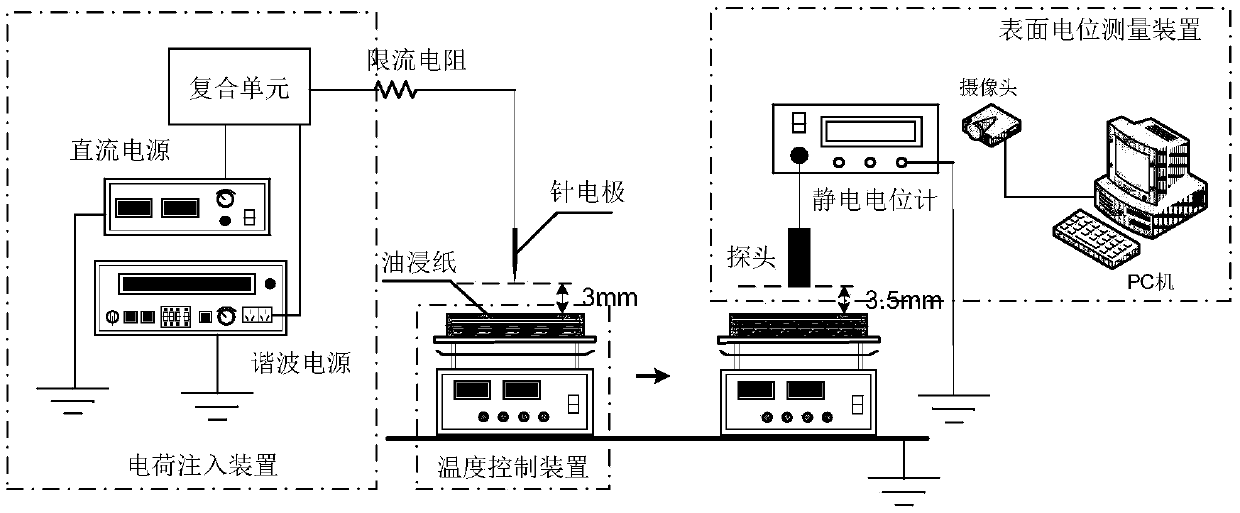

Oil-paper insulation surface charge measuring device and method based on DC superimposed harmonics

A DC superposition, oil-paper insulation technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problem of not fully considering the influence of the obvious different insulation failure characteristics of converter transformers, complex electric field distribution inside the converter transformer, and insulation problems. Research and other issues to achieve the effect of fast switching, convenient and safe experiment, and stable output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

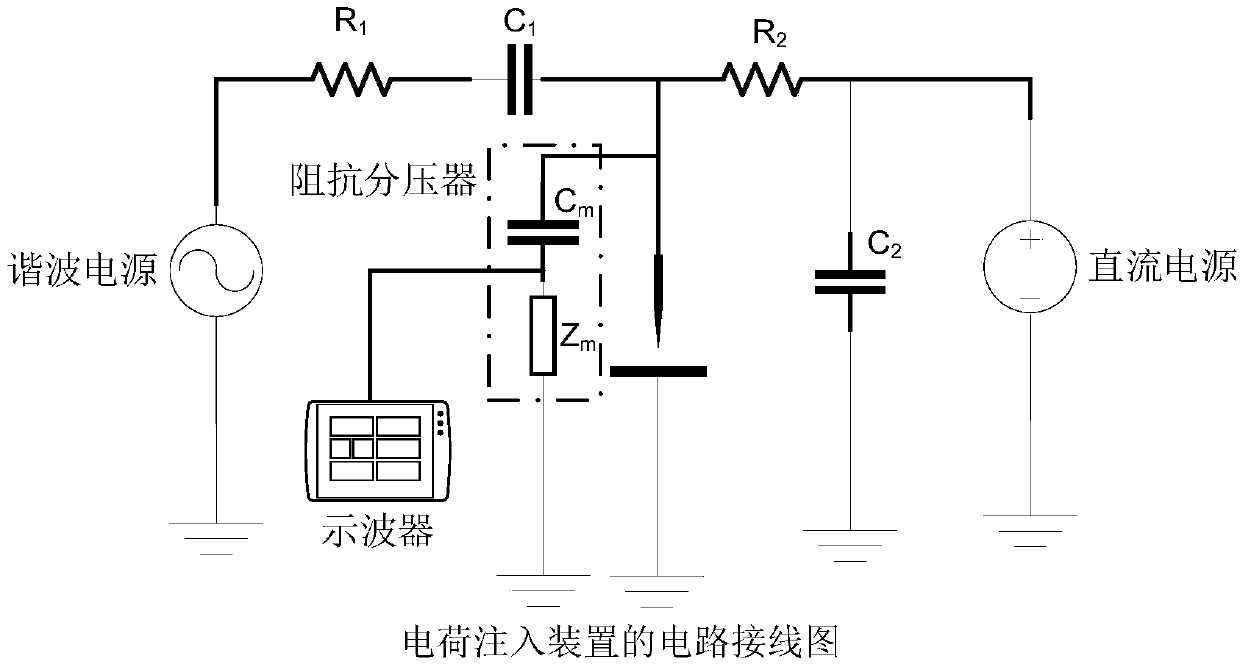

Method used

Image

Examples

Embodiment 1

[0063] The production steps of the cellulose insulating paper sample:

[0064] ①In this example, the cellulose insulating paper produced by Nantang Zhongli Co., Ltd. is used, with a thickness of 0.13mm. The cellulose insulating paper is cut into a square sample of 40mm*40mm, and the sample is placed in a model 401B thermal aging test box For drying, the temperature is set to 90° C., and the drying time is set to 12 hours.

[0065] ②Use Great Wall 25# transformer oil for vacuum oil filtering treatment.

[0066] ③Put the treated cellulose insulating paper into the transformer oil, and put it in a vacuum drying oven model DZF-6020 / 6050 for 48 hours to reduce the influence of moisture in the sample on the charge measurement; control the insulation paper and The mass ratio of insulating oil is less than 1:20, the ambient temperature is set to 40°C, and the vacuum degree is set to 50Pa.

[0067] ④ Take out the oil-impregnated insulating paper after oil-immersion treatment for subs...

Embodiment 2

[0077] 1) Sample drying: Cut the cellulose insulating paper into a square sample, put the insulating paper sample in a drying box, and dry it at 80°C for 24 hours;

[0078] 2) Oil immersion treatment: After taking out the sample, immerse the insulating paper sample in the transformer oil, and place it in an environment with a vacuum degree of 70Pa for more than 24 hours, and control the mass ratio of insulating paper to insulating oil to be less than 1:20;

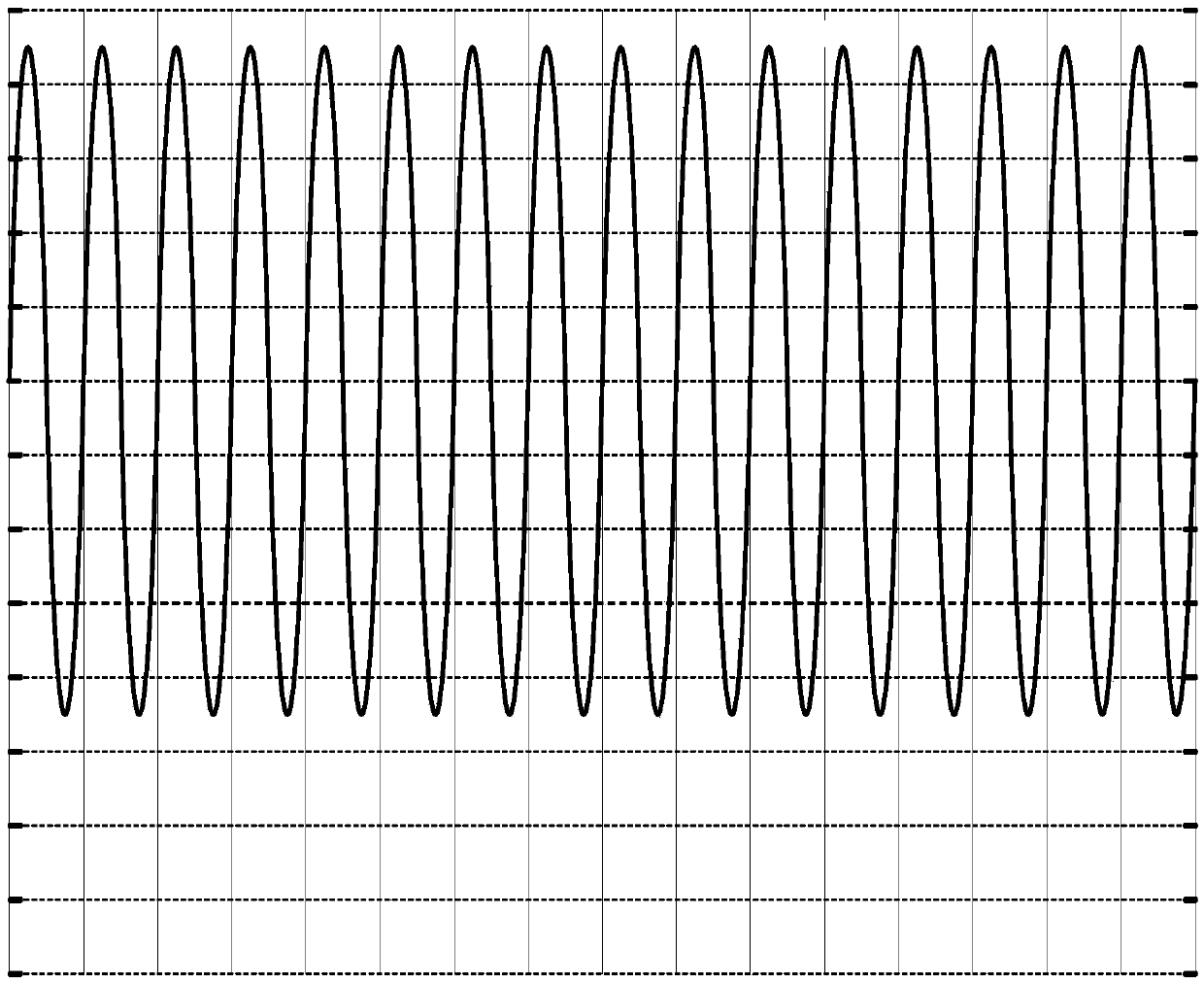

[0079] 3) Set the amplitude of the DC power supply to 4kV, and make the sum of the DC voltage amplitude and the effective value of the harmonic voltage 8kV;

[0080] 4) Set the output voltage amplitude of the harmonic power supply so that the ratio of the harmonic voltage to the amplitude of the DC voltage in step 3) satisfies 1:1, and set the frequency to 350Hz;

[0081] 5) Set the corona charging time to 4 minutes;

[0082] 6) recording: the camera is aimed at the electrostatic potentiometer screen, and the indication o...

Embodiment 3

[0087] 1) Sample drying: Cut the cellulose insulating paper into a square sample, put the insulating paper sample in a drying box, and dry it at 85°C for more than 24 hours;

[0088] 2) Oil immersion treatment: After taking out the sample, immerse the insulating paper sample in the transformer oil, and place it in an environment with a vacuum degree of 60Pa for more than 24 hours, and control the mass ratio of insulating paper to insulating oil to be less than 1:20;

[0089] 3) Set the amplitude of the DC power supply to 7kV, and make the sum of the DC voltage amplitude and the effective value of the harmonic voltage 8kV;

[0090] 4) Set the output voltage amplitude of the harmonic power supply so that the ratio of the harmonic voltage to the amplitude of the DC voltage in step 3) satisfies 1:7, and set the frequency to 150Hz;

[0091] 5) Set the corona charging time to 3 minutes;

[0092] 6) recording: the camera is aimed at the electrostatic potentiometer screen, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com