Manure discharging system used for pigpen

A technology for pigsty and manure composting, which is applied in applications, animal houses, animal husbandry, etc. It can solve problems such as lack of feed resources, high pressure on environmental protection, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

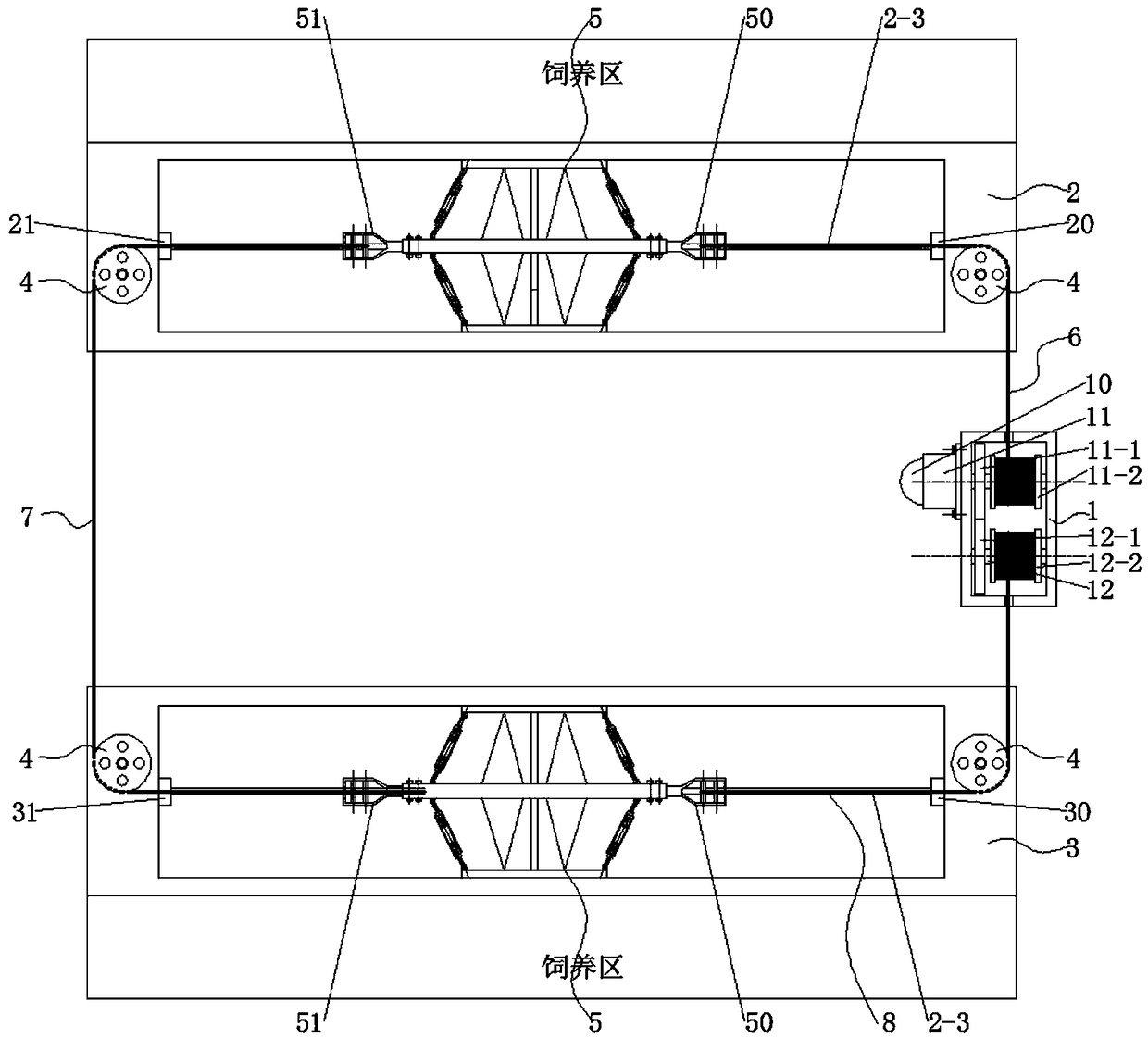

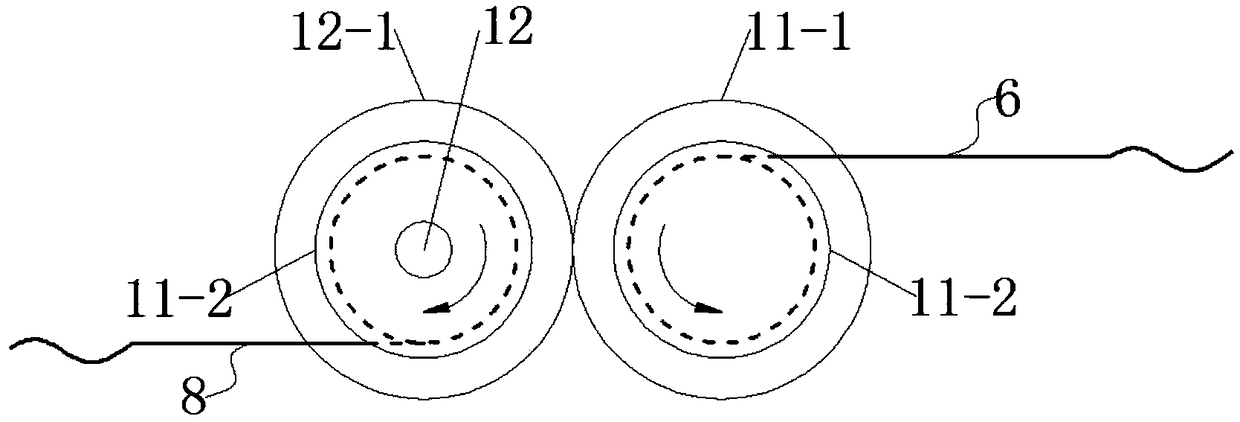

[0027]The pigsty uses a defecation system, and the workers shovel the feces of the pigs in the piggery or the pigsty in the feeding area into the septic tank 1 2 or the septic tank 2 3, and then use them as the septic tank 1 2 or the septic tank 2 3 After the piggery or pigsty in the feeding areas on both sides have been cleaned up, start the motor 10 in the drive device 1, the output shaft of the motor 10 drives the gear one 11-1 and the active winding roller 11-2 to rotate simultaneously, and then the gear One 11-1 drives the reel 12 to rotate with the passive winding roller 12-2 through the gear two 12-1, because the gear one 11-1 meshes with the gear two 12-1, and one end of the steel cable one 6 is driven from the active winding roller 12-2 to rotate. The upper end of the winding roller 11-2 bypasses the active winding roller 11-2, and is fastened with the active winding roller 11-2, and one end of the steel cable 38 bypasses the passive winding roller from the lower end o...

Embodiment 2

[0030] In the middle of the bottom of the cesspool one 2 and the cesspool two 3, a guide groove 2-3 is provided, and the bottom of the dung scraper 5 is inserted into the guide groove 2-3, which ensures that the dung scraper 5 is positioned between the cesspool one 2 and the bottom of the cesspool one 2. Linear motion in septic tank II 3.

[0031] The right end of the manure tank one 2 is provided with a limit switch one 20, the left end is provided with a limit switch two 21, the right end of the manure tank two 3 is provided with a limit switch three 30, and the left end is provided with a limit switch four 31 to ensure that the motor 10 works Stop in time to avoid pulling the dung scraper 5 strongly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com