Tunneling machine and construction method of tunneling machine

A technology of tunnel boring machine and construction method, which is applied in the direction of tunnels, earthwork drilling and mining, mining equipment, etc. It can solve the problems of not being able to achieve construction efficiency and economy, uneven geological conditions, increasing construction costs, etc., and achieve good economic benefits , Balanced force, saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

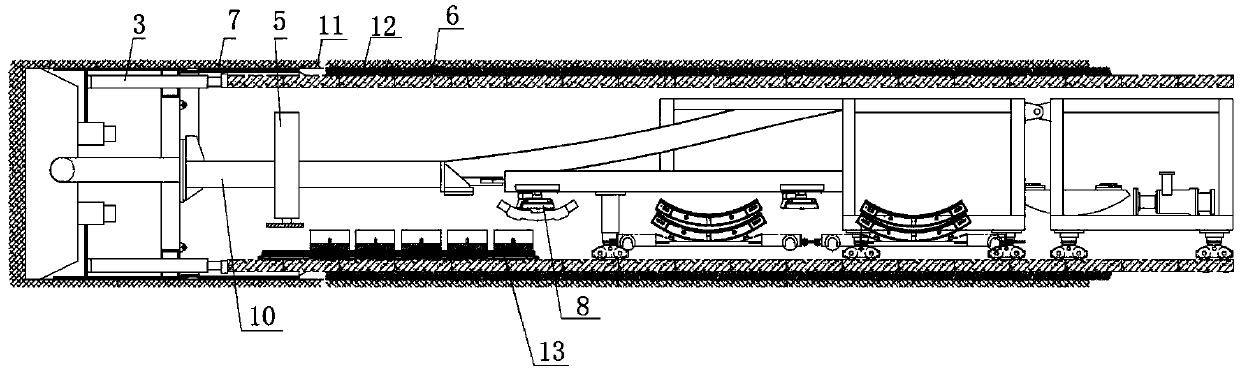

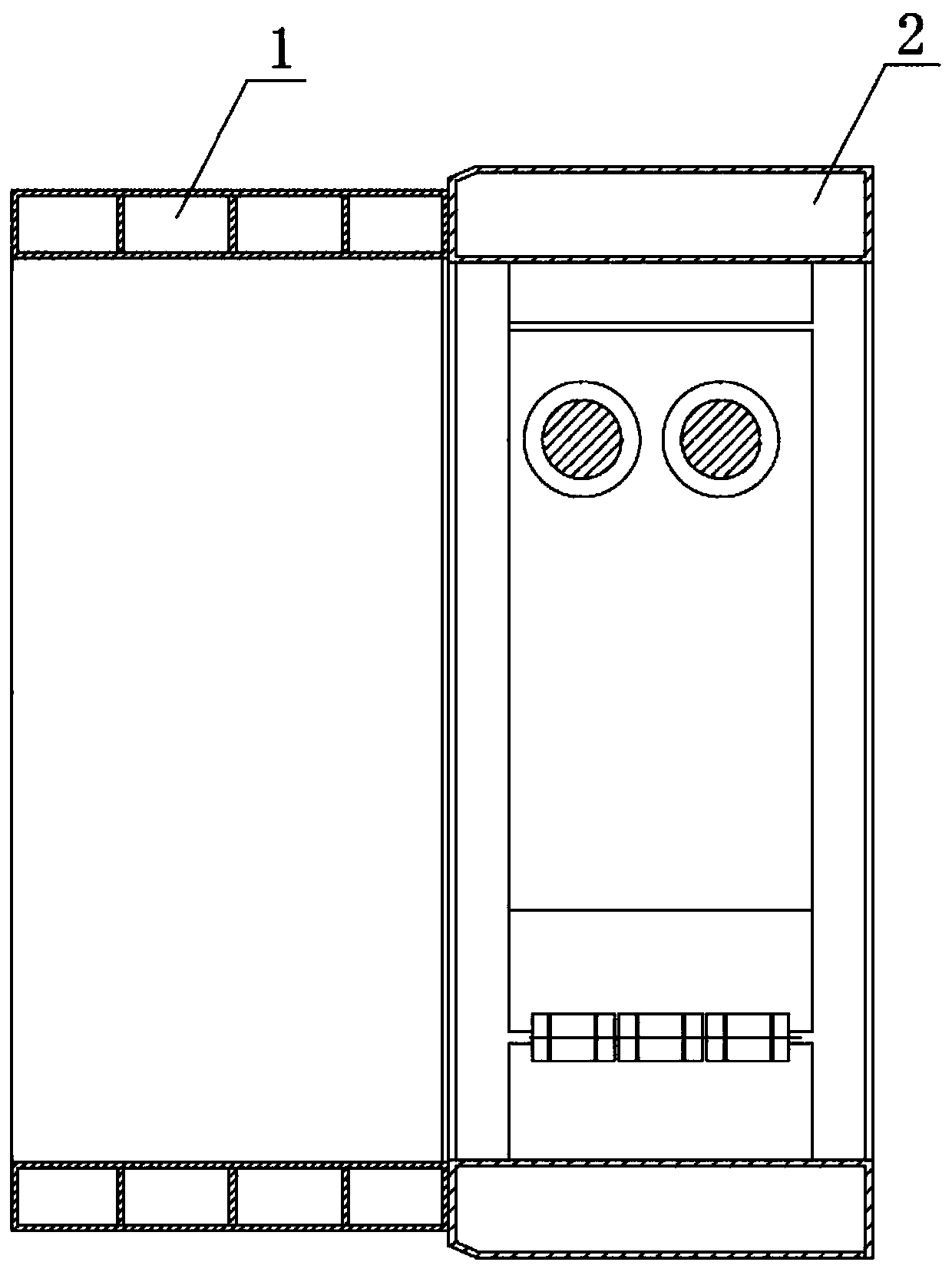

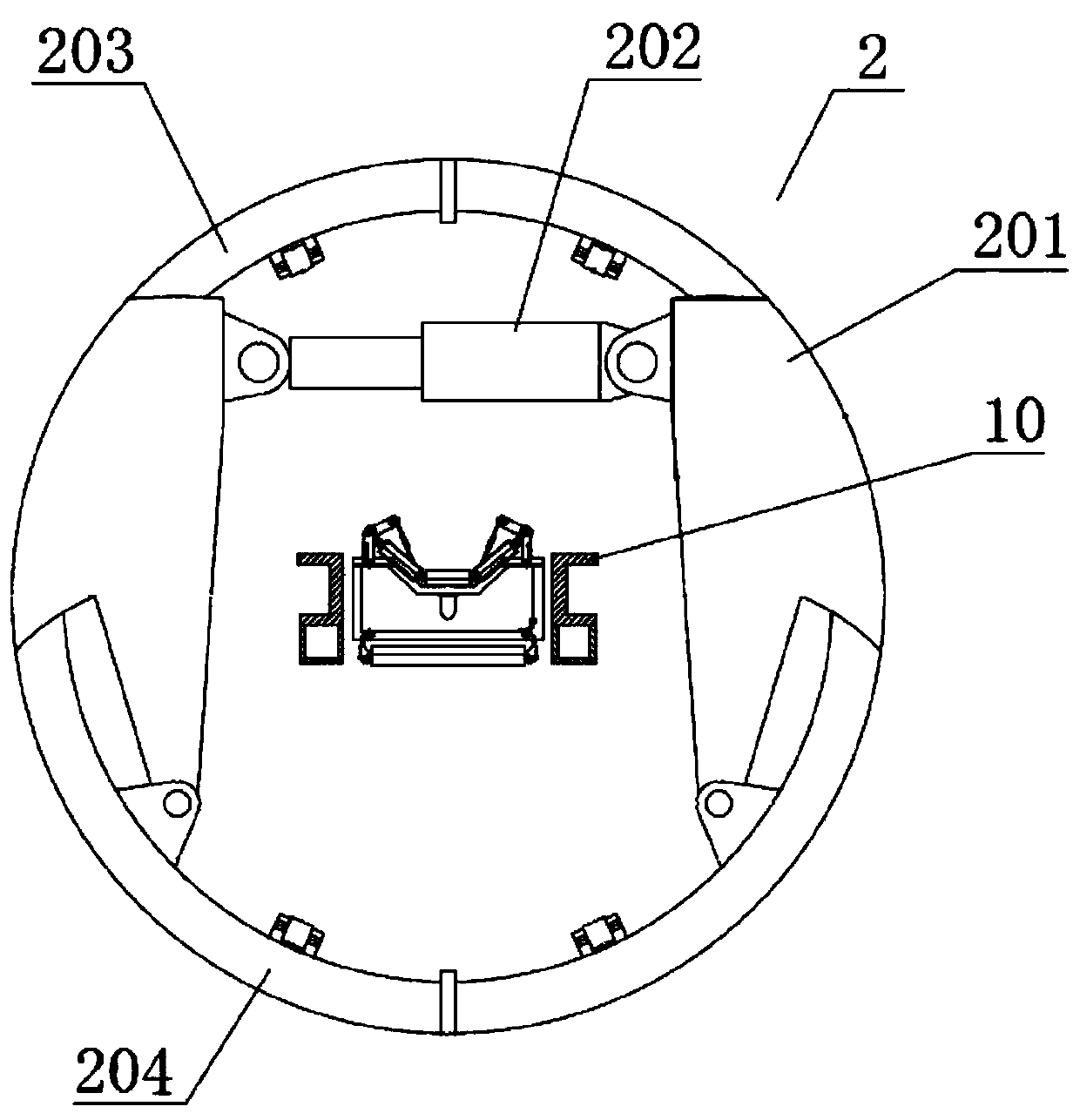

[0042] Such as Figure 1 to Figure 5 As shown, a tunnel boring machine provided in this embodiment includes a boring machine body and a tightening shield 2, a propulsion cylinder 3 is connected to the boring machine body, and the tightening shield 2 is arranged on the propulsion cylinder 3 The rear is used to tighten the tunnel to provide reverse thrust to the propulsion cylinder 3 .

[0043]The tunnel boring machine provided in this embodiment includes a boring machine body and a tensioning shield 2. A propulsion cylinder 3 is connected to the boring machine body. The tensioning shield 2 is used to support the propulsion cylinder 3 and bear the reverse thrust of the propulsion cylinder 3. During the construction of a tunnel with normal or better conditions, under the condition that the tunnel wall still has good safety and stability when the segment 6 is not assembled for lining, the tension shield 2 is directly braced on the tunnel walls on both sides of the tunnel, Rely on...

Embodiment 2

[0061] This embodiment also provides a tunnel boring machine, such as Figure 6 to Figure 14 As shown, the tunnel boring machine includes a boring machine body and a tightening shield 2, a propulsion cylinder 3 is connected to the boring machine body, and the tightening shield 2 is arranged behind the propulsion cylinder 3 for tightening Tunnel to provide reverse thrust for the propulsion cylinder 3, the outer side of the tension shield 2 is provided with a transition ring 4, the transition ring 4 is used to axially support the segment 6 assembled on the tunnel wall to balance the segment 6 axial force.

[0062] A transition ring 4 is provided, and the transition ring 4 is used to axially support the segment 6 assembled on the tunnel wall to balance the axial force of the segment 6 . In the transition section with segment 6 and without 6 construction, the ring segment 401 of the transition ring 4 can support the segment 6 under the support of the supporting structure, so as t...

Embodiment 3

[0079] A construction method of a tunnel boring machine, the method adopts the above-mentioned tunnel boring machine, and the method comprises the following steps:

[0080] Step 1. Install the body of the roadheader, the propulsion cylinder and the tension shield so that the tension shield is located at the rear of the propulsion cylinder; during the transition stage from construction with segments to no segments, the rear end of the tension shield 2 should be in line with the assembled The distance between the front end of the segment 6 on the hole wall is greater than or equal to n, where n is the adjustment width;

[0081] Step 2, tightening the cylinder 202 to push the shoe 201 to tighten on the cave wall;

[0082] Step 3: Start the body of the roadheader and the propulsion cylinder 3, and the propulsion cylinder 3 is stretched out and supported on the tension shield 2 for propulsion;

[0083] Step 4, completing the excavation distance of one excavation cycle, stopping th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com