Cefquinome powder injection

A technology of cefquinome and powder injection, which is applied in the field of powder injection and can solve the problems of decreased water solubility and unstable crystal form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

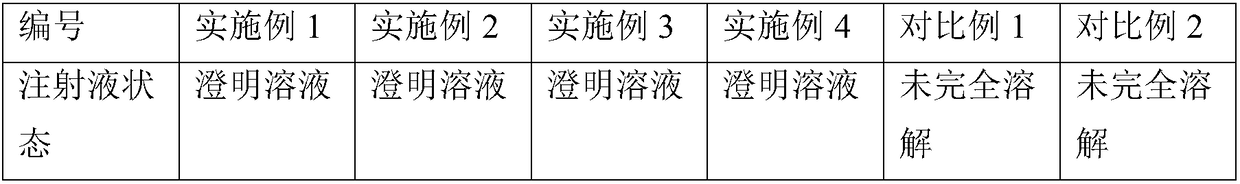

Examples

Embodiment 1

[0020] Prescription: crystalline cefquinome: 10g; polyethylene glycol 4000: 5g; N-acyl sarcosine: 0.5g.

[0021] Production process: (1) Melting: Heat polyethylene glycol 4000 to 55 degrees to melt, add crystalline cefquinome and amino acid surfactant, mix and stir for 15 minutes. Get liquid A.

[0022] (2) Cooling: Rapidly cool liquid A to below 15 degrees to obtain solid mixture B.

[0023] (3) Pulverization: Ultrafine pulverization of the solid mixture B.

[0024] (4) Mixing: The pulverized material was mixed for 30 minutes.

[0025] (5) Subpackage: Subpackage in a sterile room, the specification of subpackage is 1g / cartridge (calculated as cefquinome).

Embodiment 2

[0027] Prescription: Crystalline cefquinome: 10g; polyethylene glycol 4000: 10g; N-acyl sarcosine: 0.8g

[0028] Production process: (1) Melting: Heat polyethylene glycol 4000 to 55 degrees to melt, add crystalline cefquinome and amino acid surfactant, mix and stir for 15 minutes. Get liquid A.

[0029] (2) Cooling: Rapidly cool liquid A to below 15 degrees to obtain solid mixture B.

[0030] (3) Pulverization: The solid mixture B is mechanically pulverized.

[0031] (4) Mixing: The pulverized material was mixed for 15 minutes.

[0032] (5) Subpackage: Subpackage in a sterile room, the specification of subpackage is 1g / cartridge (calculated as cefquinome).

Embodiment 3

[0034] Composition: crystalline cefquinome: 10g; polyethylene glycol 4000: 10g; N-acyl sarcosine: 1.2g

[0035] Production process: (1) Melting: Heat polyethylene glycol 4000 to 55 degrees to melt, add crystalline cefquinome and amino acid surfactant, mix and stir for 15 minutes. Get liquid A.

[0036] (2) Cooling: Rapidly cool liquid A to below 15 degrees to obtain solid mixture B.

[0037] (3) Pulverization: The solid mixture B is mechanically pulverized.

[0038] (4) Mixing: The pulverized material was mixed for 15 minutes.

[0039] (5) Subpackage: Subpackage in a sterile room, the specification of subpackage is 1g / cartridge (calculated as cefquinome).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com