two fluid nozzle

A two-fluid, nozzle technology, applied in the direction of liquid injection devices, injection devices, etc., can solve the problems of not being able to meet economic benefits, difficult to mass-produce particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

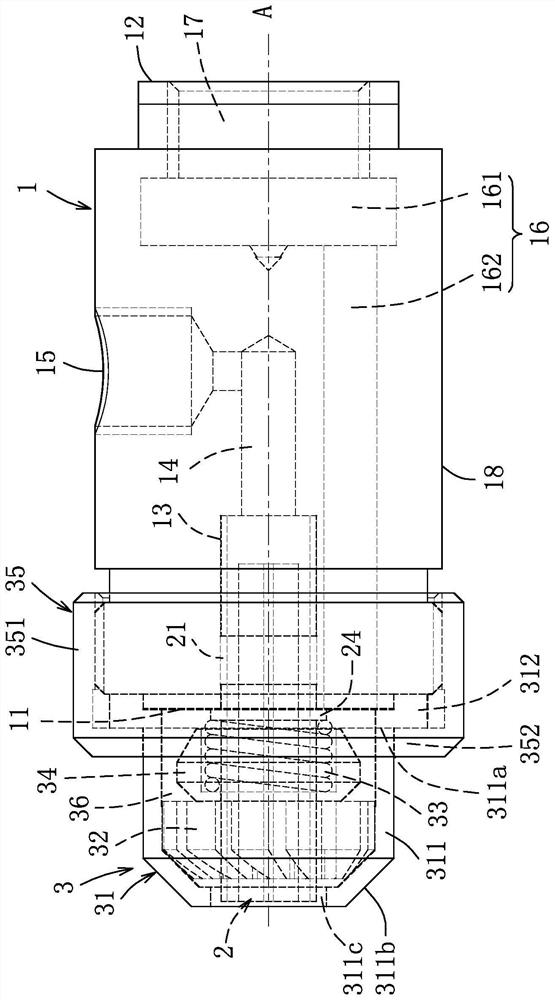

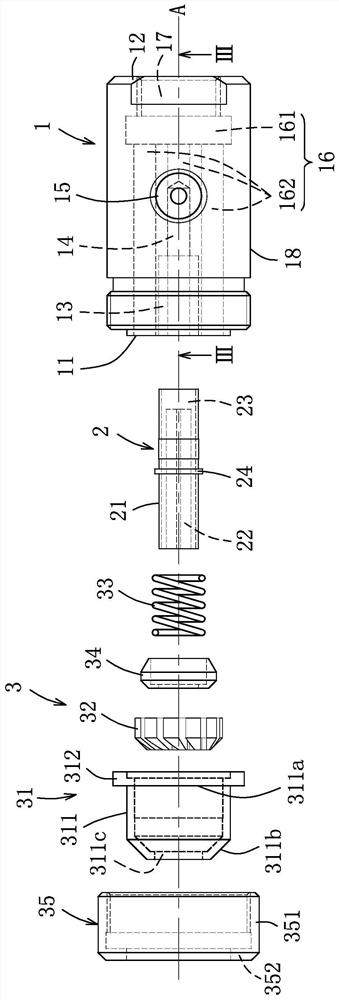

[0025] refer to figure 1 and figure 2 , an embodiment of the two-fluid nozzle of the present invention includes a base 1 , a liquid connection 2 and a confluence module 3 .

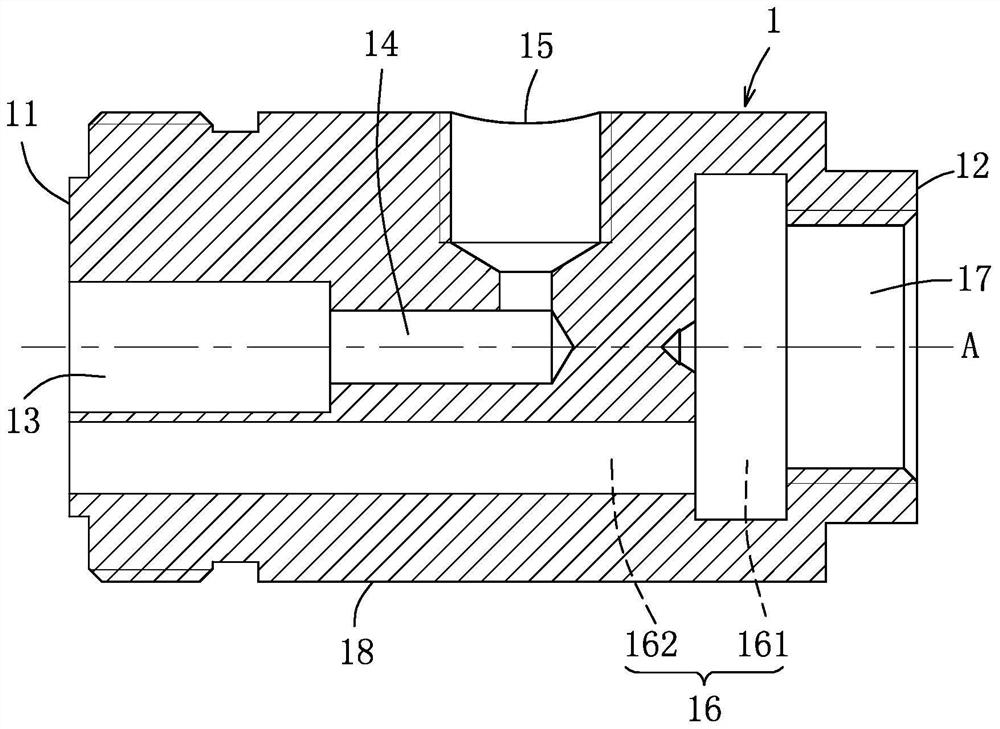

[0026] refer to image 3 and Figure 4 , the base 1 is roughly cylindrical and has a first end face 11 and a second end face 12 opposite to the first end face 11, and forms a A connecting pipe receiving groove 13 extending in the direction of the second end face 12, a liquid flow passage 14 communicating with the connecting pipe receiving groove 13, a liquid flow passage 14 communicating with the liquid flowing passage 14 and used for connecting a liquid input pipe (not shown in the figure) ) of the liquid interface 15, a gas channel 16 with a main channel part 161 and a plurality of branch channel parts 162 communicating with the main channel part 161, and a gas channel 16 communicating with the main channel part 161 and connecting a The gas interface 17 of the gas input pipe (not shown). The gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com