Pump unit and high pressure cleaning machine

A pump unit, crank connecting rod mechanism technology, applied in the field of cleaning, can solve the problems of affecting life and stability, increasing the user's hand-held weight, and low supporting force, so as to increase the service life, the transmission structure is compact, and the supporting force is strengthened. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

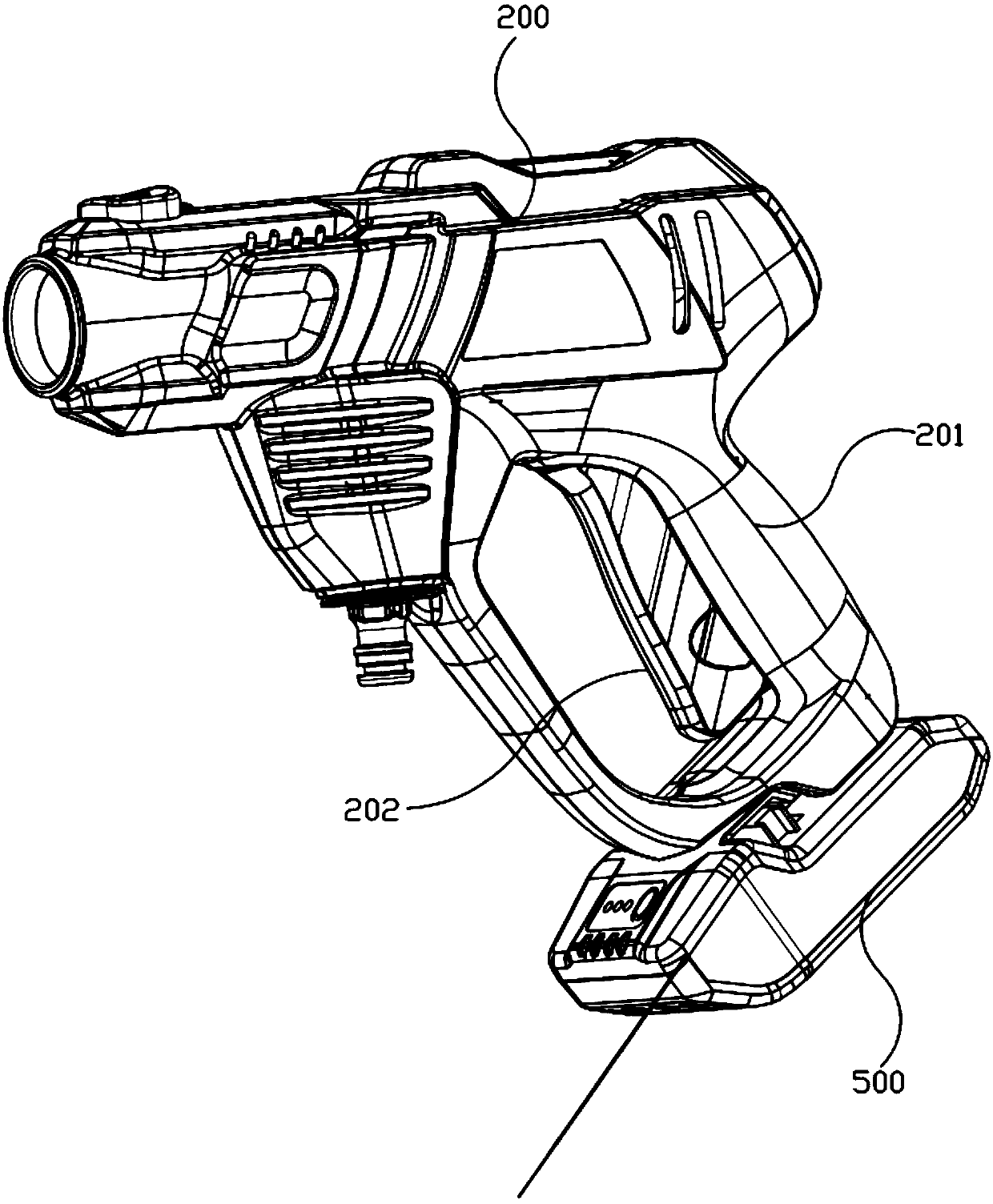

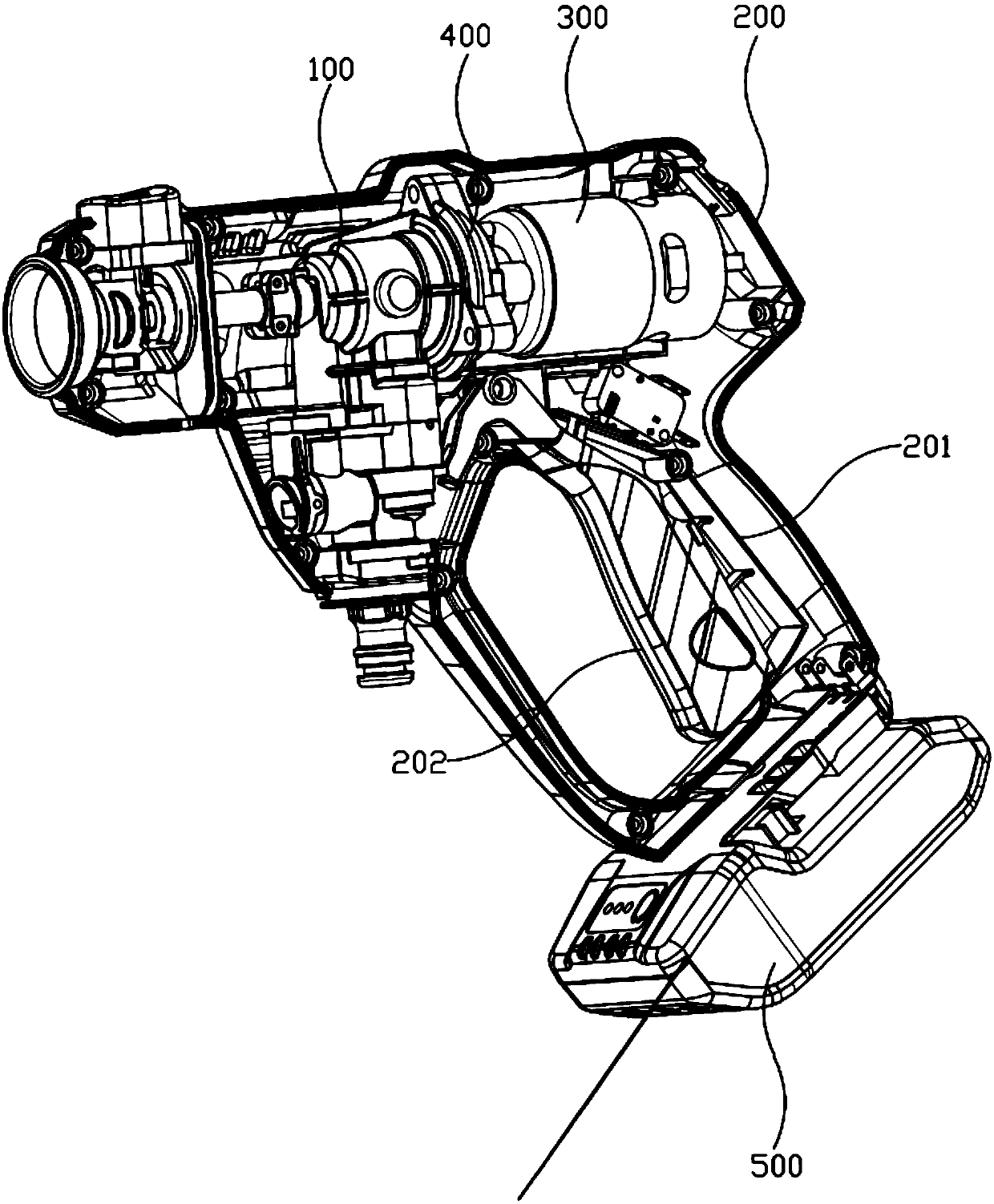

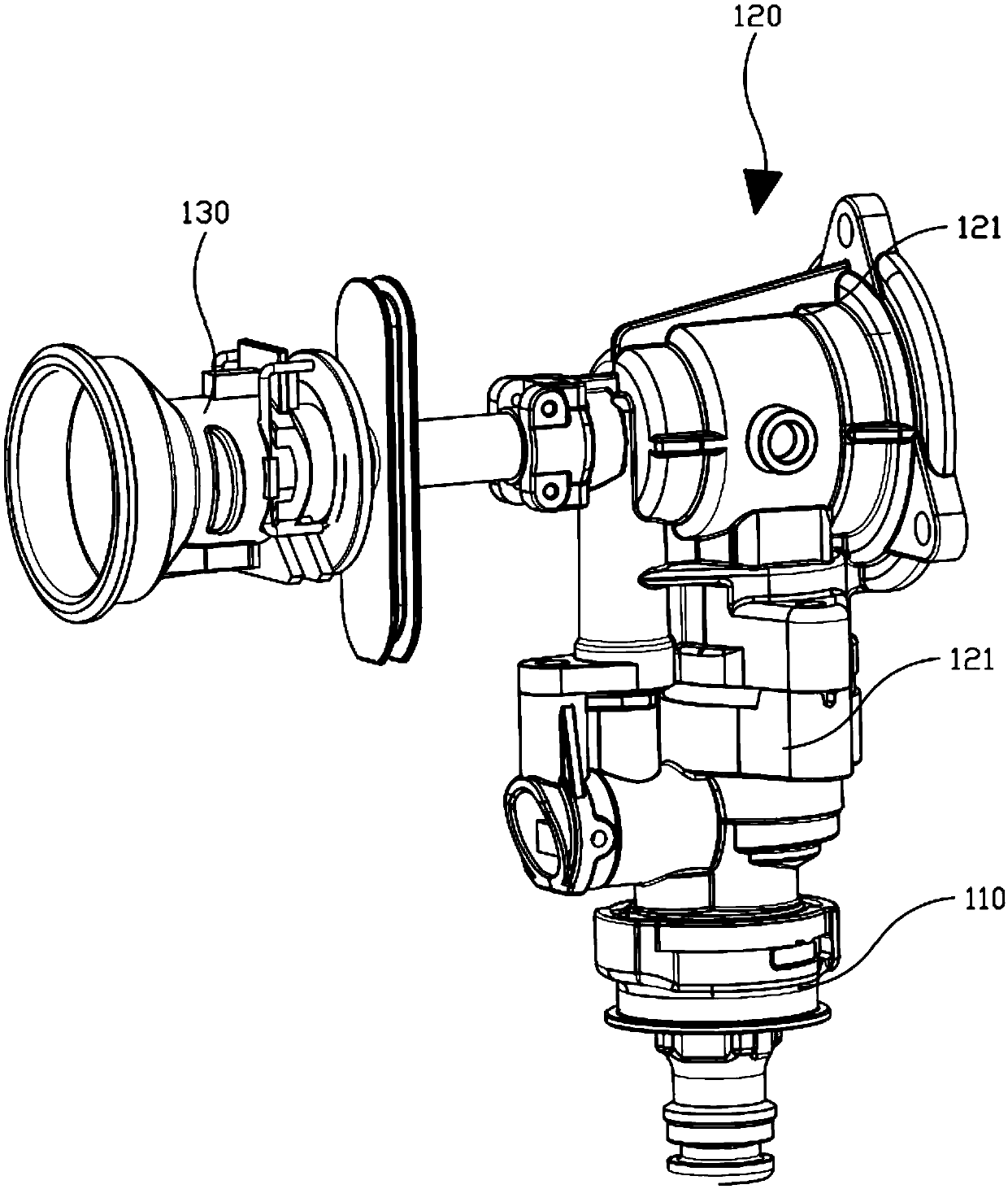

[0048] Such as Figures 1 to 2As shown, the high-pressure cleaning machine of the present invention is a hand-held type, including a housing 200, the housing 200 has a handle portion 201 for holding, and the housing 200 is provided with a motor 300, a transmission mechanism 400 connected with the motor 300, and a motor driven by the transmission mechanism 400. The pump unit 100 ; the battery pack 500 is mounted on the handle portion 201 , and the handle portion 201 is provided with a push switch 202 , and the switch 202 is electrically connected to the battery pack 500 . The high-pressure cleaner can be powered by AC or DC, and is hand-held. The shell 200 does not have a water tank for storing water, and can be connected to an external water source through a water pipe. It is small in size, light in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com