parts of aramid 1414 fiber.

Embodiment 3

[0069] Embodiment 3: A method for preparing a bulletproof, cut-proof and flame-retardant fabric. The difference between this embodiment and Embodiment 1 is that the aramid fiber filaments in step (1) are aramid blended fibers, and the aramid blended fibers include The components in parts by weight are as follows: 20 parts of aramid 1313 fiber and 80 parts of aramid 1414 fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com