Medicine grinding equipment for respiratory medicine department

A technology of respiratory medicine and medicine, which is applied in the direction of feeding and oral medicine appliances, etc., can solve the problems of uneven grinding and low grinding efficiency, and achieve good grinding effect, improved efficiency, and uniform grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

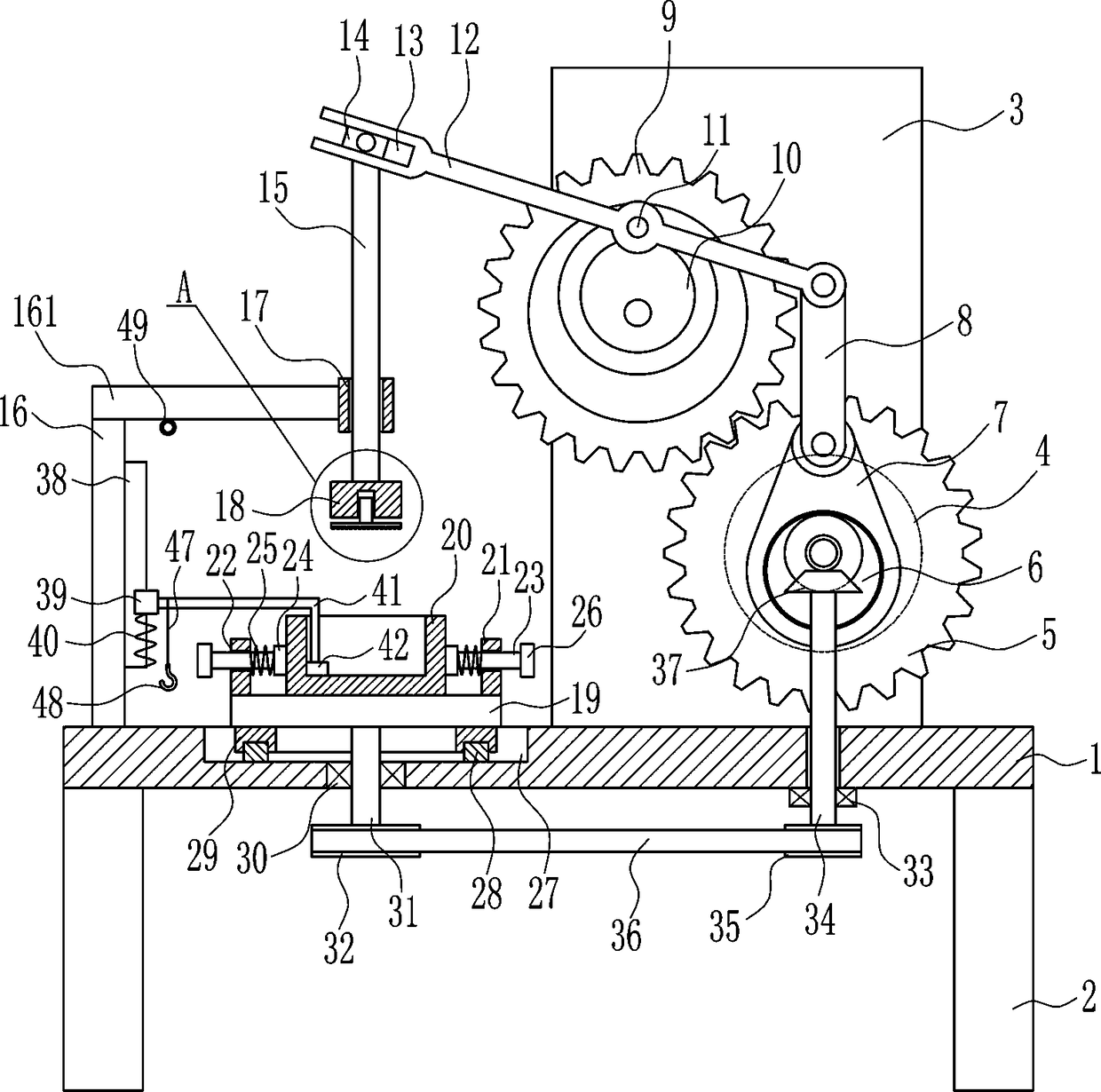

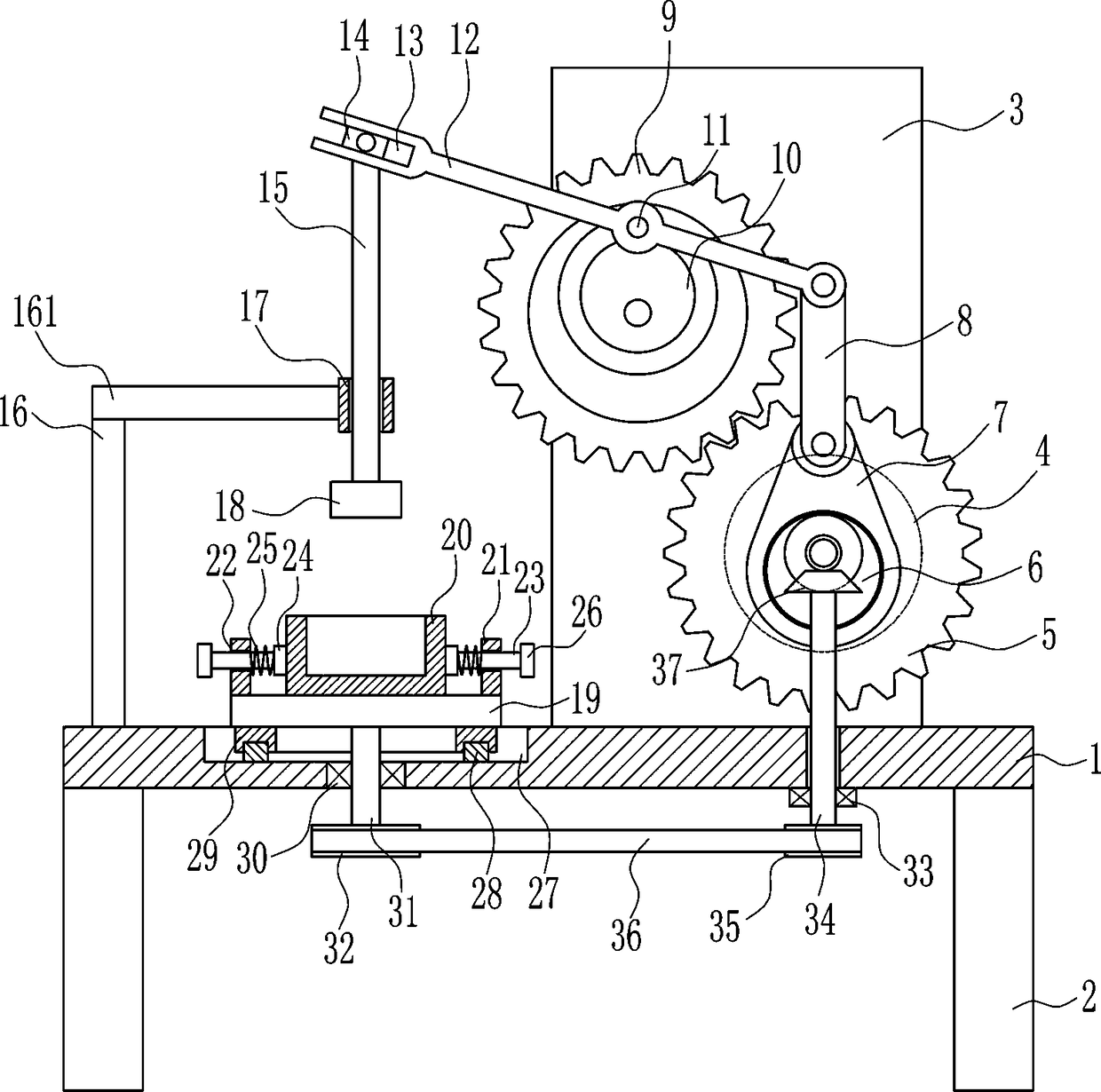

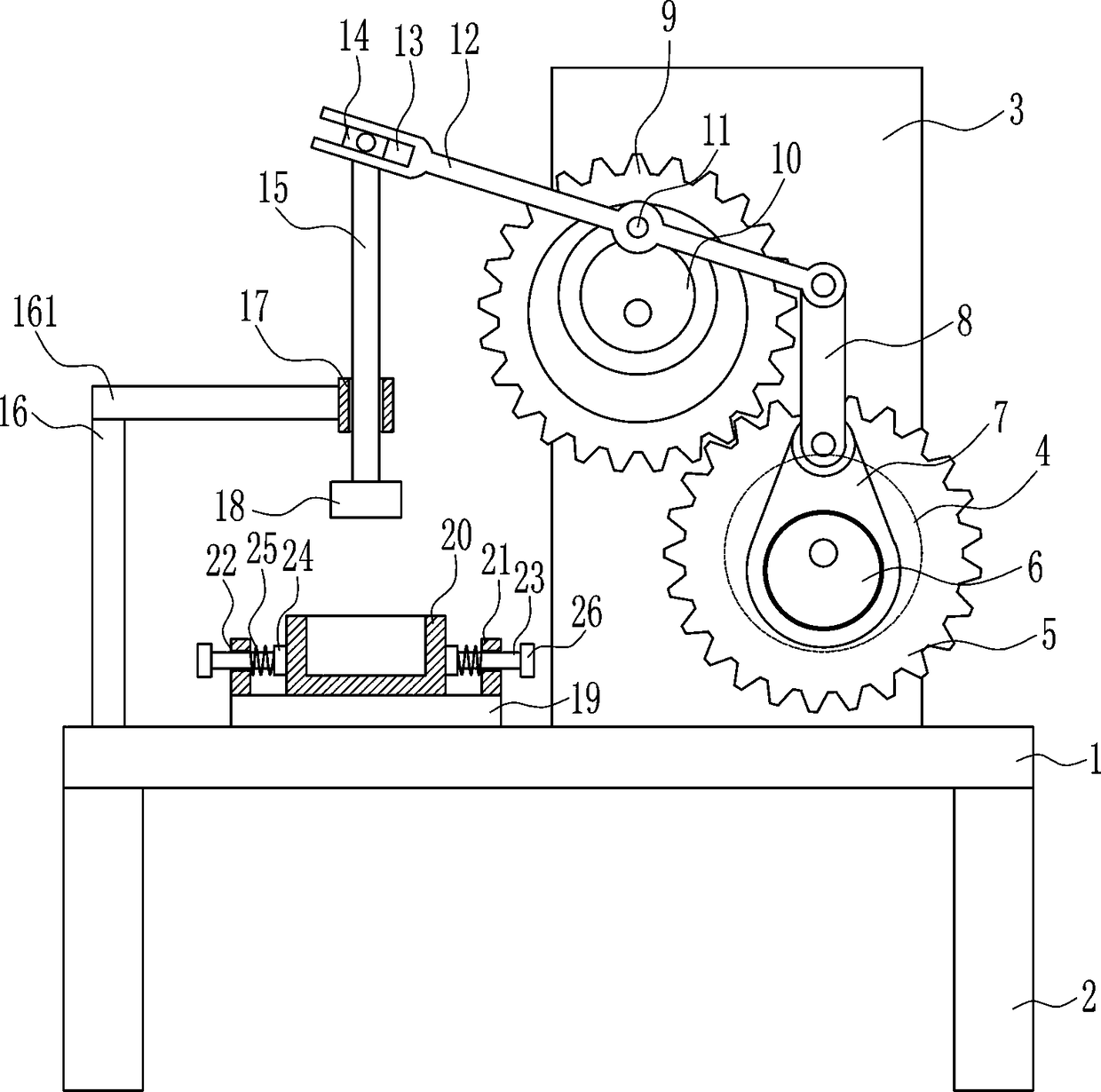

Embodiment 1

[0028] A medicine grinding device for respiratory medicine, such as Figure 1-5 As shown, it includes a bottom plate 1, a leg 2, a mounting plate 3, a motor 4, a first gear 5, a first cam 6, a rotating plate 7, a connecting rod 8, a second gear 9, a grooved cam 10, a roller 11, Swing bar 12, first slider 14, movable bar 15, vertical bar 16, cross bar 161, guide sleeve 17, placement plate 19, grinding frame 20, vertical plate 21, guide bar 23, clip block 24, first spring 25 and pull block 26, the left and right sides of the bottom of the base plate 1 are connected with supporting legs 2, the top right side of the base plate 1 is connected with the mounting plate 3, the front side of the mounting plate 3 is mounted on the lower right, and the motor 4 is installed, and the output shaft of the motor 4 is installed There is a first gear 5, the front middle part of the first gear 5 is connected with a first cam 6, the circumferential sliding of the first cam 6 is connected with a ro...

Embodiment 2

[0030] A medicine grinding device for respiratory medicine, such as Figure 1-5 As shown, it includes a bottom plate 1, a leg 2, a mounting plate 3, a motor 4, a first gear 5, a first cam 6, a rotating plate 7, a connecting rod 8, a second gear 9, a grooved cam 10, a roller 11, Swing bar 12, first slider 14, movable bar 15, vertical bar 16, cross bar 161, guide sleeve 17, placement plate 19, grinding frame 20, vertical plate 21, guide bar 23, clip block 24, first spring 25 and pull block 26, the left and right sides of the bottom of the base plate 1 are connected with supporting legs 2, the top right side of the base plate 1 is connected with the mounting plate 3, the front side of the mounting plate 3 is mounted on the lower right, and the motor 4 is installed, and the output shaft of the motor 4 is installed There is a first gear 5, the front middle part of the first gear 5 is connected with a first cam 6, the circumferential sliding of the first cam 6 is connected with a ro...

Embodiment 3

[0033] A medicine grinding device for respiratory medicine, such as Figure 1-5 As shown, it includes a bottom plate 1, a leg 2, a mounting plate 3, a motor 4, a first gear 5, a first cam 6, a rotating plate 7, a connecting rod 8, a second gear 9, a grooved cam 10, a roller 11, Swing bar 12, first slider 14, movable bar 15, vertical bar 16, cross bar 161, guide sleeve 17, placement plate 19, grinding frame 20, vertical plate 21, guide bar 23, clip block 24, first spring 25 and pull block 26, the left and right sides of the bottom of the base plate 1 are connected with supporting legs 2, the top right side of the base plate 1 is connected with the mounting plate 3, the front side of the mounting plate 3 is mounted on the lower right, and the motor 4 is installed, and the output shaft of the motor 4 is installed There is a first gear 5, the front middle part of the first gear 5 is connected with a first cam 6, the circumferential sliding of the first cam 6 is connected with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com